Rating:

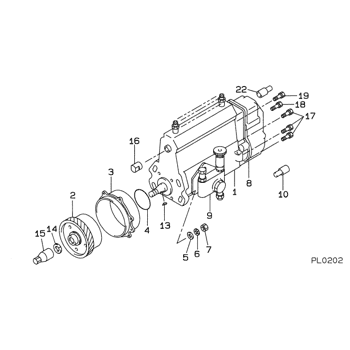

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

BUS 4D32

Engine

4D32

Serial start-end

8910--9310

Info

Injector Nozzle

093500-4490

Injector nozzle:

0935004490

KIT List:

Part name

Kit1

Kit2

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09300-04340

ME016938

PUMP ASSY, INJECTI

0930004340

ME016938

MITSUBISHI

PUMP ASSY, INJECTI

Information:

Introduction

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.If the crankshaft, gear case and/or crank gear are replaced, it is necessary to calibrate the injection timing. The following steps show how to calculate/determine the new injection timing by measuring angular deviation between the crankshaft TDC and Crank Position sensor detected TDC.Note: Once complete the engine ecm must be reprogrammed with the new injection timing value.Follow all steps.Procedure

Illustration 1 g06220548

(1) TC Mark (Flywheel Housing)

(2) TC Mark (Flywheel)

Remove valve cover, and injector and rocker arm. Bring the piston of cylinder 4 to TDC.

Illustration 2 g06220554

(3) Dial Gauge

(4) Valve

(5) O-ring

Remove the #4 exhaust valve bridge arm and valve spring. Insert a small O-ring (5) so the valve does not fall into the cylinder.

Set dial gauge (3) on the tip of the valve (4).

Illustration 3 g06220569

(6) Tri - Square

(7) Flywheel Housing

(8) Flywheel

Illustration 4 g06220573

(7) Flywheel Housing

(8) Flywheel

(9) Reference Line

Turn the flywheel counterclockwise and measure the position where the tip of the valve is the highest.

Stop the flywheel at the position where the tip of the valve is the highest. Put a tri - square (6)

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.If the crankshaft, gear case and/or crank gear are replaced, it is necessary to calibrate the injection timing. The following steps show how to calculate/determine the new injection timing by measuring angular deviation between the crankshaft TDC and Crank Position sensor detected TDC.Note: Once complete the engine ecm must be reprogrammed with the new injection timing value.Follow all steps.Procedure

Illustration 1 g06220548

(1) TC Mark (Flywheel Housing)

(2) TC Mark (Flywheel)

Remove valve cover, and injector and rocker arm. Bring the piston of cylinder 4 to TDC.

Illustration 2 g06220554

(3) Dial Gauge

(4) Valve

(5) O-ring

Remove the #4 exhaust valve bridge arm and valve spring. Insert a small O-ring (5) so the valve does not fall into the cylinder.

Set dial gauge (3) on the tip of the valve (4).

Illustration 3 g06220569

(6) Tri - Square

(7) Flywheel Housing

(8) Flywheel

Illustration 4 g06220573

(7) Flywheel Housing

(8) Flywheel

(9) Reference Line

Turn the flywheel counterclockwise and measure the position where the tip of the valve is the highest.

Stop the flywheel at the position where the tip of the valve is the highest. Put a tri - square (6)