Rating:

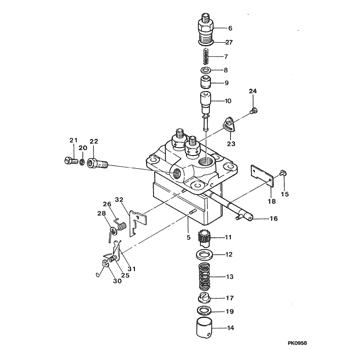

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

Construction machine K3E

Engine

K3E

Serial start-end

8201-

Info

Injector Nozzle

093500-1660

Injector nozzle:

0935001660

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

09450-02440

PUMP ASSY, INJECTI

Information:

Introduction

This Special Instruction has been written to provide procedural information for testing 7000 Series fuel nozzles.There is an extensive amount of information that relates to the setup and the calibration of the tools that will be used to test the fuel nozzles.Also, there is information on the setup and operation of the cleaning equipment that is necessary to clean the fuel nozzles.There is also a publication that provides record sheets. These record sheets can be used for recording and correlating the test data that is accumulated. The following information will summarize the related documentation.

For information on the setup, operation, and the calibration of the test equipment, refer to Tool Operating Manual, SEHS7292, "Using the 5P-4150 Nozzle Testing Group".

For information that relates to the setup and operation of the tools that are used to clean fuel nozzles, refer to Special Instruction, SEHS8627, "Using the 8S-2245 Nozzle Cleaning Tool Group".

Use the Special Instruction, SEHS8144, "Engine Nozzle Test Record" to record the results while you are testing each fuel nozzle. These record sheets are available through normal channels for literature distribution. The record sheets are available in pads that contain 50 sheets.Note: The publications that are mentioned above may contain information that must be referenced to test the fuel injection nozzles.Testing 7000 Series Fuel Nozzles

Ensure that you wear eye protection at all times during testing. When fuel injection nozzles are tested, test fluids travel through the orifices of the nozzle tip with high pressure. Under this amount of pressure, the test fluid can pierce the skin and cause serious injury to the operator. Always keep the tip of the fuel injection nozzle pointed away from the operator and into the fuel collector and extension.

Always ensure that

This Special Instruction has been written to provide procedural information for testing 7000 Series fuel nozzles.There is an extensive amount of information that relates to the setup and the calibration of the tools that will be used to test the fuel nozzles.Also, there is information on the setup and operation of the cleaning equipment that is necessary to clean the fuel nozzles.There is also a publication that provides record sheets. These record sheets can be used for recording and correlating the test data that is accumulated. The following information will summarize the related documentation.

For information on the setup, operation, and the calibration of the test equipment, refer to Tool Operating Manual, SEHS7292, "Using the 5P-4150 Nozzle Testing Group".

For information that relates to the setup and operation of the tools that are used to clean fuel nozzles, refer to Special Instruction, SEHS8627, "Using the 8S-2245 Nozzle Cleaning Tool Group".

Use the Special Instruction, SEHS8144, "Engine Nozzle Test Record" to record the results while you are testing each fuel nozzle. These record sheets are available through normal channels for literature distribution. The record sheets are available in pads that contain 50 sheets.Note: The publications that are mentioned above may contain information that must be referenced to test the fuel injection nozzles.Testing 7000 Series Fuel Nozzles

Ensure that you wear eye protection at all times during testing. When fuel injection nozzles are tested, test fluids travel through the orifices of the nozzle tip with high pressure. Under this amount of pressure, the test fluid can pierce the skin and cause serious injury to the operator. Always keep the tip of the fuel injection nozzle pointed away from the operator and into the fuel collector and extension.

Always ensure that