Rating:

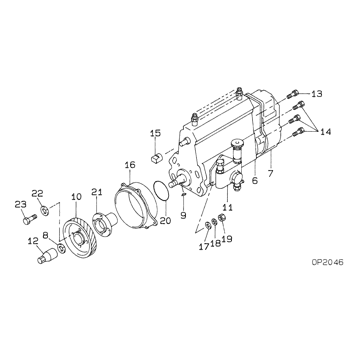

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

Construction machine 4M40

Engine

4M40

Serial start-end

0003-

Info

Injector Nozzle

093500-6900

Injector nozzle:

0935006900

KIT List:

Part name

Kit1

Kit2

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

09300-06590

PUMP ASSY, INJECTI

Information:

Start By:a. remove oil panb. remove underframe 1. Remove bolts (1) that hold main bearing cap (2) in place and remove main cap (2).2. Remove the bearing half from the cap.

If the crankshaft is turned in the wrong direction, the tab of the bearing will be pushed between the crankshaft and cylinder block. This can cause damage to either or both the crankshaft and block.

3. Remove the upper half of main bearings (3) as follows:a. Turn the crankshaft until tool (A) can be installed in the crankshaft journal. Install tool (A).b. Turn the crankshaft in the direction which will push the upper main bearing out, tab end first.c. Check the condition of the bearings. (See Guideline For Reusable Parts, Main And Connecting Rod Bearings, Form No. SEBF8009 and SEBD0531). The following steps are for the installation of the crankshaft main bearings. Put clean engine oil on the main bearings for the assembly. Also, be sure the tabs on the back side of the main bearings fit in the grooves of the main bearing caps and cylinder block. Take care to insure that the bearings are installed in the correct locations. Two different part numbers are used in quantities of three and four. The part number having the quantity of four is to be installed on crank main bearings 2, 3, 5 and 6. The part number having the quantity of three is to be installed on crank bearing 1, 4 and 7.4. Clean the surfaces in the cylinder block for the main bearings. Use tool (A), and install new upper halves of main bearing (bearings with the oil hole) in the cylinder block. Do not put oil on the back of the bearing.5. Clean the surface of the main bearing caps for the main bearings. Install the lower halves of the main bearings in the main caps. Do not put oil on the back of the bearing. Main bearing caps should be installed with the part number towards the right side. Caps are to be identified by stamped number 1 thru 7 located on the bottom unmachined surface.6. Put main bearing caps (2) in position on the cylinder block. Put engine oil or molylube on the bolt threads and the washer face, then install the bolts. Tighten the bolts on the side where the main bearing tabs are located to a torque of 95 5 N m (70 4 lb ft). Tighten the bolts on the opposite side to a torque of 95 5 N m (70 4 lb ft).7. Put a mark on each bolt head and the bearing caps. Turn the bolts that are opposite the main bearing tabs an additional 90° 5° turn. Then turn the bolts on the side where the main bearing tabs are located an additional 90° 5° turn.

Typical Example8. Check the end play of the crankshaft with a dial indicator and magnetic base. The end play must be 0.1 to 0.5 mm (.004 to .020

If the crankshaft is turned in the wrong direction, the tab of the bearing will be pushed between the crankshaft and cylinder block. This can cause damage to either or both the crankshaft and block.

3. Remove the upper half of main bearings (3) as follows:a. Turn the crankshaft until tool (A) can be installed in the crankshaft journal. Install tool (A).b. Turn the crankshaft in the direction which will push the upper main bearing out, tab end first.c. Check the condition of the bearings. (See Guideline For Reusable Parts, Main And Connecting Rod Bearings, Form No. SEBF8009 and SEBD0531). The following steps are for the installation of the crankshaft main bearings. Put clean engine oil on the main bearings for the assembly. Also, be sure the tabs on the back side of the main bearings fit in the grooves of the main bearing caps and cylinder block. Take care to insure that the bearings are installed in the correct locations. Two different part numbers are used in quantities of three and four. The part number having the quantity of four is to be installed on crank main bearings 2, 3, 5 and 6. The part number having the quantity of three is to be installed on crank bearing 1, 4 and 7.4. Clean the surfaces in the cylinder block for the main bearings. Use tool (A), and install new upper halves of main bearing (bearings with the oil hole) in the cylinder block. Do not put oil on the back of the bearing.5. Clean the surface of the main bearing caps for the main bearings. Install the lower halves of the main bearings in the main caps. Do not put oil on the back of the bearing. Main bearing caps should be installed with the part number towards the right side. Caps are to be identified by stamped number 1 thru 7 located on the bottom unmachined surface.6. Put main bearing caps (2) in position on the cylinder block. Put engine oil or molylube on the bolt threads and the washer face, then install the bolts. Tighten the bolts on the side where the main bearing tabs are located to a torque of 95 5 N m (70 4 lb ft). Tighten the bolts on the opposite side to a torque of 95 5 N m (70 4 lb ft).7. Put a mark on each bolt head and the bearing caps. Turn the bolts that are opposite the main bearing tabs an additional 90° 5° turn. Then turn the bolts on the side where the main bearing tabs are located an additional 90° 5° turn.

Typical Example8. Check the end play of the crankshaft with a dial indicator and magnetic base. The end play must be 0.1 to 0.5 mm (.004 to .020