Rating:

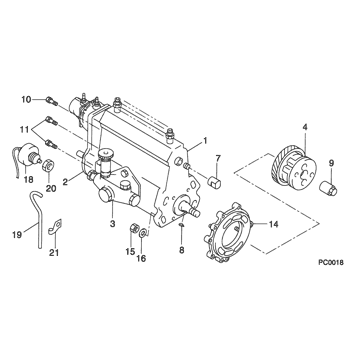

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

LAND CRUISER 2H

Engine

2H

Serial start-end

8409-

Info

Injector Nozzle

093500-3020

TOYOTA

PUMP ASSY, INJECTI

AA

- * THIS PUMP IS A SPAIR PUMP OF 093000-1030

- (WITHOUT TIMER).

Injector nozzle:

0935003020

KIT List:

Part name

Kit1

Kit2

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

19000-09240

PUMP ASSY, INJECTI

A6,COMB

22100-68041

TOYOTA

Include in ##:

19000-09240

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

19000-09240

22100-6804

TOYOTA

PUMP ASSY, INJECTI

1900009240

22100-68041

TOYOTA

PUMP ASSY, INJECTI

Information:

General Hazard Information

Attach a "DO NOT OPERATE" or similar warning tag to start switch or controls before servicing or repairing the truck engine. These tags, Form SEHS7332, are available from your Caterpillar dealer.Do not allow unauthorized personnel in the truck when it is being serviced.Tampering with the 3406B PEEC system installation or the truck OEM wiring installation can be dangerous and could result in personal injury or death and/or engine damage.The use of high powered or illegal radio transmitter equipment in a 3406B PEEC equipped vehicle may interfere with proper operation of the 3406B PEEC system. Properly installed and functioning auxiliary equipment such as CB radios, high output FM stereos, radar detectors, etc. should not prevent proper operation of the PEEC system.The 3406B PEEC uses high voltage to the unit injectors. Do not come in contact with the injector terminals while the engine is running.When operating the engine in a closed area, vent the exhaust to the outside.If the engine is not running, do not release the secondary or parking brake systems unless the truck is blocked or restrained.Wear a hard hat, protective glasses and other protective equipment as required by job conditions.Do not wear loose clothing or jewelry that can catch on controls or other parts of the engine.Make certain all protective guards and covers are secured in place.Use all cleaning solutions with care.Never put maintenance fluids into glass containers since glass containers can break.Report all needed repairs.* Stop the engine.* Ensure the protective locks or controls are in the applied position.* Apply the secondary (emergency) and parking brakes.* Block or restrain the vehicle before servicing.* Disconnect the batteries before servicing the electrical system.* Do not attempt repairs you do not understand.* Use proper tools and replace or repair broken or damaged equipment.* When starting an engine after repairs have been made to the fuel system, make provisions for shutting off the engine's intake air supply, (to stop the engine), in case there is an overspeed on start-up.* Start the engine only from the operator's station (cab). Never short across the starter terminals or the batteries as this could bypass the engine neutral-start system as well as damage the electrical system.Pressure Air and Water

Pressure air can cause personal injury. When using pressure air for cleaning, wear a protective face shield, protective clothing and protective shoes.The maximum air pressure must be below 30 psi (205 kPa) for cleaning purposes.Wear eye protection at all times when cleaning the cooling system. Pressurized water could cause debris and/or hot water to be blown and result in personal injury.Fluid Penetration

Always use a board or cardboard when checking for a leak. Escaping fluid under pressure, even a pin-hole size leak, can penetrate body tissue, causing serious injury, and possible death.If fluid is injected into your skin, it must be treated by a doctor familiar with this type of injury immediately.Asbestos Information

Caution should be used to avoid breathing dust that may be generated when handling components containing asbestos fibers. If this dust is inhaled,

Attach a "DO NOT OPERATE" or similar warning tag to start switch or controls before servicing or repairing the truck engine. These tags, Form SEHS7332, are available from your Caterpillar dealer.Do not allow unauthorized personnel in the truck when it is being serviced.Tampering with the 3406B PEEC system installation or the truck OEM wiring installation can be dangerous and could result in personal injury or death and/or engine damage.The use of high powered or illegal radio transmitter equipment in a 3406B PEEC equipped vehicle may interfere with proper operation of the 3406B PEEC system. Properly installed and functioning auxiliary equipment such as CB radios, high output FM stereos, radar detectors, etc. should not prevent proper operation of the PEEC system.The 3406B PEEC uses high voltage to the unit injectors. Do not come in contact with the injector terminals while the engine is running.When operating the engine in a closed area, vent the exhaust to the outside.If the engine is not running, do not release the secondary or parking brake systems unless the truck is blocked or restrained.Wear a hard hat, protective glasses and other protective equipment as required by job conditions.Do not wear loose clothing or jewelry that can catch on controls or other parts of the engine.Make certain all protective guards and covers are secured in place.Use all cleaning solutions with care.Never put maintenance fluids into glass containers since glass containers can break.Report all needed repairs.* Stop the engine.* Ensure the protective locks or controls are in the applied position.* Apply the secondary (emergency) and parking brakes.* Block or restrain the vehicle before servicing.* Disconnect the batteries before servicing the electrical system.* Do not attempt repairs you do not understand.* Use proper tools and replace or repair broken or damaged equipment.* When starting an engine after repairs have been made to the fuel system, make provisions for shutting off the engine's intake air supply, (to stop the engine), in case there is an overspeed on start-up.* Start the engine only from the operator's station (cab). Never short across the starter terminals or the batteries as this could bypass the engine neutral-start system as well as damage the electrical system.Pressure Air and Water

Pressure air can cause personal injury. When using pressure air for cleaning, wear a protective face shield, protective clothing and protective shoes.The maximum air pressure must be below 30 psi (205 kPa) for cleaning purposes.Wear eye protection at all times when cleaning the cooling system. Pressurized water could cause debris and/or hot water to be blown and result in personal injury.Fluid Penetration

Always use a board or cardboard when checking for a leak. Escaping fluid under pressure, even a pin-hole size leak, can penetrate body tissue, causing serious injury, and possible death.If fluid is injected into your skin, it must be treated by a doctor familiar with this type of injury immediately.Asbestos Information

Caution should be used to avoid breathing dust that may be generated when handling components containing asbestos fibers. If this dust is inhaled,