Rating:

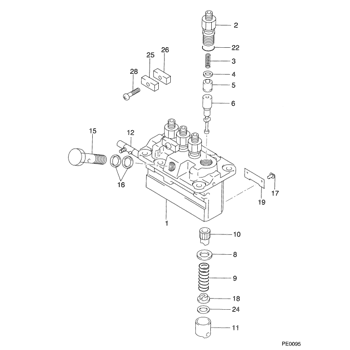

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

TRACTOR V3800DI-E

Engine

V3800DI-E

Serial start-end

0307-

Info

Injector Nozzle

093500-7810

KUBOTA

PUMP ASSY, INJECTI

MA

- NOZZLE & NOZZLE HOLDER:093500-7810(E/G:V3800DI-E),

- 093500-7870(V3800DI-TE),093500-7880(V3800DI-TIE).

Injector nozzle:

0935007810

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

IMIFAFTAbT Fuel Injection Pump 094500-8190 0945008190 for Bobcat Skid Steer Loader S220 S250 S300 T250 T300 for Kubota Engine V3300 V3600 V3800 Tractor M8540DT M9540 M9540HD12 M105XDTC M105SDT

IMIFAFTAbT Part Name:Fuel Injection Pump 094500-8190 0945008190 || Part Number:094500-8190 0945008190 || APPlication: Compatible with Kubota V3300 V3600 V3800 Engine M8540DT M9540 M9540HD12 M105XDTC M105SDT Tractor for Bobcat S220 S250 S300 T250 T300 Skid Steer Loader || If you are not sure if the product is suitable please leave us a message and send us your original || product picture and part number and we will send the correct part after confirmation

IMIFAFTAbT Part Name:Fuel Injection Pump 094500-8190 0945008190 || Part Number:094500-8190 0945008190 || APPlication: Compatible with Kubota V3300 V3600 V3800 Engine M8540DT M9540 M9540HD12 M105XDTC M105SDT Tractor for Bobcat S220 S250 S300 T250 T300 Skid Steer Loader || If you are not sure if the product is suitable please leave us a message and send us your original || product picture and part number and we will send the correct part after confirmation

0945008190 Fuel Injection Pump for Kubota V3300 V3600 V3800 Engine M8540DT M9540 M9540HD12 M105XDTC M105SDT Tractor Bobcat S220 S250 S300 T250 T300 Skid Steer Loader

KoovDem Part Number: 094500-8190, 0945008190 || Engine Model: for Kubota Engine V3300, V3600, V3800, V3300DI, V3800DI, V3800-DI-T-E2B-AUSA-1, V3300DI-E2B-AEBI-2 || Compatible Models: for Kubota Tractor M8540DH, M8540DHC, M8540DT, M8540DTC, M8540F, M8540FC, M8540HD, M8540HD12, M8540HDC, M8540HDC12, M8540HDNB, M9540DH, M9540DHC, M9540DT, M9540DTC, M9540F, M9540FC, M9540HD, M9540HD12, M9540HDC, M9540HDC12, M9540HDC-LTD, M9540HDL, M9540HFL. These models are compatible with various Kubota tractors, offering a wide range of options for different agricultural needs. || Compatible models include Kubota Tractor M105S-CAB, M105SDS, M105SDSF, M105SDSL, M105SDT-CAB, M105SDT-CAB-CAN, M105SH, M105SHD, M105XDTC, M108SDC, M95SDS, M95SDT-CAB, M95SDT-CAB-CAN, M95SH, M95XDTC, M96SDS, M96SDSC, M96SH. || Compatible models include the Kubota Excavator KX080-3 and the Hyundai Skid Steer Loaders HSL850-7 and HSL800-7. These machines are specifically designed to work seamlessly with these equipment, ensuring optimal performance and efficiency. Whether for digging or loading tasks, these models are reliable and efficient choices for construction and landscaping projects.

KoovDem Part Number: 094500-8190, 0945008190 || Engine Model: for Kubota Engine V3300, V3600, V3800, V3300DI, V3800DI, V3800-DI-T-E2B-AUSA-1, V3300DI-E2B-AEBI-2 || Compatible Models: for Kubota Tractor M8540DH, M8540DHC, M8540DT, M8540DTC, M8540F, M8540FC, M8540HD, M8540HD12, M8540HDC, M8540HDC12, M8540HDNB, M9540DH, M9540DHC, M9540DT, M9540DTC, M9540F, M9540FC, M9540HD, M9540HD12, M9540HDC, M9540HDC12, M9540HDC-LTD, M9540HDL, M9540HFL. These models are compatible with various Kubota tractors, offering a wide range of options for different agricultural needs. || Compatible models include Kubota Tractor M105S-CAB, M105SDS, M105SDSF, M105SDSL, M105SDT-CAB, M105SDT-CAB-CAN, M105SH, M105SHD, M105XDTC, M108SDC, M95SDS, M95SDT-CAB, M95SDT-CAB-CAN, M95SH, M95XDTC, M96SDS, M96SDSC, M96SH. || Compatible models include the Kubota Excavator KX080-3 and the Hyundai Skid Steer Loaders HSL850-7 and HSL800-7. These machines are specifically designed to work seamlessly with these equipment, ensuring optimal performance and efficiency. Whether for digging or loading tasks, these models are reliable and efficient choices for construction and landscaping projects.

Fuel Injection Pump for Kubota V3300 V3600 V3800 Engine M8540DT M9540 M9540HD12 M105XDTC M105SDT Tractor Bobcat S220 S250 S300 T250 T300 Skid Steer Loader 094500-8190

KoovDem Part Number: 094500-8190 0945008190 094500-8191 || Vehicle Application:For Kubota Tractor M9540 M9540HD12 M8540DT M105XDTC M105SDT M105 M108; for Bobcat Skid Steer Loader S220 S250 S300 T250 T300 AL440 || We are committed to helping you find the right pump for your vehicle to ensure optimal performance. Regular maintenance and inspection can extend the pump's lifespan and prevent breakdowns. Follow manufacturer guidelines for installation and usage. Contact us for any queries or assistance. Thank you for choosing our products. || Service: We offer a 6-month warranty and 24-hour customer support for all products. If you have any questions or concerns, please don't hesitate to reach out to us via email.

KoovDem Part Number: 094500-8190 0945008190 094500-8191 || Vehicle Application:For Kubota Tractor M9540 M9540HD12 M8540DT M105XDTC M105SDT M105 M108; for Bobcat Skid Steer Loader S220 S250 S300 T250 T300 AL440 || We are committed to helping you find the right pump for your vehicle to ensure optimal performance. Regular maintenance and inspection can extend the pump's lifespan and prevent breakdowns. Follow manufacturer guidelines for installation and usage. Contact us for any queries or assistance. Thank you for choosing our products. || Service: We offer a 6-month warranty and 24-hour customer support for all products. If you have any questions or concerns, please don't hesitate to reach out to us via email.

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09450-08190

PUMP ASSY, INJECTI

PFR4A

-0309

1G514-51011

KUBOTA

000

[01]

09450-08190

PUMP ASSY, INJECTI

PFR4A

0309-

1G514-51012

KUBOTA

Include in ##:

09450-08190

as PUMP ASSY, INJECTI

09450-08190 PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09450-08190

1G514-5101

KUBOTA

PUMP ASSY, INJECTI

0945008190

1G514-51011

KUBOTA

PUMP ASSY, INJECTI

0945008190

1G514-51012

KUBOTA

PUMP ASSY, INJECTI

Information:

start by:a) remove turbocharger 1. Put the turbocharger in position on tool (A).2. Put a mark on the compressor cover and housings for installation purpose.3. Remove bolts (1) and plates from compressor housing.4. Remove the compressor housing. 5. Remove bolts (2) and locks from turbine housing. 6. Remove cartridge (3) from turbine housing.7. Install tool (B) in tool (C). Install cartridge in tool (C).8. Remove nut (4) from the compressor wheel.

When the nut is loosened, do not put a side force on the shaft.

9. Install tool (D) on an oil heater. Heat the oil to 350°F (177°C). Install the cartridge on tool (D) with only the compressor wheel in the hot oil. Keep the compressor wheel in the hot oil for ten minutes. 10. Put tool (D) and cartridge on tool (E) under a press. Install driver (F) and push the shaft out of the compressor wheel. Step 10 must be done before the compressor wheel gets cold.11. Remove compressor wheel and shroud. Remove turbine wheel and shaft. 12. Remove the four bolts (5) and locks from plate (6). 13. Remove plate (6), spacer, collar and thrust bearing from cartridge.14. Remove seal from plate and ring from spacer. 15. Remove bearing (7), washer (11) and snap ring (8) from compressor side of cartridge.16. Remove snap ring (13), washer (10), bearing (12) and snap ring (9) from turbine side of cartridge.17. Check all the parts of the turbocharger for damage. If the parts have damage, use new parts for replacement. See SPECIAL INSTRUCTION, Form No. SMHS6854 for TURBOCHARGER RECONDITIONING. Also see GUIDELINE FOR REUSABLE PARTS, Form No. SEBF8018.Assemble Turbocharger (Airesearch T18)

1. Make sure all oil passages are open and clean. Put clean engine oil on all parts before assembly 2. Install snap ring (6), bearing (3), washer (7) and snap ring (4) in turbine side of cartridge. Install the two snap rings with tool (A). Install the snap rings with the rounded edge toward the bearing.3. Install snap ring (2), washer (5) and bearing (1) in compressor side of cartridge. 4. Install seal (12) on plate (8) and ring (9) on spacer.5. Install collar (10) in plate and spacer (11) in collar. 6. Install thrust bearing (13) with the three radial grooves toward the outside.7. Install plate (8), bolts and locks. Tighten bolts to a torque of 35 5 lb. in. (4.0 0.6 N m). Put 6V2055 High Vacuum Grease in the groove for seal ring (14) at assembly to one half or more of the depth of the groove all the way around.8. Install ring (14) on turbine wheel.9. Install turbine wheel and shaft in cartridge. Be careful not to break ring (14) when installing shaft. 10. Put cartridge on tool (C) and tool (C) on tool (B). Some compressor wheels (15) can be installed at room temperature. If the compressor wheel will go on the turbine shaft freely to within .31 in. (7.9 mm) of the seal carrier the compressor wheel can be installed at

When the nut is loosened, do not put a side force on the shaft.

9. Install tool (D) on an oil heater. Heat the oil to 350°F (177°C). Install the cartridge on tool (D) with only the compressor wheel in the hot oil. Keep the compressor wheel in the hot oil for ten minutes. 10. Put tool (D) and cartridge on tool (E) under a press. Install driver (F) and push the shaft out of the compressor wheel. Step 10 must be done before the compressor wheel gets cold.11. Remove compressor wheel and shroud. Remove turbine wheel and shaft. 12. Remove the four bolts (5) and locks from plate (6). 13. Remove plate (6), spacer, collar and thrust bearing from cartridge.14. Remove seal from plate and ring from spacer. 15. Remove bearing (7), washer (11) and snap ring (8) from compressor side of cartridge.16. Remove snap ring (13), washer (10), bearing (12) and snap ring (9) from turbine side of cartridge.17. Check all the parts of the turbocharger for damage. If the parts have damage, use new parts for replacement. See SPECIAL INSTRUCTION, Form No. SMHS6854 for TURBOCHARGER RECONDITIONING. Also see GUIDELINE FOR REUSABLE PARTS, Form No. SEBF8018.Assemble Turbocharger (Airesearch T18)

1. Make sure all oil passages are open and clean. Put clean engine oil on all parts before assembly 2. Install snap ring (6), bearing (3), washer (7) and snap ring (4) in turbine side of cartridge. Install the two snap rings with tool (A). Install the snap rings with the rounded edge toward the bearing.3. Install snap ring (2), washer (5) and bearing (1) in compressor side of cartridge. 4. Install seal (12) on plate (8) and ring (9) on spacer.5. Install collar (10) in plate and spacer (11) in collar. 6. Install thrust bearing (13) with the three radial grooves toward the outside.7. Install plate (8), bolts and locks. Tighten bolts to a torque of 35 5 lb. in. (4.0 0.6 N m). Put 6V2055 High Vacuum Grease in the groove for seal ring (14) at assembly to one half or more of the depth of the groove all the way around.8. Install ring (14) on turbine wheel.9. Install turbine wheel and shaft in cartridge. Be careful not to break ring (14) when installing shaft. 10. Put cartridge on tool (C) and tool (C) on tool (B). Some compressor wheels (15) can be installed at room temperature. If the compressor wheel will go on the turbine shaft freely to within .31 in. (7.9 mm) of the seal carrier the compressor wheel can be installed at