Rating:

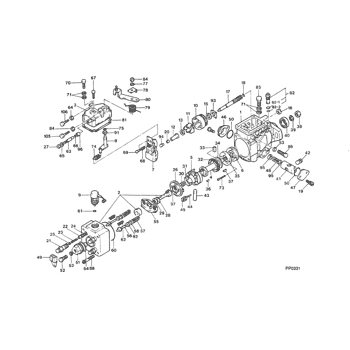

Information pump assy, injecti Denso

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09600-00431

PUMP ASSY, INJECTI

22100-54060

TOYOTA

Include in ##:

09600-00431

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09600-00431

22100-5406

PUMP ASSY, INJECTI

Information:

Maintenance Intervals

The Maintenance Schedule requires all previous interval maintenance items to be performed first. For instance, if the Every 250 Hour maintenance is being done, then the Daily and Every 250 Hour maintenance items must be completed BEFORE performing the Every 1000 Hour maintenance.Engines may be equipped with various optional components and the Schedule may recommend maintenance for items not installed on your engine. Simply disregard reference to any extraneous items. If unsure of any item, consult your Caterpillar dealer.Overhaul Interval

One interval for some engines is labeled Top End because it involves removal, inspection, and rework of the cylinder head components. This interval is dependent on load-sensitive items/total amount of fuel consumed.The last interval in each chart lists the components inspected, rebuilt, exchanged or replaced at overhaul. Overhaul is defined as the interval at which the major wear items in the engine should be replaced. The intervals represent maintenance of a non-failed engine. In other words, the engine is being rebuilt with certain new parts replacing worn parts such as piston rings, engine rod and main bearings, valves and valve seats., etc.Incidental to the replacement of these relatively few parts is the complete inspection of all other parts that are visible during the overhaul of the engine. The disassembly required to do an overhaul means that disturbed seals and gaskets, etc., will be replaced, and the internal passages of the engine and block be cleaned.* The Overhaul interval assumes that regular maintenance recommendations in the rest of the chart have been carefully followed.* Some users may obtain significantly longer or shorter life than the chart recommends between overhauls, but if the recommended intervals are followed, OVERHAULS will occur BEFORE actual FAILURE, and the total COST of operation will be minimized.Although most users will obtain more life between overhauls than the chart recommends, Caterpillar has determined that these limits are the best (least cost) for the vast majority of our engine users. Extend the intervals to overhaul ONLY if your experience shows strong evidence that the intervals are too short for your application and maintenance practices.The most important criteria for Top End and Overhaul is Fuel Consumption. The hours criteria is mainly for reference.Interval Terminology

Engine components can generally be grouped into speed sensitive and load sensitive categories. Therefore, the maintenance interval for each item listed in the Maintenance Schedule is primarily based on the item and its relationship to either engine speed or load. Speed sensitive items such as water pumps, alternators, air compressors, etc., are not primarily affected by the load on your engine during operation. The load on an engine will not significantly accelerate the repair or replacement cycle for speed sensitive items. Therefore, the maintenance intervals established for speed sensitive items are based on calendar time and service hours. Load sensitive items such as piston rings, cylinder liners, bearings, etc., are affected by the load on your engine during operation. Generally speaking, the lower

The Maintenance Schedule requires all previous interval maintenance items to be performed first. For instance, if the Every 250 Hour maintenance is being done, then the Daily and Every 250 Hour maintenance items must be completed BEFORE performing the Every 1000 Hour maintenance.Engines may be equipped with various optional components and the Schedule may recommend maintenance for items not installed on your engine. Simply disregard reference to any extraneous items. If unsure of any item, consult your Caterpillar dealer.Overhaul Interval

One interval for some engines is labeled Top End because it involves removal, inspection, and rework of the cylinder head components. This interval is dependent on load-sensitive items/total amount of fuel consumed.The last interval in each chart lists the components inspected, rebuilt, exchanged or replaced at overhaul. Overhaul is defined as the interval at which the major wear items in the engine should be replaced. The intervals represent maintenance of a non-failed engine. In other words, the engine is being rebuilt with certain new parts replacing worn parts such as piston rings, engine rod and main bearings, valves and valve seats., etc.Incidental to the replacement of these relatively few parts is the complete inspection of all other parts that are visible during the overhaul of the engine. The disassembly required to do an overhaul means that disturbed seals and gaskets, etc., will be replaced, and the internal passages of the engine and block be cleaned.* The Overhaul interval assumes that regular maintenance recommendations in the rest of the chart have been carefully followed.* Some users may obtain significantly longer or shorter life than the chart recommends between overhauls, but if the recommended intervals are followed, OVERHAULS will occur BEFORE actual FAILURE, and the total COST of operation will be minimized.Although most users will obtain more life between overhauls than the chart recommends, Caterpillar has determined that these limits are the best (least cost) for the vast majority of our engine users. Extend the intervals to overhaul ONLY if your experience shows strong evidence that the intervals are too short for your application and maintenance practices.The most important criteria for Top End and Overhaul is Fuel Consumption. The hours criteria is mainly for reference.Interval Terminology

Engine components can generally be grouped into speed sensitive and load sensitive categories. Therefore, the maintenance interval for each item listed in the Maintenance Schedule is primarily based on the item and its relationship to either engine speed or load. Speed sensitive items such as water pumps, alternators, air compressors, etc., are not primarily affected by the load on your engine during operation. The load on an engine will not significantly accelerate the repair or replacement cycle for speed sensitive items. Therefore, the maintenance intervals established for speed sensitive items are based on calendar time and service hours. Load sensitive items such as piston rings, cylinder liners, bearings, etc., are affected by the load on your engine during operation. Generally speaking, the lower