Rating:

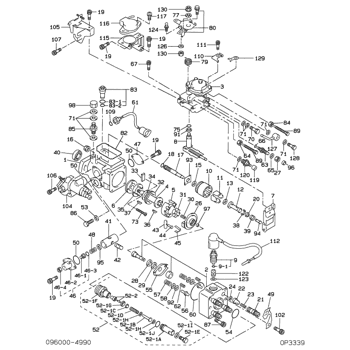

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

CRESSIDA 2L-T

Engine

2L-T

Serial start-end

8808--8902

Info

Injector Nozzle

093500-4190

Injector nozzle:

0935004190

KIT List:

Part name

Kit1

Kit2

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09600-04990

PUMP ASSY, INJECTI

Include in ##:

09600-04990

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09600-04990

PUMP ASSY, INJECTI

Information:

General Coolant Information

Several industry sources claim that forty percent of all engine failures are due to cooling system problems. Many of these failures could be avoided with proper cooling system maintenance. Cooling system maintenance is as important as fuel and lubricating system maintenance. Coolant quality is as important as the quality of fuel and lubricating oil.The three main coolant functions provide:* adequate heat transfer and anti-boil protection,* cavitation erosion and corrosion protection,* anti-freeze protection.Coolant is normally composed of three elements:* Water* Additives* GlycolA brief discussion of each of these elements follows.Water

Distilled or deionized water is recommended for use in cooling systems. DO NOT use hard, tap water or salt softened tap water in engine cooling systems. If Distilled or deionized water is NOT available, use water that meets the Minimum Acceptable requirements listed in the following chart.

ppm=parts per million

Water that does not meet the Minimum Acceptable limits will reduce engine service life when used in cooling systems.

If you are not sure of your water's contents, contact your Caterpillar dealer, your local water department, agricultural agent, or an independent laboratory to analyze the water.Additives

Additives must be included in all coolant mixtures. Additives help prevent the formation of rust, scale and mineral deposits. Additives protect metals from corrosion, prevent liner cavitation, and contain anti-foaming agents. Additives deplete during engine operation and need to be replenished. This is done through the addition of supplemental coolant additives (SCAs, with conventional coolants) or Extender (with Caterpillar

Several industry sources claim that forty percent of all engine failures are due to cooling system problems. Many of these failures could be avoided with proper cooling system maintenance. Cooling system maintenance is as important as fuel and lubricating system maintenance. Coolant quality is as important as the quality of fuel and lubricating oil.The three main coolant functions provide:* adequate heat transfer and anti-boil protection,* cavitation erosion and corrosion protection,* anti-freeze protection.Coolant is normally composed of three elements:* Water* Additives* GlycolA brief discussion of each of these elements follows.Water

Distilled or deionized water is recommended for use in cooling systems. DO NOT use hard, tap water or salt softened tap water in engine cooling systems. If Distilled or deionized water is NOT available, use water that meets the Minimum Acceptable requirements listed in the following chart.

ppm=parts per million

Water that does not meet the Minimum Acceptable limits will reduce engine service life when used in cooling systems.

If you are not sure of your water's contents, contact your Caterpillar dealer, your local water department, agricultural agent, or an independent laboratory to analyze the water.Additives

Additives must be included in all coolant mixtures. Additives help prevent the formation of rust, scale and mineral deposits. Additives protect metals from corrosion, prevent liner cavitation, and contain anti-foaming agents. Additives deplete during engine operation and need to be replenished. This is done through the addition of supplemental coolant additives (SCAs, with conventional coolants) or Extender (with Caterpillar