Rating:

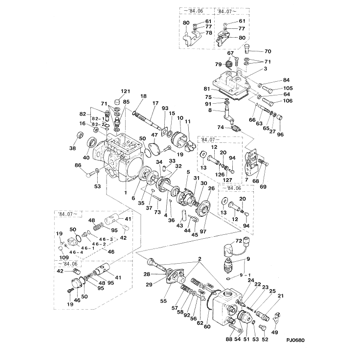

Information pump assy, injecti Denso

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09600-01462

PUMP ASSY, INJECTI

FOR 12V CAR

22100-54310

TOYOTA

Include in ##:

09600-01462

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09600-01462

22100-5431

PUMP ASSY, INJECTI

Information:

P-101: Engine Will Not Crank

Probable root causes:

These are NOT electronic problems with the 3176 Diesel Truck Engine* Batteries* Starting Circuit Problem (in vehicle wiring)* Starter Solenoid* Starter Motor* Starter Ring Gear* Transmission or Power Take-Off Problem* Hydraulic Cylinder Lock* Internal Engine ProblemPerform the following tests in order: For details of the following tests, refer to 3176 Diesel Truck Engine, Form No. SENR4248, for Mechanical Troubleshooting.1. Charge batteries (see Special Instruction, Form No. SEHS7633, for Battery Test Procedure).2. Load test batteries (see Operating Manual, Form No. SEHS9249, for Use Of 4C4911 Battery Load Tester.3. Check vehicle wiring to starter solenoid (see vehicle manufacturers instructions).4. Inspect starter cables for damage or loose connections.5. Remove and clean starter cables and connections if corroded.6. Test starter solenoid operation. Refer to 3176 Diesel Truck Engine, Form No. SENR3909, for Systems Operation Testing and Adjusting.7. Test starter motor operation. Refer to 3176 Diesel Truck Engine, Form No. SENR3909, for Systems Operation Testing and Adjusting.8. Remove and inspect starter ring gear for damage.9. If engine will not turn over by hand, disconnect transmission and check for damage.10. Check for fluid in cylinders by removing individual nozzles.11. Disassemble engine to inspect for internal components that may be seized, broken, out of alignment, etc. Refer to 3176 Diesel Truck Engine, Form No. SENR3914, for Disassembly & Assembly.P-102: Engine Cranks But Will Not Start

Probable root causes:

* Electrical power supply to the ECM.* Electrical connections to the fuel injectors.* Fuel supply* Engine Speed/Timing Signal* ECM or Personality Module failure.* Combustion problemPerform the following tests in order:1. P-210: Electrical Power Supply Test.2. If ECAP/DDT does not communicate with ECM, refer to P-120: ECAP/DDT Will Not Communicate With 3176 System, in this manual.3. Check that Fuel Injector Connector (J5/P5) is installed and oriented correctly.4. Check Fuel Pressure. Also, check that fuel system is primed and that fuel supply and return lines are not restricted. In temperatures below 0° C (32° F), check for congealed fuel (wax).5. P-221: Engine Speed/Timing Signal Test. Also be sure the timing reference ring is installed correctly (if the ring was installed backward during reassembly, the engine will not start).6. Check for combustion problems (too cold or mechanical problem).P-103: Engine Misfires, Runs Rough Or Is Unstable

If the problem is intermittent and cannot be recreated, refer to P-111: Intermittent Low Power Or Power Cutouts.If the problem is consistent and can be re-created, continue with this procedure.Probable root causes:

If the problem only occurs under certain conditions (high rpm, full load, etc.) test the engine under those conditions. Troubleshooting the symptoms under other conditions can give misleading results.* Three cylinder cutout* Individual cylinder malfunction* Throttle position signal* Fuel supply- high pressure- low pressure- air in fuel- poor quality fuel* Air inlet restriction* Exhaust restrictionPerform the following tests in order:1. Verify that the complaint is not about the normal operation of the three-cylinder cutout feature.2. Isolate misfiring cylinder(s). Refer to P-222: Isolating Misfiring Cylinders, in this manual.3. Check throttle linkage adjustment. Refer to P-303: Throttle Position Sensor Adjustment, in this manual.4.

Probable root causes:

These are NOT electronic problems with the 3176 Diesel Truck Engine* Batteries* Starting Circuit Problem (in vehicle wiring)* Starter Solenoid* Starter Motor* Starter Ring Gear* Transmission or Power Take-Off Problem* Hydraulic Cylinder Lock* Internal Engine ProblemPerform the following tests in order: For details of the following tests, refer to 3176 Diesel Truck Engine, Form No. SENR4248, for Mechanical Troubleshooting.1. Charge batteries (see Special Instruction, Form No. SEHS7633, for Battery Test Procedure).2. Load test batteries (see Operating Manual, Form No. SEHS9249, for Use Of 4C4911 Battery Load Tester.3. Check vehicle wiring to starter solenoid (see vehicle manufacturers instructions).4. Inspect starter cables for damage or loose connections.5. Remove and clean starter cables and connections if corroded.6. Test starter solenoid operation. Refer to 3176 Diesel Truck Engine, Form No. SENR3909, for Systems Operation Testing and Adjusting.7. Test starter motor operation. Refer to 3176 Diesel Truck Engine, Form No. SENR3909, for Systems Operation Testing and Adjusting.8. Remove and inspect starter ring gear for damage.9. If engine will not turn over by hand, disconnect transmission and check for damage.10. Check for fluid in cylinders by removing individual nozzles.11. Disassemble engine to inspect for internal components that may be seized, broken, out of alignment, etc. Refer to 3176 Diesel Truck Engine, Form No. SENR3914, for Disassembly & Assembly.P-102: Engine Cranks But Will Not Start

Probable root causes:

* Electrical power supply to the ECM.* Electrical connections to the fuel injectors.* Fuel supply* Engine Speed/Timing Signal* ECM or Personality Module failure.* Combustion problemPerform the following tests in order:1. P-210: Electrical Power Supply Test.2. If ECAP/DDT does not communicate with ECM, refer to P-120: ECAP/DDT Will Not Communicate With 3176 System, in this manual.3. Check that Fuel Injector Connector (J5/P5) is installed and oriented correctly.4. Check Fuel Pressure. Also, check that fuel system is primed and that fuel supply and return lines are not restricted. In temperatures below 0° C (32° F), check for congealed fuel (wax).5. P-221: Engine Speed/Timing Signal Test. Also be sure the timing reference ring is installed correctly (if the ring was installed backward during reassembly, the engine will not start).6. Check for combustion problems (too cold or mechanical problem).P-103: Engine Misfires, Runs Rough Or Is Unstable

If the problem is intermittent and cannot be recreated, refer to P-111: Intermittent Low Power Or Power Cutouts.If the problem is consistent and can be re-created, continue with this procedure.Probable root causes:

If the problem only occurs under certain conditions (high rpm, full load, etc.) test the engine under those conditions. Troubleshooting the symptoms under other conditions can give misleading results.* Three cylinder cutout* Individual cylinder malfunction* Throttle position signal* Fuel supply- high pressure- low pressure- air in fuel- poor quality fuel* Air inlet restriction* Exhaust restrictionPerform the following tests in order:1. Verify that the complaint is not about the normal operation of the three-cylinder cutout feature.2. Isolate misfiring cylinder(s). Refer to P-222: Isolating Misfiring Cylinders, in this manual.3. Check throttle linkage adjustment. Refer to P-303: Throttle Position Sensor Adjustment, in this manual.4.