Rating:

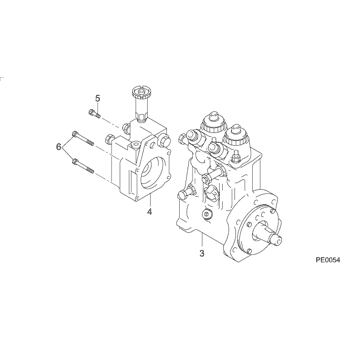

Information pump assy, supply Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Diesel High Pressure Fuel Injection Pump Compatible withHINO E13C Engine 094000-1031 094000-0421 22100-E0303 22100-E0302

HUIBEIMI Mechanical high pressure fuel pump Steady fuel supply improves ride comfort and response speed || The fuel pump has the advantages of simple structure, convenient maintenance and reduced operating cost || The common rail high pressure fuel pump controls the amount and time of fuel injection to improve combustion efficiency || The high-pressure fuel pump can improve the dynamic performance of the engine, making the vehicle accelerate faster and more powerful || Diesel High Pressure Fuel Injection Pump Compatible withHINO E13C Engine 094000-1031 094000-0421 22100-E0303 22100-E0302

HUIBEIMI Mechanical high pressure fuel pump Steady fuel supply improves ride comfort and response speed || The fuel pump has the advantages of simple structure, convenient maintenance and reduced operating cost || The common rail high pressure fuel pump controls the amount and time of fuel injection to improve combustion efficiency || The high-pressure fuel pump can improve the dynamic performance of the engine, making the vehicle accelerate faster and more powerful || Diesel High Pressure Fuel Injection Pump Compatible withHINO E13C Engine 094000-1031 094000-0421 22100-E0303 22100-E0302

Diesel Fuel Injection Pump 094000-0421 22100-E0302 22100-E0303 094000-1031

VSQQGPSV Through high-precision pressure, fuel can be fully atomized, promoting complete combustion and improving fuel economy. || High precision manufacturing processes ensure the accuracy of fuel metering and injection. || Excellent design minimizes noise and vibration during operation, providing you with a quieter and more comfortable driving experience. || A good fuel injection pump is crucial for engine power, fuel efficiency, and fuel economy. || Diesel Fuel Injection Pump 094000-0421 22100-E0302 22100-E0303 094000-1031

VSQQGPSV Through high-precision pressure, fuel can be fully atomized, promoting complete combustion and improving fuel economy. || High precision manufacturing processes ensure the accuracy of fuel metering and injection. || Excellent design minimizes noise and vibration during operation, providing you with a quieter and more comfortable driving experience. || A good fuel injection pump is crucial for engine power, fuel efficiency, and fuel economy. || Diesel Fuel Injection Pump 094000-0421 22100-E0302 22100-E0303 094000-1031

Diesel Oil Pump Model:094000-0421 22100-E0302 22100-E0303 094000-1031

WSVKJLGR Tip: Before placing your order, please carefully check and confirm that the model and part number of the fuel injection pump you order matches the specifications of your specific equipment. || Simple installation: reasonable design and simple installation steps to ensure the normal function of the fuel injection pump. || Precise control: Precise control of fuel flow makes engine power output more stable. || Stable pressure: stable output of fuel pressure under various working conditions to ensure continuous and stable operation of the engine. || High-precision injection: The injection pump adopts advanced technology to achieve high-precision fuel injection to ensure full fuel combustion and improve engine performance.

WSVKJLGR Tip: Before placing your order, please carefully check and confirm that the model and part number of the fuel injection pump you order matches the specifications of your specific equipment. || Simple installation: reasonable design and simple installation steps to ensure the normal function of the fuel injection pump. || Precise control: Precise control of fuel flow makes engine power output more stable. || Stable pressure: stable output of fuel pressure under various working conditions to ensure continuous and stable operation of the engine. || High-precision injection: The injection pump adopts advanced technology to achieve high-precision fuel injection to ensure full fuel combustion and improve engine performance.

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09400-01031

22100-E030

PUMP ASSY, SUPPLY

Information:

start by:a) remove fuel injection pump housing and governor 1. Install the fuel injection pump housing on tool (A).2. Remove the bolts (1) that hold the governor housing (2) to the fuel injection pump housing.3. Remove the governor housing (2). 4. Remove two springs (4) and the seat (5) from the governor housing.5. Remove the seat (7) from the shaft.6. Remove the spring (6) from the shaft.7. Remove the cover (3) from the pump housing. 8. Remove the shaft (8) and the lever (9) from the pump housing. 9. Remove the thrust collar (11) from the shaft.10. Remove the cover (10) from the pump housing. 11. Loosen the two bolts (13) that hold the torque spring assembly (12) and remove it from the pump housing. 12. Remove the pin (15) from the pump housing.13. Remove the screw (14) and the nut (16) from the pump housing.14. Remove the ring that holds the lever and remove the lever (18) from the dowel (17).15. Remove the dowel (17) from the pump housing. Dowel does not need to be removed unless camshaft is to be removed.

Pull on the shield only a small amount in each location so it will not have distortion or damage. A damaged shield must be replaced.

16. Remove the shield (19) from the camshaft with tool (B). 17. Install the timing pin (C) to hold the camshaft.18. Remove the bolts (20) that hold the flyweight assembly to the camshaft. 19. Remove the flyweight assembly (21) from the camshaft.20. Remove the timing pin (C) from the pump housing.Connection Of Governor To Fuel Injection Pump Housing

1. Put the fuel injection pump housing on the bracket assembly (A).2. Install the timing pin (B) to hold the camshaft.3. Put the flyweight assembly (1) in position on the camshaft. Be sure the pin that holds the shaft (2) is in position on the back of the flyweight assembly.4. Install the bolts that hold the flyweight assembly to the camshaft and tighten to a torque of 10 2 lb. ft. (1.38 0.28 mkg).5. Remove the timing pin (B). 6. Put the shield (3) in position over the flyweights. 7. Use the driver (C) to install the shield the remainder of the way on to the camshaft. 8. Put a new O-ring seal on the dowel (4) and install the dowel in the pump housing. Make the dowel even with the machined surface of the counterbore on the outside of the housing. 9. Put the lever (8) on the dowel (4) and install the ring that holds it on the dowel.10. Install the screw (6) and the nut (7) in the pump housing.11. Install the pin (5) in the pump housing. 12. Put the torque spring assembly (10) in position on the housing and tighten the two bolts (11) that hold it to the housing.13. Install the cover (9) on the pump housing. 14. Put the thrust collar (13) in position between the flyweights. Lift the flyweights up with a piece of wire

Pull on the shield only a small amount in each location so it will not have distortion or damage. A damaged shield must be replaced.

16. Remove the shield (19) from the camshaft with tool (B). 17. Install the timing pin (C) to hold the camshaft.18. Remove the bolts (20) that hold the flyweight assembly to the camshaft. 19. Remove the flyweight assembly (21) from the camshaft.20. Remove the timing pin (C) from the pump housing.Connection Of Governor To Fuel Injection Pump Housing

1. Put the fuel injection pump housing on the bracket assembly (A).2. Install the timing pin (B) to hold the camshaft.3. Put the flyweight assembly (1) in position on the camshaft. Be sure the pin that holds the shaft (2) is in position on the back of the flyweight assembly.4. Install the bolts that hold the flyweight assembly to the camshaft and tighten to a torque of 10 2 lb. ft. (1.38 0.28 mkg).5. Remove the timing pin (B). 6. Put the shield (3) in position over the flyweights. 7. Use the driver (C) to install the shield the remainder of the way on to the camshaft. 8. Put a new O-ring seal on the dowel (4) and install the dowel in the pump housing. Make the dowel even with the machined surface of the counterbore on the outside of the housing. 9. Put the lever (8) on the dowel (4) and install the ring that holds it on the dowel.10. Install the screw (6) and the nut (7) in the pump housing.11. Install the pin (5) in the pump housing. 12. Put the torque spring assembly (10) in position on the housing and tighten the two bolts (11) that hold it to the housing.13. Install the cover (9) on the pump housing. 14. Put the thrust collar (13) in position between the flyweights. Lift the flyweights up with a piece of wire