Rating:

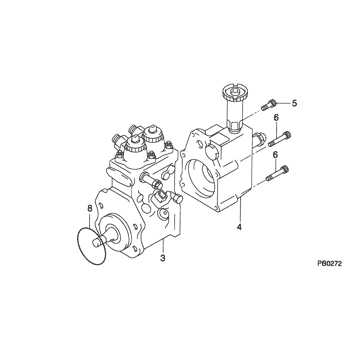

Information pump assy, supply Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump 094000-0323 6217-71-1120 Compatible with Komatsu 6D140E-3 Diesel Engine

Starhycfa Product name:Fuel Injection Pump || Part Number:094000-0323 6217-71-1120 || APPlication:Compatible with Komatsu 6D140E-3 Diesel Engine || 1.Please carefully compare the pictures or OE numbers to match your original parts before purchasing the product. || 2.Please make sure that the model number, part number and photo is the same as yours before order. To Avoid placing wrong orders and wasting your precious time.

Starhycfa Product name:Fuel Injection Pump || Part Number:094000-0323 6217-71-1120 || APPlication:Compatible with Komatsu 6D140E-3 Diesel Engine || 1.Please carefully compare the pictures or OE numbers to match your original parts before purchasing the product. || 2.Please make sure that the model number, part number and photo is the same as yours before order. To Avoid placing wrong orders and wasting your precious time.

Fuel Injection Pump 094000-0323 6217-71-1111 for Komatsu Engine SA6D140E Loader WA500-3

ADPelcote Part number:094000-0323 || Applications:for Komatsu Engine SA6D140E Loader WA500-3

ADPelcote Part number:094000-0323 || Applications:for Komatsu Engine SA6D140E Loader WA500-3

094000-0323 6217-71-1120 Fuel Injection Pump Compatible with Komatsu 6D140E-3 Diesel Engine

GSHLGAO Part Name: Fuel Injection Pump Assembly || Part Number: 094000-0323 6217-71-1120 || Compatible with the Komatsu 6D140E-3 diesel engine, these parts offer reliable performance, precision engineering, and durability. Engineered to meet high quality standards, they provide optimal functionality and longevity. Trust in them for superior performance and peace of mind. || Please ensure that the confirmation is based on the accurate part number and not solely on the model number provided. || 11. Kindly provide your residential or business address, excluding P.O. Box addresses, and ensure that your contact details are accurate.

GSHLGAO Part Name: Fuel Injection Pump Assembly || Part Number: 094000-0323 6217-71-1120 || Compatible with the Komatsu 6D140E-3 diesel engine, these parts offer reliable performance, precision engineering, and durability. Engineered to meet high quality standards, they provide optimal functionality and longevity. Trust in them for superior performance and peace of mind. || Please ensure that the confirmation is based on the accurate part number and not solely on the model number provided. || 11. Kindly provide your residential or business address, excluding P.O. Box addresses, and ensure that your contact details are accurate.

You can buy:

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09400-00323

PUMP ASSY, SUPPLY

Information:

Introduction

This Special Instruction explains the calibration procedure for the heavy sleeve (commonly called the thick sleeve) metering fuel system. This Special Instruction shows:* The differences between the new 133-8985 Governor And Fuel Injection Pump Group, (HSMFS) and the 109-0324 Governor And Fuel Injection Pump Group, Sleeve Metering Fuel System (SMFS).* Calibration procedure for setting the 124-5932 Lever Assemblies.Recommended Tools

* 4C-9738 Torque Screwdriver set at 1.7 N m (15 lb in).* 4C-9738 Torque Screwdriver set at 4.0 N m (35 lb in).Required Tooling

* 3P-2200 Sleeve Setting Group: The HSMFS Injection Pump Group requires the use of many of the past 3208 Calibration Tools. A few new dedicated tools are required for the HSMFS.

Illustration 1. Parts included, and parts required but not included within the 3P-2200 Sleeve Setting Group. See Chart 1 and Chart 2 for item and part numbers. The 3P-2200 Sleeve Setting Group is used to set, test and adjust SMFS Injection Pump Groups.Reference, Special Instruction; SMHS6988, "Use Of 3P-2200 Calibration Tool Group".Special Instruction, SMHS7013, "Use Of The 5P-4203 Field Service Tool Group Or 5P-6577 Fuel Setting Tool Group". All tools may be stored in a 6V-3073 Plastic Case. The lid contains a 6V-4094 Liner and 6V-4873 Packing in the bottom for protection. The 6V-4873 Packing is topped with a 2P-8289 Tool Holder Block.

Illustration 2. The 5P-4203 Tool Group. See chart 3. for item and part number. 109-0324 Governor And Fuel Injection Pump Group (SMFS).

Illustration 3. View of the 109-0324 Governor And Fuel Injection Pump Group (SMFS). (1) 9N-5820 Lever. (2) 124-5941 Shaft. (3) 9Y-7791 Sleeve.The SMFS Injection Pump Group 9.0 mm (.35 in) 9Y-7791 Sleeve (3) has four 9N-5820 Levers (1) on each 124-5941 Shaft (2). The 9N-5820 Levers are indexed from the front. The 9Y-7791 Sleeve and 9N-5820 Lever indexes with the groove in the 9Y-7791 Sleeve.133-8985 Governor And Fuel Injection Pump Group (HSMFS).

Illustration 4. View of the HSMFS Injection Pump Group.

(1) 124-5932 Lever Assembly. (2) 124-5941 Shaft. (3) 124-5934 Sleeve.

Illustration 5. View of the HSMFS Injection Pump Group.

(1) 124-5932 Lever Assembly. (4) 126-7232 Dowel.The new 124-5934 Sleeve (3) is thicker than the former 9Y-7791 Sleeve (3). The new 124-5934 Sleeve can be operated at higher injection pressures needed for emissions control. As a result of its increased thickness, the 124-5934 Sleeve can not be indexed from the front. It must be indexed between two 124-5934 Sleeves.The new 124-5932 Lever Assembly (1) has a 126-7232 Dowel (4) that is split in half. The split 126-7232 Dowel is positioned between two 133-8984 Fuel Pump Assemblies and indexes two 124-5934 Sleeves (3) at the same time.

Illustration 6. Side view of one bank of the HSMFS Injection Pump Group. (1) 124-5932 Lever Assemblies. (2) 124-5941 Shaft.There are two 124-5932 Lever Assemblies (1) on the 124-5941 Shaft (2) of the HSMFS Injection Pump Group, instead of four 9N-5820 levers (1) on each 124-5941 Shaft (2) on the SMFS Injection Pump Group. Each 124-5932 Lever Assembly is positioned in between two and indexes two 133-8984 Fuel Pump Assemblies and two 124-5934

This Special Instruction explains the calibration procedure for the heavy sleeve (commonly called the thick sleeve) metering fuel system. This Special Instruction shows:* The differences between the new 133-8985 Governor And Fuel Injection Pump Group, (HSMFS) and the 109-0324 Governor And Fuel Injection Pump Group, Sleeve Metering Fuel System (SMFS).* Calibration procedure for setting the 124-5932 Lever Assemblies.Recommended Tools

* 4C-9738 Torque Screwdriver set at 1.7 N m (15 lb in).* 4C-9738 Torque Screwdriver set at 4.0 N m (35 lb in).Required Tooling

* 3P-2200 Sleeve Setting Group: The HSMFS Injection Pump Group requires the use of many of the past 3208 Calibration Tools. A few new dedicated tools are required for the HSMFS.

Illustration 1. Parts included, and parts required but not included within the 3P-2200 Sleeve Setting Group. See Chart 1 and Chart 2 for item and part numbers. The 3P-2200 Sleeve Setting Group is used to set, test and adjust SMFS Injection Pump Groups.Reference, Special Instruction; SMHS6988, "Use Of 3P-2200 Calibration Tool Group".Special Instruction, SMHS7013, "Use Of The 5P-4203 Field Service Tool Group Or 5P-6577 Fuel Setting Tool Group". All tools may be stored in a 6V-3073 Plastic Case. The lid contains a 6V-4094 Liner and 6V-4873 Packing in the bottom for protection. The 6V-4873 Packing is topped with a 2P-8289 Tool Holder Block.

Illustration 2. The 5P-4203 Tool Group. See chart 3. for item and part number. 109-0324 Governor And Fuel Injection Pump Group (SMFS).

Illustration 3. View of the 109-0324 Governor And Fuel Injection Pump Group (SMFS). (1) 9N-5820 Lever. (2) 124-5941 Shaft. (3) 9Y-7791 Sleeve.The SMFS Injection Pump Group 9.0 mm (.35 in) 9Y-7791 Sleeve (3) has four 9N-5820 Levers (1) on each 124-5941 Shaft (2). The 9N-5820 Levers are indexed from the front. The 9Y-7791 Sleeve and 9N-5820 Lever indexes with the groove in the 9Y-7791 Sleeve.133-8985 Governor And Fuel Injection Pump Group (HSMFS).

Illustration 4. View of the HSMFS Injection Pump Group.

(1) 124-5932 Lever Assembly. (2) 124-5941 Shaft. (3) 124-5934 Sleeve.

Illustration 5. View of the HSMFS Injection Pump Group.

(1) 124-5932 Lever Assembly. (4) 126-7232 Dowel.The new 124-5934 Sleeve (3) is thicker than the former 9Y-7791 Sleeve (3). The new 124-5934 Sleeve can be operated at higher injection pressures needed for emissions control. As a result of its increased thickness, the 124-5934 Sleeve can not be indexed from the front. It must be indexed between two 124-5934 Sleeves.The new 124-5932 Lever Assembly (1) has a 126-7232 Dowel (4) that is split in half. The split 126-7232 Dowel is positioned between two 133-8984 Fuel Pump Assemblies and indexes two 124-5934 Sleeves (3) at the same time.

Illustration 6. Side view of one bank of the HSMFS Injection Pump Group. (1) 124-5932 Lever Assemblies. (2) 124-5941 Shaft.There are two 124-5932 Lever Assemblies (1) on the 124-5941 Shaft (2) of the HSMFS Injection Pump Group, instead of four 9N-5820 levers (1) on each 124-5941 Shaft (2) on the SMFS Injection Pump Group. Each 124-5932 Lever Assembly is positioned in between two and indexes two 133-8984 Fuel Pump Assemblies and two 124-5934