Rating:

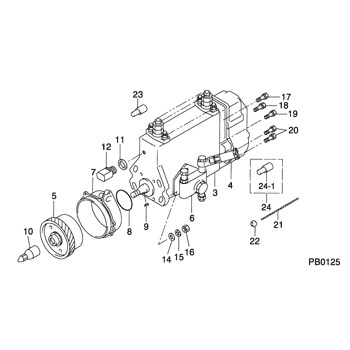

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

BUS D4AL

Engine

D4AL

Serial start-end

0005-

Info

Injector Nozzle

093500-7030

Injector nozzle:

0935007030

KIT List:

Part name

Kit1

Kit2

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

09300-06580

PUMP ASSY, INJECTI

Information:

P-500: Inspecting Electrical Connectors

Many of the Operational Procedures and Diagnostic Code Procedures in this troubleshooting guide will direct you to check a specific electrical connector. Use the following steps to help determine if the connector is the cause of the problem. If a problem is found in the electrical connector, repair the connector and continue the test procedure.1. Check Connector Lock Ring Or Allen Screw. Make sure that the connector is properly locked and that the lock ring or allen screw (4mm) is capable of locking the connector together.2. Perform 10 Pound Pull Test On Each Pin/Wire. Each pin and connector should easily withstand 10 pounds of pull, and remain in the connector body. This test checks whether the wire was properly crimped in the pin, and whether the pin was properly inserted into the connector. Repair as needed. Pins should ALWAYS be crimped onto the wires; NEVER soldered.3. Visually Inspect Wiring. Look for worn or abraded wires. Check for pinched or damaged harnesses.4. Visually Inspect Connectors. Verify that pins and sockets are not corroded or damaged. Verify proper alignment and location of pins in the connector.5. Check Individual Pins And Sockets. This is especially important for intermittent problems. Using a new pin, insert the pin into each socket one at a time to check for a good grip on the pin by the socket. Repeat for each pin on the mating side of the connector, using a new socket for the test. P-501: Electrical Power Supply To PEEC III

System Operation

The PEEC III ECM receives electrical power (battery voltage) through wiring supplied by the vehicle manufacturer. In typical applications, PEEC III receives power whenever the key is turned on.Some vehicles may be equipped with an engine protection shutdown system or an idle timer shutdown system (external to PEEC III) that interrupts electrical power to the ECM to shut down the engine. Some of these will not supply power to PEEC III until the engine is cranked, until oil pressure comes up to acceptable limits, or until an override button is pressed. Keep in mind that these devices may be the cause of intermittent power to the ECM.This procedure tests whether proper voltage is being supplied by vehicle wiring.For intermittent problems that could be caused by vehicle wiring (such as intermittent shutdowns) temporarily bypassing the vehicle wiring may be an effective means of determining the root cause. If symptoms vanish with the wiring bypassed, vehicle wiring was the cause. A means of bypassing vehicle wiring is explained in step 4 of the functional test. Schematic

Diagnostic Codes

Functional Test

Figure 3P-502: Throttle Position Sensor

System Operation

The throttle position sensor is used to provide a throttle signal to the ECM. Sensor output is a constant frequency signal with a pulse width that varies with throttle position. This output signal is referred to as either "Duty Cycle" or "Pulse Width Modulated" (PWM) signal and is expressed as a percentage between 0 and 100%.The throttle position sensor may be one of two types. The "remote mounted"

Many of the Operational Procedures and Diagnostic Code Procedures in this troubleshooting guide will direct you to check a specific electrical connector. Use the following steps to help determine if the connector is the cause of the problem. If a problem is found in the electrical connector, repair the connector and continue the test procedure.1. Check Connector Lock Ring Or Allen Screw. Make sure that the connector is properly locked and that the lock ring or allen screw (4mm) is capable of locking the connector together.2. Perform 10 Pound Pull Test On Each Pin/Wire. Each pin and connector should easily withstand 10 pounds of pull, and remain in the connector body. This test checks whether the wire was properly crimped in the pin, and whether the pin was properly inserted into the connector. Repair as needed. Pins should ALWAYS be crimped onto the wires; NEVER soldered.3. Visually Inspect Wiring. Look for worn or abraded wires. Check for pinched or damaged harnesses.4. Visually Inspect Connectors. Verify that pins and sockets are not corroded or damaged. Verify proper alignment and location of pins in the connector.5. Check Individual Pins And Sockets. This is especially important for intermittent problems. Using a new pin, insert the pin into each socket one at a time to check for a good grip on the pin by the socket. Repeat for each pin on the mating side of the connector, using a new socket for the test. P-501: Electrical Power Supply To PEEC III

System Operation

The PEEC III ECM receives electrical power (battery voltage) through wiring supplied by the vehicle manufacturer. In typical applications, PEEC III receives power whenever the key is turned on.Some vehicles may be equipped with an engine protection shutdown system or an idle timer shutdown system (external to PEEC III) that interrupts electrical power to the ECM to shut down the engine. Some of these will not supply power to PEEC III until the engine is cranked, until oil pressure comes up to acceptable limits, or until an override button is pressed. Keep in mind that these devices may be the cause of intermittent power to the ECM.This procedure tests whether proper voltage is being supplied by vehicle wiring.For intermittent problems that could be caused by vehicle wiring (such as intermittent shutdowns) temporarily bypassing the vehicle wiring may be an effective means of determining the root cause. If symptoms vanish with the wiring bypassed, vehicle wiring was the cause. A means of bypassing vehicle wiring is explained in step 4 of the functional test. Schematic

Diagnostic Codes

Functional Test

Figure 3P-502: Throttle Position Sensor

System Operation

The throttle position sensor is used to provide a throttle signal to the ECM. Sensor output is a constant frequency signal with a pulse width that varies with throttle position. This output signal is referred to as either "Duty Cycle" or "Pulse Width Modulated" (PWM) signal and is expressed as a percentage between 0 and 100%.The throttle position sensor may be one of two types. The "remote mounted"