Rating:

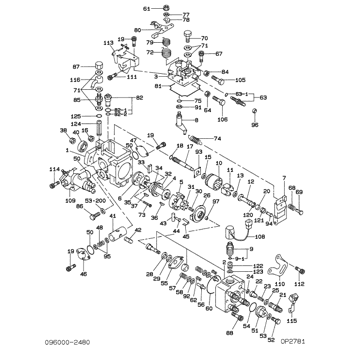

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

TOWNACE/LITEACE 1C

Engine

1C

Serial start-end

8508--8608

Info

Injector Nozzle

093500-3240

Manufacture:

22100-64840 TOYOTA

Dim 1

3.2-3.4

Dim 2

5.8-6.0

Dim 3

0.61-0.81

Dim 4

Dim 5

Dim 6

Information

Injector nozzle:

0935003240

KIT List:

Part name

Kit1

Kit2

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09600-02480

PUMP ASSY, INJECTI

22100-64840

TOYOTA

Include in ##:

09600-02480

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09600-02480

22100-6484

PUMP ASSY, INJECTI

0960002480

22100-64840

TOYOTA

PUMP ASSY, INJECTI

Information:

Table 1

M5X COMMUNICATION TROUBLESHOOTING

Problem Possible Explanation Action Required

CCM shows error codes E02 and E08 when receiving data from the PC and will not communicate. 1. There is a protocol error.

2. The data is not in ASCII format.

3. An incorrect checksum was sent.

4. Baud rate of the CCM and PC not matched. Correct the message being sent to the CCM

RS-232 receive lights are not lighted, and the CCM will not communicate with the PC even though no error codes are appearing. Hardware connection between the PC and CCM is corrupted or disconnected. Using the CCM PC software, connect to the CCM and determine if the connection to the PC is valid.

Cannot log into the CCM Connection problem exists or using the wrong M5X protocol for logging in. Use a read request (PID $F0 $12) to verify that the PC is available to communicate with the CCM. If a valid response is returned, proceed to log in as described in the Logging in section of this manual. If the password has been forgotten, call the CCM Help Desk.

Cannot get data from the electronic controller. 1. The electronic controller specified is not available.

2. The logged in security level is not high enough to support the request.

3. The electronic controller does not support the PID. 1. Verify that the electronic controller and the CCM are connected on the same data link.

2. Verify that the logged in security level is high enough to support the request.

3. Verify that the electronic controller supports the PID being requested.

Multiple responses are being generated from a single electronic controller Multiple electronic controllers have the same MID. Program the engine number of the electronic controller. Refer to the CCM/Data Link Guidelines section and Programming the Engine Number section in this manual.

An entire broadcast list is not returned. 1. The electronic controller specified is not available.

2. The electronic controller does not support any one of the PID's.

3. The PID contains greater than two bytes of data. Refer to the CCM Customized System section, IID 10 and IID 13 in this manual

A broadcast list update rate is too slow or inconsistent. 1. Too many parameters are being requested.

2. RS-232 baud rate is slow. 1. Verify that the RS-232 and modem baud rates are at least 9600 baud. CCM can not broadcast more than 40 parameters per second. Use IID 13, Byte 7 to slow the update rate for stable parameters such as hour meter, atmospheric pressure, temperature, diagnostics, etc. Use a faster rate for more dynamic parameters such as engine speed, oil pressure, etc. Refer to the RS-232 Communication Protocol for Customized Systems section in this manual for further information.

2. Increase the RS-232 baud rate.