Rating:

Information pump assy, supply Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Diesel HP0 Fuel Pump 094000-0151 094000-0152 ME131603 Compatible With MITSUBISHI 6M60T

WSVKJLGR Tip: Before placing your order, please carefully check and confirm that the model and part number of the fuel injection pump you order matches the specifications of your specific equipment. || Simple installation: reasonable design and simple installation steps to ensure the normal function of the fuel injection pump. || Precise control: Precise control of fuel flow makes engine power output more stable. || Stable pressure: stable output of fuel pressure under various working conditions to ensure continuous and stable operation of the engine. || High-precision injection: The injection pump adopts advanced technology to achieve high-precision fuel injection to ensure full fuel combustion and improve engine performance.

WSVKJLGR Tip: Before placing your order, please carefully check and confirm that the model and part number of the fuel injection pump you order matches the specifications of your specific equipment. || Simple installation: reasonable design and simple installation steps to ensure the normal function of the fuel injection pump. || Precise control: Precise control of fuel flow makes engine power output more stable. || Stable pressure: stable output of fuel pressure under various working conditions to ensure continuous and stable operation of the engine. || High-precision injection: The injection pump adopts advanced technology to achieve high-precision fuel injection to ensure full fuel combustion and improve engine performance.

Fuel injection Pump 094000-0151 ME131603 for Mitsubishi Engine 6M60T

AUCALIWI Part number:094000-0151,ME131603 || Application:for Mitsubishi Engine 6M60T

AUCALIWI Part number:094000-0151,ME131603 || Application:for Mitsubishi Engine 6M60T

Gvgsgtyu Common Rail HP0 Fuel Injection Pump 094000-0097 8-94392714-6 8943927146 094000-0152 ME131603

Gvgsgtyu 094000-0097 8-94392714-6 8943927146 094000-0152 ME131603 || Easy installation: No complex debugging process required, users can use it directly, greatly saving installation time and labor costs. || Easy to maintain: The product design emphasizes practicality, easy disassembly and cleaning, effectively reducing maintenance costs and time. || Reduce vibration: During the operation of the fuel pump, it can effectively reduce vibration transmission, ensure smooth operation of the equipment, and reduce noise and wear. || Long lifespan: Through advanced manufacturing processes and high-quality materials, the service life of fuel pumps has been effectively extended, improving the overall integrity of the equipment.

Gvgsgtyu 094000-0097 8-94392714-6 8943927146 094000-0152 ME131603 || Easy installation: No complex debugging process required, users can use it directly, greatly saving installation time and labor costs. || Easy to maintain: The product design emphasizes practicality, easy disassembly and cleaning, effectively reducing maintenance costs and time. || Reduce vibration: During the operation of the fuel pump, it can effectively reduce vibration transmission, ensure smooth operation of the equipment, and reduce noise and wear. || Long lifespan: Through advanced manufacturing processes and high-quality materials, the service life of fuel pumps has been effectively extended, improving the overall integrity of the equipment.

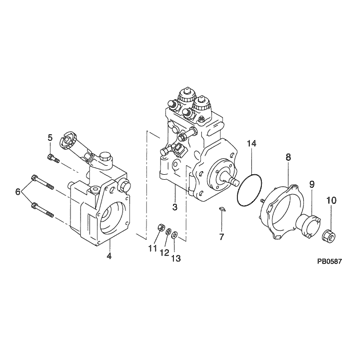

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09400-00152

PUMP ASSY, SUPPLY

CRS-HP0

ME131603

MITSUBISHI

Include in ##:

09400-00152

as PUMP ASSY, SUPPLY

Cross reference number

Part num

Firm num

Firm

Name

09400-00152

ME131603

PUMP ASSY, SUPPLY

Test Calibration Data:

01EL015200

ME131603

01EL015200

ME131603

01EL015200

ME131603

0940000150

ME131603

0940000151

ME131603

0940000152

ME131603

Information:

Service Group Chart

Removal and Installation

1. Remove the pump and governor from the engine. Refer to the Service Manual.

When a replacement fuel injection pump and governor is installed on an engine (or when replacement parts are put in a fuel injection pump and governor), use the information on the engine information plate and always check engine low idle speed, set point and the fuel setting dimension. These settings and dimensions must be checked and adjustments made by a mechanic that has the necessary training in fuel system maintenance. Before the fuel system checks and adjustment are made, remove the original factory fuel system seal. After all fuel system work has been completed, install your Dealer seal as a replacement seal. Refer to Fuel System and Related Information or Fuel Setting Information for additional specifications.

2. Put the new service pump group in a 2P8315 Bracket Assembly (1) so it will be easier to work on. Remove the shut-off solenoid and the solenoid ground wire from the old fuel system. Remove the fuel line fittings from the old fuel system. Install these parts in the same location on the new fuel system.3. Locate the engine serial number and write it down. Make reference to the Fuel Setting Information or Fuel System and Related Information to find the part number of the governor high idle spring that is needed for the engine. The same part number governor high idle spring given in the Fuel Setting Information, or the Fuel System and Related Information must be installed in the new service pump group. The 9L6508 High Idle Spring is already installed in the service pump and governor groups. The governor high idle spring needs to be changed only if the needed part number is different than 9L6508. If it is necessary to change the high idle spring, refer to the Service Manual. The part number of the low idle spring is 4N5663 and is the same for all fuel systems.4. A 4N0527 Overfueling Spring is installed in the service pump and governor groups. Refer to the Parts Manual to determine which overfueling spring is required. If the overfueling spring must be changed, refer to the Service Manual for the procedure.5. The 6N0509 Torque Control Group is already installed in each fuel injection pump and governor service group. Refer to the Parts Manual to find the torque control group that is needed according to engine application. Refer to the Engine Information Plate for the fuel setting dimension. If there is no information plate, see either the Fuel Setting Information microfiche, or the Fuel System and Related Information microfiche. 6. If the torque control group must be changed, remove cover (2) and torque control group (3) from the old fuel system. Remove the similar parts from the new fuel system. Install the torque control group from the old fuel system on the new fuel system. Be sure the fuel system has a Full Load Stop Pin. Refer to Examples of Torque Control Groups

Removal and Installation

1. Remove the pump and governor from the engine. Refer to the Service Manual.

When a replacement fuel injection pump and governor is installed on an engine (or when replacement parts are put in a fuel injection pump and governor), use the information on the engine information plate and always check engine low idle speed, set point and the fuel setting dimension. These settings and dimensions must be checked and adjustments made by a mechanic that has the necessary training in fuel system maintenance. Before the fuel system checks and adjustment are made, remove the original factory fuel system seal. After all fuel system work has been completed, install your Dealer seal as a replacement seal. Refer to Fuel System and Related Information or Fuel Setting Information for additional specifications.

2. Put the new service pump group in a 2P8315 Bracket Assembly (1) so it will be easier to work on. Remove the shut-off solenoid and the solenoid ground wire from the old fuel system. Remove the fuel line fittings from the old fuel system. Install these parts in the same location on the new fuel system.3. Locate the engine serial number and write it down. Make reference to the Fuel Setting Information or Fuel System and Related Information to find the part number of the governor high idle spring that is needed for the engine. The same part number governor high idle spring given in the Fuel Setting Information, or the Fuel System and Related Information must be installed in the new service pump group. The 9L6508 High Idle Spring is already installed in the service pump and governor groups. The governor high idle spring needs to be changed only if the needed part number is different than 9L6508. If it is necessary to change the high idle spring, refer to the Service Manual. The part number of the low idle spring is 4N5663 and is the same for all fuel systems.4. A 4N0527 Overfueling Spring is installed in the service pump and governor groups. Refer to the Parts Manual to determine which overfueling spring is required. If the overfueling spring must be changed, refer to the Service Manual for the procedure.5. The 6N0509 Torque Control Group is already installed in each fuel injection pump and governor service group. Refer to the Parts Manual to find the torque control group that is needed according to engine application. Refer to the Engine Information Plate for the fuel setting dimension. If there is no information plate, see either the Fuel Setting Information microfiche, or the Fuel System and Related Information microfiche. 6. If the torque control group must be changed, remove cover (2) and torque control group (3) from the old fuel system. Remove the similar parts from the new fuel system. Install the torque control group from the old fuel system on the new fuel system. Be sure the fuel system has a Full Load Stop Pin. Refer to Examples of Torque Control Groups