Rating:

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL 2J

Engine

2J

Serial start-end

8208--8807

Info

Injector Nozzle

093500-1810

Injector nozzle:

0935001810

KIT List:

Part name

Kit1

Kit2

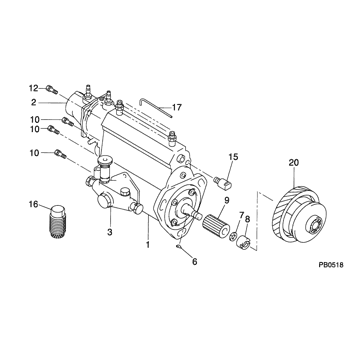

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

19000-07020

PUMP ASSY, INJECTI

A4,MN

22100-41812-71

TOYOTA

Include in ##:

19000-07020

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

19000-07020

22100-4181

PUMP ASSY, INJECTI

1900007020

22100-41812-71

TOYOTA

PUMP ASSY, INJECTI

Information:

Possible Causes/Corrections Cold Outside Temperatures

It may be necessary to use starting aids, or to heat engine oil or coolant at temperatures below -12°C (10°F). Air In Fuel SystemWith air in the fuel system, the engine will normally be difficult to start, run rough, and release a large amount of white smoke. If the engine will not start, loosen a fuel injection line nut at the through the head adapter and crank the engine until fuel comes out. Tighten the fuel line nut. Start the engine. If the engine still does not run smooth or releases a large amount of white smoke, loosen the fuel line nuts one at a time at the through the head adapters until the fuel that comes out is free of air. Tighten the fuel line nuts. If the air can not be removed in this way, put 35 kPa (5 psi) of air pressure to the fuel tank.

Do not use more than 55 kPa (8 psi) of air pressure in the fuel tank or damage to the tank may result.

Check for leakage at the connections between the fuel tank and the fuel transfer pump. If leaks are found, tighten the connections or replace the lines. It there are no visual leaks, remove the fuel supply line from the tank and connect it to an outside fuel supply. If this corrects the problem, the suction line (standpipe) inside the fuel tank has a leak. Low Quality FuelRemove a small amount of fuel from the tank and check for water in the fuel. If there is water in the fuel, remove fuel from the tank until it is free of water and fill with a good quality fuel. For more information see Special Instruction, Form No. SEHS7067, Fuel Recommendations For Caterpillar Diesel Engines.Change the fuel filter and "prime" (remove the air and/or low quality fuel from the fuel system) the fuel system with the fuel priming pump. If there is no water in the fuel, prime and start the engine by using an outside source of fuel. If engine starts correctly using different fuel, remove all fuel from the tank and fill with good quality fuel. Prime the fuel system if necessary. Low Fuel PressureChange the primary and secondary fuel filters and check to make sure the fuel lines are not plugged or damaged. If the filters or lines are not the cause, a repair or replacement of the fuel transfer pump is needed. Fuel Injection Timing Not CorrectCheck and make necessary adjustments as in Testing and Adjusting Section of this Service Manual. Valve Adjustment Not CorrectCheck and make necessary adjustments as in Testing and Adjusting Section of this Service Manual. Intake valve lash is 0.38 mm (.015 in) and exhaust valve lash is 0.64 mm (.025 in). Defective Fuel Nozzle(s)Remove the fuel nozzles and test as in Testing and Adjusting Section of this Service Manual. Low CompressionSee "Misfiring and Running Rough".Exhaust Smoke Cannot Be Seen While Starting

Possible Causes/Corrections

No Fuel In Tank(s)Check fuel level visually

It may be necessary to use starting aids, or to heat engine oil or coolant at temperatures below -12°C (10°F). Air In Fuel SystemWith air in the fuel system, the engine will normally be difficult to start, run rough, and release a large amount of white smoke. If the engine will not start, loosen a fuel injection line nut at the through the head adapter and crank the engine until fuel comes out. Tighten the fuel line nut. Start the engine. If the engine still does not run smooth or releases a large amount of white smoke, loosen the fuel line nuts one at a time at the through the head adapters until the fuel that comes out is free of air. Tighten the fuel line nuts. If the air can not be removed in this way, put 35 kPa (5 psi) of air pressure to the fuel tank.

Do not use more than 55 kPa (8 psi) of air pressure in the fuel tank or damage to the tank may result.

Check for leakage at the connections between the fuel tank and the fuel transfer pump. If leaks are found, tighten the connections or replace the lines. It there are no visual leaks, remove the fuel supply line from the tank and connect it to an outside fuel supply. If this corrects the problem, the suction line (standpipe) inside the fuel tank has a leak. Low Quality FuelRemove a small amount of fuel from the tank and check for water in the fuel. If there is water in the fuel, remove fuel from the tank until it is free of water and fill with a good quality fuel. For more information see Special Instruction, Form No. SEHS7067, Fuel Recommendations For Caterpillar Diesel Engines.Change the fuel filter and "prime" (remove the air and/or low quality fuel from the fuel system) the fuel system with the fuel priming pump. If there is no water in the fuel, prime and start the engine by using an outside source of fuel. If engine starts correctly using different fuel, remove all fuel from the tank and fill with good quality fuel. Prime the fuel system if necessary. Low Fuel PressureChange the primary and secondary fuel filters and check to make sure the fuel lines are not plugged or damaged. If the filters or lines are not the cause, a repair or replacement of the fuel transfer pump is needed. Fuel Injection Timing Not CorrectCheck and make necessary adjustments as in Testing and Adjusting Section of this Service Manual. Valve Adjustment Not CorrectCheck and make necessary adjustments as in Testing and Adjusting Section of this Service Manual. Intake valve lash is 0.38 mm (.015 in) and exhaust valve lash is 0.64 mm (.025 in). Defective Fuel Nozzle(s)Remove the fuel nozzles and test as in Testing and Adjusting Section of this Service Manual. Low CompressionSee "Misfiring and Running Rough".Exhaust Smoke Cannot Be Seen While Starting

Possible Causes/Corrections

No Fuel In Tank(s)Check fuel level visually