Rating:

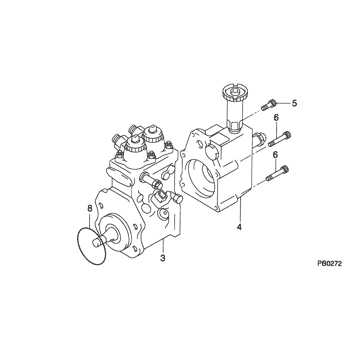

Information pump assy, supply Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

094000-0382 094000-0381 6156-71-1112 6156-71-1111 6156-71-1110 Fuel Injection Pump for Komatsu SAA6D125E-3 Engine PC400-7 PC450-7 PC460-7 PC480-7 Eacavator

HIRINTOL 🔸Replace Part Number: 094000-0382, 094000-0381, 6156-71-1112, 6156-71-1111, 6156-71-1110 || 🔸Compatible Model: for Komatsu SAA6D125E-3 SAA6D125E-3A SAA6D125E-3B Engine; for Komatsu PC400-7 PC450-7 PC460-7 PC480-7 Eacavator || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions. || 🔸Easy Installation: standard interface design, easy installation, plug and play, no professional skills required.

HIRINTOL 🔸Replace Part Number: 094000-0382, 094000-0381, 6156-71-1112, 6156-71-1111, 6156-71-1110 || 🔸Compatible Model: for Komatsu SAA6D125E-3 SAA6D125E-3A SAA6D125E-3B Engine; for Komatsu PC400-7 PC450-7 PC460-7 PC480-7 Eacavator || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions. || 🔸Easy Installation: standard interface design, easy installation, plug and play, no professional skills required.

IMIFAFTAbT Fuel Injection Pump 094000-0382 094000-0381 Fits For Komatsu SAA6D125E-3 SAA6D125E-3A SAA6D125E-3B3G Engine PC400-7 PC450-7 PC460-7 Excavator

IMIFAFTAbT Part Name:Fuel Injection Pump 094000-0382 094000-0381 || Part Number:094000-0382 094000-0381 0940000382 0940000381 || APPlication: Fits For Komatsu SAA6D125E-3 SAA6D125E-3A SAA6D125E-3B3G Engine PC400-7 PC450-7 PC460-7 Excavator || If you are not sure if the product is suitable please leave us a message and send us your original || product picture and part number and we will send the correct part after confirmation

IMIFAFTAbT Part Name:Fuel Injection Pump 094000-0382 094000-0381 || Part Number:094000-0382 094000-0381 0940000382 0940000381 || APPlication: Fits For Komatsu SAA6D125E-3 SAA6D125E-3A SAA6D125E-3B3G Engine PC400-7 PC450-7 PC460-7 Excavator || If you are not sure if the product is suitable please leave us a message and send us your original || product picture and part number and we will send the correct part after confirmation

094000-0382 0940000382 Fuel Injection Pump Suitable for Komatsu SAA6D125E-3 PC400-7 PC450-7 PC460-7

OfkZynodor Part Name:Fuel Injection Pump || Part Number:094000-0382 0940000382 || Application:Suitable for Komatsu SAA6D125E-3 PC400-7 PC450-7 PC460-7 || Please make sure to carefully compare the photos and check the part numbers before making the purchase. If you are unable to confirm your engine model or part number, please leave us a message and we will assist you in confirming that the product you purchase is the one you need. || Your order is not merely a single purchase but the beginning of a cooperative journey, aiming to ensure the safe and smooth operation of your vehicle. We are proud to offer you reliable precision engineering components and unparalleled services.

OfkZynodor Part Name:Fuel Injection Pump || Part Number:094000-0382 0940000382 || Application:Suitable for Komatsu SAA6D125E-3 PC400-7 PC450-7 PC460-7 || Please make sure to carefully compare the photos and check the part numbers before making the purchase. If you are unable to confirm your engine model or part number, please leave us a message and we will assist you in confirming that the product you purchase is the one you need. || Your order is not merely a single purchase but the beginning of a cooperative journey, aiming to ensure the safe and smooth operation of your vehicle. We are proud to offer you reliable precision engineering components and unparalleled services.

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09400-00382

PUMP ASSY, SUPPLY

Information:

(8) Diameter of camshaft journals: No. 1 journal ... 50.71 to 50.737 mm (1.9965 to 1.9975 in.)Minimum permissible diameter ... 50.660 mm (1.9945 in.)No. 2 journal ... 50.457 to 50.483 mm (1.9865 to 1.9875 in.)Minimum permissible diameter ... 50.406 mm (1.9845 in.)No. 3 journal ... 50.203 to 50.229 mm (1.9765 to 1.9775 in.)Minimum permissible diameter ... 50.152 mm (1.9745 in.)No. 4 journal ... 49.949 to 49.975 mm (1.9665 to 1.9675 in.)Minimum permissible diameter ... 48.898 mm (1.9645 in.)(See topic Cylinder Block for camshaft bore specifications.) (10) Height of the lobes of the camshaft. To get height use the procedure that follows:A. Measure base circle (11).B. Add lobe lift (9) to base circle measurement. Total is camshaft lobe height. Camshaft lobe lift (9) is:Intake ... 7.704 to 7.780 mm (.3033 to .3063 in.)Exhaust ... 7.805 to 7.881 mm (.3073 to .3103 in.)Minimum permissible height of lobes is 0.25 mm (.010 in.) less than measurement in Step B.(12) Torque for camshaft bolt ... 70 N m (50 lb.ft.)(13) End play of camshaft ... 0.10 to 0.41 mm (.004 to .016 in.) Maximum permissible end play ... 0.53 mm (.021 in.)(14) Camshaft thrust washer: Outside diameter ... 72.95 to 73.00 mm (2.872 to 2.874 in.)Cylinder block recess diameter for thrust washer ... 73.03 to 73.28 mm (2.875 to 2.885 in.)Clearance of washer in recess ... 0.03 to 0.33 mm (.001 to .013 in.)Inside diameter ... 44.45 mm (1.750 in.)Thickness ... 5.49 to 5.54 mm (.216 to .218 in.)Cylinder block recess depth for thrust washer ... 5.41 to 5.54 mm (.213 to .216 in.)Projection of thrust washer above cylinder block front face ... 0.00 to 0.13 mm (.000 to .005 in.)(15) Camshaft gear: Bore diameter ... 34.93 to 34.95 mm (1.375 to 1.376 in.)Outside diameter of camshaft hub ... 34.928 to 34.943 mm (1.3751 to 1.3757 in.)Clearance of gear on hub ... -0.018 to +0.023 mm (.-.0007 to +.0009 in.)