Rating:

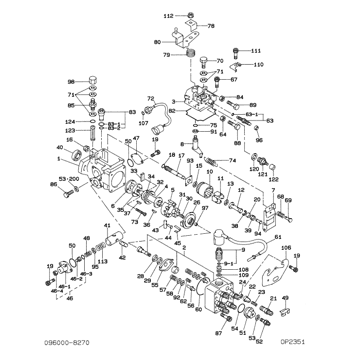

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

LAND CRUISER 1HZ

Engine

1HZ

Serial start-end

9208--9305

Info

Injector Nozzle

093500-3650

Manufacture:

22100-17450 TOYOTA

Dim 1

3.2-3.4

Dim 2

5.8-6.0

Dim 3

0.19-0.39

Dim 4

Dim 5

Dim 6

Information

Injector nozzle:

0935003650

KIT List:

Part name

Kit1

Kit2

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$1,007.93

18 Jun 2024

CN: GEMMOE

22100-17450 096000-8270 Diesel Fuel Injection Pump VE6/10F2000RND827

Thcbme Part Number: 096000-8270 VE6/10F2000RND827 22100-17450 || Diesel Fuel Injection VE Pump 096000-8270 VE6/10F2000RND827 22100-17450 || High efficiency: for a stable and efficient fuel supply || Ideal replacement: Precision engineered to match specific vehicles || Ensure fit: To make sure this part fits your exact vehicle

Thcbme Part Number: 096000-8270 VE6/10F2000RND827 22100-17450 || Diesel Fuel Injection VE Pump 096000-8270 VE6/10F2000RND827 22100-17450 || High efficiency: for a stable and efficient fuel supply || Ideal replacement: Precision engineered to match specific vehicles || Ensure fit: To make sure this part fits your exact vehicle

$1,250.30

18 Jun 2024

0.0022[0.00] Pounds

CN: meiyuanlei

Diesel Fuel Injection VE Pump 096000-8270 VE6/10F2000RND827 22100-17450

AKkis ☆ Diesel Fuel Injection VE Pump 096000-8270 VE6/10F2000RND827 22100-17450 || ☆ Quiet: The fuel pump is carefully designed and optimized, with low noise level, reducing noise interference during vehicle driving and improving driving experience and comfort. || ☆ High efficiency: The fuel pump can deliver fuel to the engine in a very short time to ensure the smooth operation and efficient combustion of the engine, thereby improving fuel utilization and vehicle performance. || ☆ Stability: Using advanced technology and design, it ensures stable fuel supply under various working conditions and prevents insufficient or excessive fuel reserve, thereby improving the driving safety and reliability of the car. || ☆ Energy saving and environmental protection: The fuel pump can intelligently adjust the amount of fuel supply according to the needs of the engine, avoid energy waste and excessive exhaust emissions, reduce environmental pollution, and improve fuel economy.

AKkis ☆ Diesel Fuel Injection VE Pump 096000-8270 VE6/10F2000RND827 22100-17450 || ☆ Quiet: The fuel pump is carefully designed and optimized, with low noise level, reducing noise interference during vehicle driving and improving driving experience and comfort. || ☆ High efficiency: The fuel pump can deliver fuel to the engine in a very short time to ensure the smooth operation and efficient combustion of the engine, thereby improving fuel utilization and vehicle performance. || ☆ Stability: Using advanced technology and design, it ensures stable fuel supply under various working conditions and prevents insufficient or excessive fuel reserve, thereby improving the driving safety and reliability of the car. || ☆ Energy saving and environmental protection: The fuel pump can intelligently adjust the amount of fuel supply according to the needs of the engine, avoid energy waste and excessive exhaust emissions, reduce environmental pollution, and improve fuel economy.

$1,013.93

18 Jun 2024

0.1366[0.06] Pounds

CN: ChengJiaHui Auto par

Diesel Fuel Injection VE Pump 096000-8270 VE6/10F2000RND827 22100-17450

TINYME OEM NO: 096000-8270 VE6/10F2000RND827 22100-17450 || Diesel Fuel Injection VE Pump 096000-8270 VE6/10F2000RND827 22100-17450 || ✍ With anti-clogging design, it can effectively filter impurities and particles in the oil to ensure that the fuel flows smoothly. This will extend the life of the fuel pump and reduce the frequency of maintenance. || ✍ A simple installation procedure also ensures that it will remain efficient over a long period of time, eliminating the need for frequent replacement. || ✍ We value the support of every customer, whether it's product selection, the buying process or after-sales support, we're always there for you.

TINYME OEM NO: 096000-8270 VE6/10F2000RND827 22100-17450 || Diesel Fuel Injection VE Pump 096000-8270 VE6/10F2000RND827 22100-17450 || ✍ With anti-clogging design, it can effectively filter impurities and particles in the oil to ensure that the fuel flows smoothly. This will extend the life of the fuel pump and reduce the frequency of maintenance. || ✍ A simple installation procedure also ensures that it will remain efficient over a long period of time, eliminating the need for frequent replacement. || ✍ We value the support of every customer, whether it's product selection, the buying process or after-sales support, we're always there for you.

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09600-08270

PUMP ASSY, INJECTI

22100-17450

TOYOTA

Include in ##:

09600-08270

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09600-08270

22100-1745

PUMP ASSY, INJECTI

0960008270

22100-17450

TOYOTA

PUMP ASSY, INJECTI

Information:

After Storage

Test the main stator windings with a megohmmeter in the following situations: 1. Before initial startup of generator set.2. Every 3 months* if generator is operating in a humid environment.3. If generator has not been run under load for 3 months* or more.*This is a guideline only. It may be necessary to megger more frequently if environment is extremely humid, salty or if the last megger test was close to 1 megohm.The megohmmeter test is described in Service Manuals SENR2180 or SENR7968. A reading of 1 meghom or less indicates that the winding has absorbed too much moisture.To Remove Moisture

To remove moisture caused by high humidity, use one of the following methods to make the generator dry:1. Energize space heaters in generator if so equipped.2. Put the generator in an oven at a temperature of not more than 85°C (185°F) for four hours.

If an oven is used for drying, use a forced air type rather than a radiant type. Radiant ovens can cause localized overheating.

3. Space heaters of the same type used in marine applications, can be installed on generators. (See the Parts Book.) These heaters heat the windings to remove moisture and should be connected at all times in high humidity conditions whenever the generator is not running.4. Use a canvas enclosure around the generator and heating lamps to increase the temperature. Make an opening in the top for release of moisture.5. Send a low voltage current through the windings to increase the temperature of the windings. Do not exceed 85°C (185°F).If the megohmmeter test reads under 1 megohm after the drying or if it goes below 1 megohm shortly after drying, contact your Caterpillar dealer. The insulation has deteriorated and should be reconditioned.

Test the main stator windings with a megohmmeter in the following situations: 1. Before initial startup of generator set.2. Every 3 months* if generator is operating in a humid environment.3. If generator has not been run under load for 3 months* or more.*This is a guideline only. It may be necessary to megger more frequently if environment is extremely humid, salty or if the last megger test was close to 1 megohm.The megohmmeter test is described in Service Manuals SENR2180 or SENR7968. A reading of 1 meghom or less indicates that the winding has absorbed too much moisture.To Remove Moisture

To remove moisture caused by high humidity, use one of the following methods to make the generator dry:1. Energize space heaters in generator if so equipped.2. Put the generator in an oven at a temperature of not more than 85°C (185°F) for four hours.

If an oven is used for drying, use a forced air type rather than a radiant type. Radiant ovens can cause localized overheating.

3. Space heaters of the same type used in marine applications, can be installed on generators. (See the Parts Book.) These heaters heat the windings to remove moisture and should be connected at all times in high humidity conditions whenever the generator is not running.4. Use a canvas enclosure around the generator and heating lamps to increase the temperature. Make an opening in the top for release of moisture.5. Send a low voltage current through the windings to increase the temperature of the windings. Do not exceed 85°C (185°F).If the megohmmeter test reads under 1 megohm after the drying or if it goes below 1 megohm shortly after drying, contact your Caterpillar dealer. The insulation has deteriorated and should be reconditioned.