Rating:

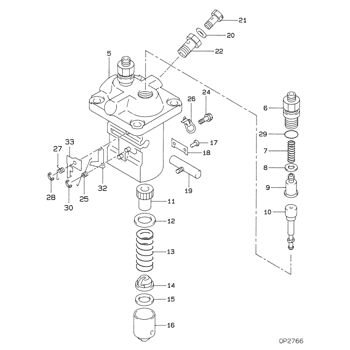

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

Construction machine KE70

Engine

KE70

Serial start-end

8401--9001

Info

Injector Nozzle

093500-1660

Injector nozzle:

0935001660

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09450-03000

PUMP ASSY, INJECTI

PFR2M

Include in ##:

09450-03000

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09450-03000

PUMP ASSY, INJECTI

Information:

Commercial Extended Life Coolant

Cat does not warrant the quality or performance of non-Cat fluids.

Inorder to be used in Cat diesel engine cooling systems at the published service intervals, select a commercial extended life coolant that meets all the requirements given in Table 1 in this Special Publication.

Table 1

Technical Requirements for Commercial Extended Life Coolants

Specifications Cat EC-1 and "ASTM D6210"

Additional Requirements Organic Additive Technology (OAT) based on a combination of a monocarboxylic acid and a dicarboxylic acid

Phosphate, borate, and silicate free

Minimum typical tolyltriazole level of 900 ppm for new coolants

Minimum typical nitrite level of 500 ppm in new coolants"

Maintenance One time addition of an extender at the mid-life of the coolant in order to maintain the coolant nitrite level between 300 - 600 ppm Note: The Cat EC-1 specification describes the minimum requirements for extended life coolants.Use an extender that is recommended by the EC-1 coolant supplier at mid-life of the coolant.Commercial coolants that do not meet the minimum requirements defined in this Special Publication are not allowed for use in Cat engines.Commercial extended life coolant used in Cat engines must meet all requirements given in Table 1. If the ELC does meet the requirements, the service interval listed in this Special Publication may not be used. Follow the maintenance guidelines for the coolant from the supplier of the commercial extended life coolant. Follow the Cat guidelines for the quality of water and the specified coolant change interval.Note: Coolants must be tested against the Cat EC-1 specification requirements. Coolants that only claim to meet the performance requirements of the Cat EC-1 specification may not meet all the minimum requirements.In order to be marketed as a product that meets Cat EC-1, all Cat EC-1 specification requirements must be met. Requirements include, but are not limited to the following:

Physical and Chemical Properties

Compatibility Characteristics

Bench Testing

Field TestingThe field test includes the use of the following requirements:

Radiator types

Minimum field test duration

Minimum number of diesel engines

Cat diesel engine models of the required minimum power rating

Cat does not warrant the quality or performance of non-Cat fluids.

Inorder to be used in Cat diesel engine cooling systems at the published service intervals, select a commercial extended life coolant that meets all the requirements given in Table 1 in this Special Publication.

Table 1

Technical Requirements for Commercial Extended Life Coolants

Specifications Cat EC-1 and "ASTM D6210"

Additional Requirements Organic Additive Technology (OAT) based on a combination of a monocarboxylic acid and a dicarboxylic acid

Phosphate, borate, and silicate free

Minimum typical tolyltriazole level of 900 ppm for new coolants

Minimum typical nitrite level of 500 ppm in new coolants"

Maintenance One time addition of an extender at the mid-life of the coolant in order to maintain the coolant nitrite level between 300 - 600 ppm Note: The Cat EC-1 specification describes the minimum requirements for extended life coolants.Use an extender that is recommended by the EC-1 coolant supplier at mid-life of the coolant.Commercial coolants that do not meet the minimum requirements defined in this Special Publication are not allowed for use in Cat engines.Commercial extended life coolant used in Cat engines must meet all requirements given in Table 1. If the ELC does meet the requirements, the service interval listed in this Special Publication may not be used. Follow the maintenance guidelines for the coolant from the supplier of the commercial extended life coolant. Follow the Cat guidelines for the quality of water and the specified coolant change interval.Note: Coolants must be tested against the Cat EC-1 specification requirements. Coolants that only claim to meet the performance requirements of the Cat EC-1 specification may not meet all the minimum requirements.In order to be marketed as a product that meets Cat EC-1, all Cat EC-1 specification requirements must be met. Requirements include, but are not limited to the following:

Physical and Chemical Properties

Compatibility Characteristics

Bench Testing

Field TestingThe field test includes the use of the following requirements:

Radiator types

Minimum field test duration

Minimum number of diesel engines

Cat diesel engine models of the required minimum power rating