Rating:

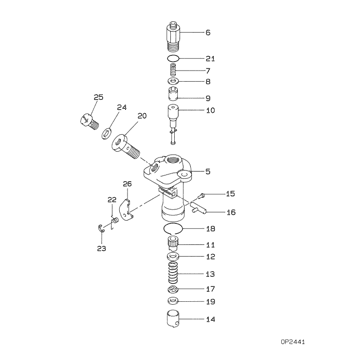

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL D75-21F

Engine

D75-21F

Serial start-end

8401--9011

Info

Injector Nozzle

093500-2350

Injector nozzle:

0935002350

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

09450-03120

PUMP ASSY, INJECTI

Information:

System Operation

A thermocouple is a temperature sensor. The thermocouple consists of two different metals. The metals are joined together at one end. A small voltage is produced when the junction is heated. The change in voltage is interpreted by an electronic device in order to determine a change in temperature. The MMS uses K type thermocouples. The K type thermocouples have ranges from -200 °C (-328 °F)to 1260 °C (2300 °F). This temperature range corresponds to a voltage range of negative 5.9 mV to 51.0 mV.The signal is used in order to trigger alarms and the signal is used in order to display the parameter.

Illustration 1 g00563634

Diagram of the thermocouple

Illustration 2 g00563637

Schematic of the thermocoupleFunctional Test

Check the electrical connectors and check the wiring.

Bodily contact with electrical potential can cause bodily injury or death.To avoid the possibility of injury or death, ensure that the main power supply has been disconnected before performing any maintenance or removing any modules.

Disconnect the power supply.

Check the electrical connectors and check the wiring for damage or bad connections.

Verify that all modules are properly seated.

Verify the status of the LED on the SLC 5/04.The results of the preceding procedure are in the following list:

All of the components are fully installed. All of the components are free of corrosion. All of the components are free of damage. All of the modules are properly seated. Stop.

The components are not fully installed. The components are not free of corrosion. The components are damaged. All of the modules are not properly seated. Repair the component. Verify that the repair resolves the problem. STOP.

A thermocouple is a temperature sensor. The thermocouple consists of two different metals. The metals are joined together at one end. A small voltage is produced when the junction is heated. The change in voltage is interpreted by an electronic device in order to determine a change in temperature. The MMS uses K type thermocouples. The K type thermocouples have ranges from -200 °C (-328 °F)to 1260 °C (2300 °F). This temperature range corresponds to a voltage range of negative 5.9 mV to 51.0 mV.The signal is used in order to trigger alarms and the signal is used in order to display the parameter.

Illustration 1 g00563634

Diagram of the thermocouple

Illustration 2 g00563637

Schematic of the thermocoupleFunctional Test

Check the electrical connectors and check the wiring.

Bodily contact with electrical potential can cause bodily injury or death.To avoid the possibility of injury or death, ensure that the main power supply has been disconnected before performing any maintenance or removing any modules.

Disconnect the power supply.

Check the electrical connectors and check the wiring for damage or bad connections.

Verify that all modules are properly seated.

Verify the status of the LED on the SLC 5/04.The results of the preceding procedure are in the following list:

All of the components are fully installed. All of the components are free of corrosion. All of the components are free of damage. All of the modules are properly seated. Stop.

The components are not fully installed. The components are not free of corrosion. The components are damaged. All of the modules are not properly seated. Repair the component. Verify that the repair resolves the problem. STOP.