Rating:

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

DYNA 3L

Engine

3L

Serial start-end

8808-

Info

Injector Nozzle

093500-4180

Manufacture:

22100-54830 TOYOTA

Dim 1

3.2-3.4

Dim 2

5.4-5.6

Dim 3

0.3-0.5

Dim 4

Dim 5

Dim 6

Information

Injector nozzle:

0935004180

KIT List:

Part name

Kit1

Kit2

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

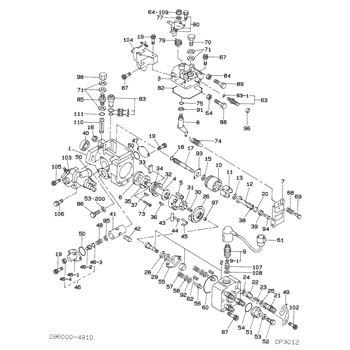

09600-04910

PUMP ASSY, INJECTI

WITHOUT TACHO

22100-54830

TOYOTA

Include in ##:

09600-04910

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09600-04910

22100-5483

PUMP ASSY, INJECTI

0960004910

22100-54830

TOYOTA

PUMP ASSY, INJECTI

Information:

Safety Section

Do not perform any procedure in this Special Instruction until you have read this Special Instruction and you understand this information. Use only proper tools and observe all precautions that pertain to the use of those tools. Failure to follow these procedures can result in personal injury. The following procedures should be observed.Work safely. Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs.A person must be alert to potential hazards. This person must also have the necessary training, skills, and tools to perform these functions properly.Safety precautions and warnings are provided in this instruction and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons. Caterpillar cannot anticipate every possible circumstance of a potential hazard.Therefore, the warnings in this publication and the warnings that are on the product are not all inclusive. Avoid using a tool, a procedure, a work method, or operating technique that is not recommended by Caterpillar.Ensure that the product will not be damaged or the product will be made unsafe by the operation, lubrication, maintenance, or the repair procedures.

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Failure to follow all safety guidelines prescribed in this document and by governing authorities and regulatory agencies may result in severe injury or death of personnel or machine damage.

Reset Procedure for DPF Soot Load

Perform the following procedure to reset DPF soot load:

Turn the generator set battery disconnect to ON position.

Verify power to Electronic Modular Control Panel (EMCP).

Connect Cat® Electronic Technician (Cat ET) service tool.

Connect to Cat ET - Configuration EMCP Controller.

Update "RO#2" on EMCP from "Eng Start Initiated" to "Auto Mode".

Change the generator set to auto mode. Changing the generator set to auto mode applies power to engine Electronic Control Module (ECM).

Verify whether the active code in Cat ET is "3719-0 - High DPF Soot Load".

Illustration 1 g06574660

Electronic Modular Control Panel

Illustration 2 g06574661

Engine Electronic Control Module

Check whether the parameters shown in Illustration 1 and Illustration 2 are set in "EMCP" and "Engine ECM" configurations.

Illustration 3 g06574662

Perform DPF soot load reset by navigating "Component Replacement Resets".

Verify DPF Soot Load value in "Engine Status" screen.

Verify the active codes.

Stop the unit in EMCP.

Update "RO#2" from "Auto Mode" to "Eng Start Initiated".

Check whether the unit is set to run at idle speed in "EMCP".

Run the unit and check whether "low idle speed" is 1200 rpm. Refer to Illustration 3.

Manually start the DPF regeneration.

Shut down the unit.

Do not perform any procedure in this Special Instruction until you have read this Special Instruction and you understand this information. Use only proper tools and observe all precautions that pertain to the use of those tools. Failure to follow these procedures can result in personal injury. The following procedures should be observed.Work safely. Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs.A person must be alert to potential hazards. This person must also have the necessary training, skills, and tools to perform these functions properly.Safety precautions and warnings are provided in this instruction and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons. Caterpillar cannot anticipate every possible circumstance of a potential hazard.Therefore, the warnings in this publication and the warnings that are on the product are not all inclusive. Avoid using a tool, a procedure, a work method, or operating technique that is not recommended by Caterpillar.Ensure that the product will not be damaged or the product will be made unsafe by the operation, lubrication, maintenance, or the repair procedures.

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Failure to follow all safety guidelines prescribed in this document and by governing authorities and regulatory agencies may result in severe injury or death of personnel or machine damage.

Reset Procedure for DPF Soot Load

Perform the following procedure to reset DPF soot load:

Turn the generator set battery disconnect to ON position.

Verify power to Electronic Modular Control Panel (EMCP).

Connect Cat® Electronic Technician (Cat ET) service tool.

Connect to Cat ET - Configuration EMCP Controller.

Update "RO#2" on EMCP from "Eng Start Initiated" to "Auto Mode".

Change the generator set to auto mode. Changing the generator set to auto mode applies power to engine Electronic Control Module (ECM).

Verify whether the active code in Cat ET is "3719-0 - High DPF Soot Load".

Illustration 1 g06574660

Electronic Modular Control Panel

Illustration 2 g06574661

Engine Electronic Control Module

Check whether the parameters shown in Illustration 1 and Illustration 2 are set in "EMCP" and "Engine ECM" configurations.

Illustration 3 g06574662

Perform DPF soot load reset by navigating "Component Replacement Resets".

Verify DPF Soot Load value in "Engine Status" screen.

Verify the active codes.

Stop the unit in EMCP.

Update "RO#2" from "Auto Mode" to "Eng Start Initiated".

Check whether the unit is set to run at idle speed in "EMCP".

Run the unit and check whether "low idle speed" is 1200 rpm. Refer to Illustration 3.

Manually start the DPF regeneration.

Shut down the unit.