Rating:

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL 6D125

Engine

6D125

Serial start-end

8801--9208

Info

Injector Nozzle

093500-2710

Injector nozzle:

0935002710

KIT List:

Part name

Kit1

Kit2

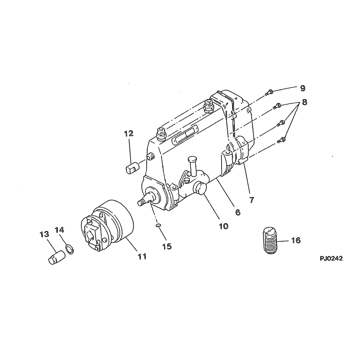

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

19100-05510

PUMP ASSY, INJECTI

A6,RSV

-8810

Include in ##:

19100-05510

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

19100-05510

PUMP ASSY, INJECTI

Information:

Table 1

Revision Summary of Changes

01 Updated Illustration 1

02 Updated effectivity Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Inadequate battery negative bonding to engine block causing incorrect diagnostic codes/tripping in the units that are disconnected from the engine-mounted charging alternator.Solution

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Illustration 1 g06575359

Generator set isolated DC supply system

(1) Electronic subsystem 1

(2) Electronic subsystem 2

(3) Electronic subsystem 3

(4) Generator set subsystem loads

(5) Engine ECM

(6) Starter

(7) Electronics power buss

(8) Electronics single point ground

(9) 12AWG (4 Sq.mm) bonding jumper (multi strand) wire

(10) Battery disconnect switch

(11) Customer ground connection

(12) Battery

(13) Battery charger

(14) Customer scopeNote: The red color connections in Illustration 1 are to be connected at customer site. Connections should be made after the battery disconnect switch (10).Caterpillar is aware of the problem, and is recommending the following interim solution.Install a 12AWG (4 Sq.mm) bonding jumper (multi strand) wire (9) connecting all electrical sensor grounding points (8) at the power distribution box to the customer ground connection (11). Refer to Illustration 1.Reference: Refer to Special Instruction, REHS4634, "Grounding Design Guide for Electric Power Generation Products".