Rating:

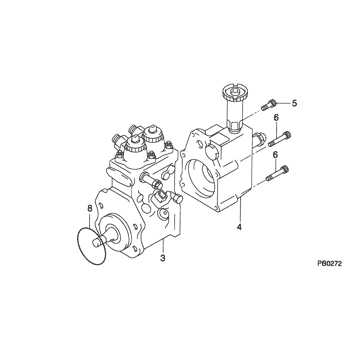

Information pump assy, supply Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

HGHJKZYZ Diesel Fuel Injection Pump Compatible with PC600-7 Excavator Models 6217-71-1121 094000-0322 6217-71-1122 094000-0323

HGHJKZYZ Designed Compatible With compatibility with PC600-7 excavators, ensuring integration and performance. || Equipped with components that enhance durability and reliability in demanding work environments. || Engineered Compatible With efficient fuel delivery, promoting improved engine performance and reduced emissions. || Offers precise fuel injection timing, contributing to better fuel economy and overall machine efficiency. || Compatible with multiple part numbers including 6217-71-1121, 094000-0322, 6217-71-1122, and 094000-0323 Compatible With flexible replacement options. || Suitable Compatible With various applications within the construction and heavy machinery sectors, accommodating a wide range of operational needs. || Designed Compatible With easy installation, allowing Compatible With quick replacement and minimal downtime during maintenance.

HGHJKZYZ Designed Compatible With compatibility with PC600-7 excavators, ensuring integration and performance. || Equipped with components that enhance durability and reliability in demanding work environments. || Engineered Compatible With efficient fuel delivery, promoting improved engine performance and reduced emissions. || Offers precise fuel injection timing, contributing to better fuel economy and overall machine efficiency. || Compatible with multiple part numbers including 6217-71-1121, 094000-0322, 6217-71-1122, and 094000-0323 Compatible With flexible replacement options. || Suitable Compatible With various applications within the construction and heavy machinery sectors, accommodating a wide range of operational needs. || Designed Compatible With easy installation, allowing Compatible With quick replacement and minimal downtime during maintenance.

YRGGHUI Diesel Engine Common Rail Fuel Injection Pump 094000-0322 6217-71-1121 Excavator Pump

YRGGHUI OEM Number: 094000-0322 6217-71-1121 || Type: Automotive AC Generator, Automotive Generator, AC Generator || Wear resistant and durable, with a long service life and easy installation (professional installation recommended) || Please confirm that the product must match your vehicle when purchasing! If you are unsure, please tell me the part number or send me some photos. thank you. || Automotive Generator: Silent power generation, safe and reliable, stable power generation, solves abnormal noise, stabilizes current and voltage to reduce fuel consumption, stable performance, energy-saving and environmentally friendly, increases intake pressure, enhances power output

YRGGHUI OEM Number: 094000-0322 6217-71-1121 || Type: Automotive AC Generator, Automotive Generator, AC Generator || Wear resistant and durable, with a long service life and easy installation (professional installation recommended) || Please confirm that the product must match your vehicle when purchasing! If you are unsure, please tell me the part number or send me some photos. thank you. || Automotive Generator: Silent power generation, safe and reliable, stable power generation, solves abnormal noise, stabilizes current and voltage to reduce fuel consumption, stable performance, energy-saving and environmentally friendly, increases intake pressure, enhances power output

Fuel Injection Pump for Komatsu SA6D140E Engine PC400-7 PC600-7 PC600-8 Excavator WA500-3 Loader 6217-71-1120 6217-71-1121 094000-0322

KoovDem Part Number: 094000-0320 094000-0321 094000-0322 094000-0323 6217-71-1120 6217-71-1121 6217-71-1122 || Application:For Komatsu PC400-7 PC600-7 PC600-8 Excavator, WA500-3 Loader || This engine model is designed for Komatsu SA6D140E and SA6D140E-3 engines, delivering reliable and powerful performance. Engineered to meet specific technical requirements, it ensures optimal functionality and efficiency. Known for its durability and performance, it is a top choice for maintaining or upgrading Komatsu engines. || Friendly reminder: Before proceeding to replace the fuel pump, make sure it is compatible with the one you are looking to replace. If you are unsure about the compatibility, feel free to provide us with your model number for further assistance. || Service: We offer a 6-month warranty on all products, as well as 24-hour customer support. If you have any questions or concerns about your purchase, please do not hesitate to reach out to us via email.

KoovDem Part Number: 094000-0320 094000-0321 094000-0322 094000-0323 6217-71-1120 6217-71-1121 6217-71-1122 || Application:For Komatsu PC400-7 PC600-7 PC600-8 Excavator, WA500-3 Loader || This engine model is designed for Komatsu SA6D140E and SA6D140E-3 engines, delivering reliable and powerful performance. Engineered to meet specific technical requirements, it ensures optimal functionality and efficiency. Known for its durability and performance, it is a top choice for maintaining or upgrading Komatsu engines. || Friendly reminder: Before proceeding to replace the fuel pump, make sure it is compatible with the one you are looking to replace. If you are unsure about the compatibility, feel free to provide us with your model number for further assistance. || Service: We offer a 6-month warranty on all products, as well as 24-hour customer support. If you have any questions or concerns about your purchase, please do not hesitate to reach out to us via email.

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09400-00322

PUMP ASSY, SUPPLY

Information:

3. With dial indicator set at "0" (zero) at location (A), turn the crankshaft and read the indicator at locations (B), (C) and (D).4. The difference between lower and higher measurements taken at all four points must not be more than 0.20 mm (.008 in.)Bore Runout

Write the dial indicator measurements with their positive (+) and negative (-) notation (signs). This notation is necessary when the calculations are made in the chart correctly. 1. Fasten a dial indicator to the crankshaft flange so the 7H1940 Universal Attachment of the indicator is in contact with the inner flywheel housing bore at location (C). Adjust the dial indicator to "0" (zero). Push the crankshaft up against the top crankshaft bearing. Write the measurement for bearing clearance on line 1 in column (C) of the chart.2. Divide the measurement from Step 1 by 2. Write this number on line in columns (B) and (D). 3. Turn the crankshaft to put the dial indicator at (A). Adjust the dial indicator to "0" (zero).4. Turn the crankshaft counterclockwise to put the dial indicator at (B). Write the measurement in the chart.5. Turn the crankshaft counterclockwise to put the dial indicator at (C). Write the measurement in the chart.6. Turn the crankshaft counterclockwise to put the dial indicator at (D). Write the measurement in the chart.7. Add lines I and II by columns. 8. Subtract the smaller number from the larger number in line II in columns (B) and (D). The result is the horizontal "eccentricity" (out of round). Line III, column (C) is the vertical eccentricity. 9. On the graph for total eccentricity, find the point of intersection of the lines for vertical eccentricity and horizontal eccentricity.10. If the point of intersection is in the range marked "Acceptable" the bore is in alignment. If the point of intersection is in the range marked "Not Acceptable", the flywheel housing must be changed.

Write the dial indicator measurements with their positive (+) and negative (-) notation (signs). This notation is necessary when the calculations are made in the chart correctly. 1. Fasten a dial indicator to the crankshaft flange so the 7H1940 Universal Attachment of the indicator is in contact with the inner flywheel housing bore at location (C). Adjust the dial indicator to "0" (zero). Push the crankshaft up against the top crankshaft bearing. Write the measurement for bearing clearance on line 1 in column (C) of the chart.2. Divide the measurement from Step 1 by 2. Write this number on line in columns (B) and (D). 3. Turn the crankshaft to put the dial indicator at (A). Adjust the dial indicator to "0" (zero).4. Turn the crankshaft counterclockwise to put the dial indicator at (B). Write the measurement in the chart.5. Turn the crankshaft counterclockwise to put the dial indicator at (C). Write the measurement in the chart.6. Turn the crankshaft counterclockwise to put the dial indicator at (D). Write the measurement in the chart.7. Add lines I and II by columns. 8. Subtract the smaller number from the larger number in line II in columns (B) and (D). The result is the horizontal "eccentricity" (out of round). Line III, column (C) is the vertical eccentricity. 9. On the graph for total eccentricity, find the point of intersection of the lines for vertical eccentricity and horizontal eccentricity.10. If the point of intersection is in the range marked "Acceptable" the bore is in alignment. If the point of intersection is in the range marked "Not Acceptable", the flywheel housing must be changed.