Rating:

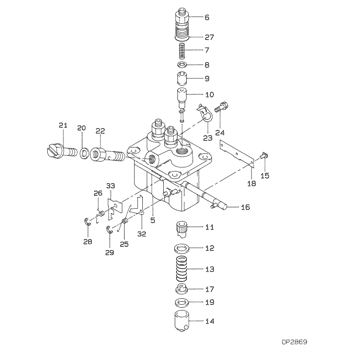

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

Construction machine K3E-61FT

Engine

K3E-61FT

Serial start-end

8709--9007

Info

Injector Nozzle

093500-1660

Injector nozzle:

0935001660

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

09450-04440

PUMP ASSY, INJECTI

Information:

Table 1

Crude Oil Specification for Cat 3600 and C280 Series Diesel Engines

Specifications Requirements ASTM Test ISO Test

Aromatics 35% maximum "D1319" "ISO 3837"

Ash 0.1% maximum (weight) "D482" "ISO 6245"

Carbon residue on 10% bottoms 3.5% maximum (weight) "D524" "ISO 4262"

Cetane number 40 minimum(1) "D613"

or

"D6890" "ISO 5165"

Cloud point The maximum cloud point must not exceed the lowest expected ambient temperature. - -

Copper strip corrosion No. 3 maximum "D130" "ISO 2160"

Distillation 10% at 282 °C (540 °F) maximum "D86" "ISO 3405"

90% at 380 °C (716 °F) maximum

minimum of 60% cracking

10% maximum residue

Reid Vapor pressure 138 kPa (20 psi) maximum "D323" "ISO 3007"

Salt 45.6 kg per 159 kL (100 lb per 1000 bbl) maximum "D3230" -

Flash point legal limit "D93" "ISO 2719"

API gravity 30 minimum

45 maximum "D287" -

Specific gravity(2) 0.8762 minimum

0.8017 maximum (2) (2)

Lighter fractions(3) 30% maximum - -

Fraction of kerosene and distillate (4) 30% minimum - -

Pour point 6 °C (10 °F) minimum below ambient temperature "D97" "ISO 3016"

Sulfur (5) (5) "D2622"

or

"D5453" "ISO 20846"

or

"ISO 20884"

Viscosity (6) 1.4 cSt minimum and 20.0 cSt maximum as delivered to the fuel injection pumps (6) (6)

Water and sediment 0.5% maximum (volume) "D1796" "ISO 3734"

Vanadium 4 ppm maximum "D5185-02" -

Sodium 10 ppm maximum "D5185-02" -

Nickel 1 ppm maximum "D5185-02" -

Aluminum 1 ppm maximum "D5185-02" -

Silicon 1 ppm maximum "D5185-02" -

Gums and resins(7) 10 mg per 100 mL (5.8 grains/US gal) maximum "D381" "ISO 6246"

Lubricity(8) 0.52 mm (0.0205 inch) maximum at 60 °C (140 °F) "D6079" -

(1) A fuel with a higher cetane number may be required for operation at a higher altitude or in cold weather.

(2) The specific gravity limits are determined by the standards tables using the "ASTM D287" test method temperature of 15.56 °C (60 °F). Also by the standards tables, the equivalent kg/m3 (kilograms per cubic meter) using the "ASTM D287" test method temperature of 15.56 °C (60 °F) for the minimum gravity of 30 is 875.7 kg/m3, and for the maximum API gravity of 45 is 801.3 kg/m3.

(3) Fractions that are boiled off at temperatures below 200 °C (392 °F)

(4) Fractions that are boiled off at temperatures between 200 °C (392 °F) and the cracking point.

(5) Sulfur in the fuel should be per the International Maritime Organization (IMO) regulations or as specified by the applicable jurisdiction. Refer to the specific engineOperation and Maintenance Manual to determine the maximum level of sulfur permissible where allowed by the applicable jurisdiction. Fuel sulfur levels affect exhaust emissions. High sulfur fuels increase the potential for corrosion of internal components. Fuel sulfur levels above 1% may significantly shorten the oil change interval. Caterpillar strongly recommends that S O S Services oil analysis is used to determine oil change intervals when the fuel sulfur levels are above 1%. For additional information, see this Special Publication, Engine Oil and Special Publication, SoOoS Services Oil Analysis topic. When the sulfur levels are above1%, consult your Cat dealer for guidance.

(6) The values of the fuel viscosity are the values as the fuel is delivered to the fuel injection pumps. For ease of comparison,