Rating:

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

Construction machine K3B

Engine

K3B

Serial start-end

7807-

Info

Injector Nozzle

093500-1660

Injector nozzle:

0935001660

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$611.44

11 Aug 2020

6.0[2.70] Pounds

-: -

Fuel Pump for Mitsubishi Tractor K3B Remanufactured 094500-1500 0945001500 094500 1500 2471020177 247-102-0177 247 102 0177

HHP provides parts equal or better in quality compared to the OE at a fraction of the cost. || Products are crafted with hard-wearing materials for long-lasting strength and durability. || Parts meet or exceed OEM specifications to ensure proper fit and function. || Request expert advice from Highway and Heavy Part's ASE Certified Technicians. || Products are only sourced from quality certified manufacturing facilities.

HHP provides parts equal or better in quality compared to the OE at a fraction of the cost. || Products are crafted with hard-wearing materials for long-lasting strength and durability. || Parts meet or exceed OEM specifications to ensure proper fit and function. || Request expert advice from Highway and Heavy Part's ASE Certified Technicians. || Products are only sourced from quality certified manufacturing facilities.

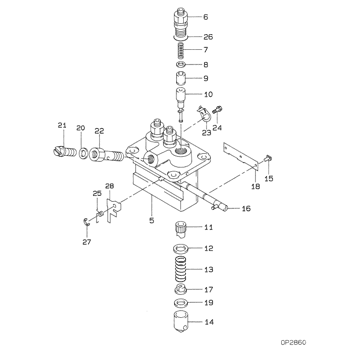

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09450-01500

PUMP ASSY, INJECTI

PFR3M

Include in ##:

09450-01500

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09450-01500

PUMP ASSY, INJECTI

Information:

1. Engine Will Not Start2. Engine Starts, Runs For a Few Moments, Then Stops3. Engine Misfiring or Running Rough4. Engine Runs Evenly, but Has Loss of Power5. Engine Does Not Have Enough Power6. Too Much Vibration7. Loud Combustion Noise (Sound)8. Loud Noise (Clicking) from Valve Compartment9. Oil in Cooling System10. Mechanical Noise (Knock) in Engine11. Little Movement of Rocker Arm and Too Much Valve Clearance12. Valve Spring Lock (Collet) Is Free13. Oil at the Exhaust14. Little or No Valve Clearance15. Engine Has Early Wear16. Coolant in Lubrication Oil17. Too Much Black or Gray Smoke18. Too Much White or Blue Smoke19. Engine Has Low Oil Pressure20. Engine Uses Too Much Lubrication Oil21. Engine Coolant Is Too Hot22. Exhaust Temperature Is Too High23. Troubleshooting Chart - Cooling SystemEngine Will Not Start Engine Starts, Runs For A Few Moments Then Stops Engine Misfiring Or Running Rough Engine Runs Evenly But Has Loss Of Power Engine Does Not Have Enough Power Too Much Vibration Loud Combustion Noise Loud Noise (Clicking) From Valve Compartment Oil In Cooling System Mechanical Noise (Knock) In Engine Little Movement Of Rocker Arm And Too Much Valve Clearance Valve Spring Lock Is Free Oil At The Exhaust Little Or No Valve Clearance Engine Has Early Wear Coolant In Lubrication Oil Too Much Black Or Dark Gray Smoke Too Much White Or Blue Smoke Engine Has Low Oil Pressure Engine Uses Too Much Lubrication Oil Engine Coolant Is Too Hot Exhaust Temperature Is Too High Fuel System

Cold Start Heater Tests

Basic Checks

A characteristic of the cold start heater is that the heater coil often appears wet. This happens because the diesel fuel does not burn completely and has the appearance that leakage exists. This condition is normal and should not be taken as an indication the ball valve has fuel leakage. If necessary, do the Leakage Test.Check the heater operation by checking that the inlet manifold is warm to the touch near the heater after approximately 10 seconds of operation.Check that the fuel tank and plumbing to the heater unit do not have leakage of fuel.Check fuel shutoff valve for correct operation. A poor seal can cause air to enter the system which will cause extra cranking of the engine before starting. Be sure all fuel connections are tight and not leaking air.Be sure the battery condition and state of charge is satisfactory, and all electrical connections are tight. A discharged battery or loose connection can cause reduced voltage at the starter motor terminals (slow cranking) or failure of the heater unit to be activated.

Do not operate the cold start heater too long at each time. Normal operation too long can cause components to get too hot and cause damage.

Leakage Test

Remove the cold start heater from the inlet manifold. Connect an air supply of 140 kPa (20 psi) maximum to the fuel inlet passage.

Do not use air with more pressure than 140 kPa (20 psi) or damage can be caused to the heating element.

Put the cold start heater

Cold Start Heater Tests

Basic Checks

A characteristic of the cold start heater is that the heater coil often appears wet. This happens because the diesel fuel does not burn completely and has the appearance that leakage exists. This condition is normal and should not be taken as an indication the ball valve has fuel leakage. If necessary, do the Leakage Test.Check the heater operation by checking that the inlet manifold is warm to the touch near the heater after approximately 10 seconds of operation.Check that the fuel tank and plumbing to the heater unit do not have leakage of fuel.Check fuel shutoff valve for correct operation. A poor seal can cause air to enter the system which will cause extra cranking of the engine before starting. Be sure all fuel connections are tight and not leaking air.Be sure the battery condition and state of charge is satisfactory, and all electrical connections are tight. A discharged battery or loose connection can cause reduced voltage at the starter motor terminals (slow cranking) or failure of the heater unit to be activated.

Do not operate the cold start heater too long at each time. Normal operation too long can cause components to get too hot and cause damage.

Leakage Test

Remove the cold start heater from the inlet manifold. Connect an air supply of 140 kPa (20 psi) maximum to the fuel inlet passage.

Do not use air with more pressure than 140 kPa (20 psi) or damage can be caused to the heating element.

Put the cold start heater