Rating:

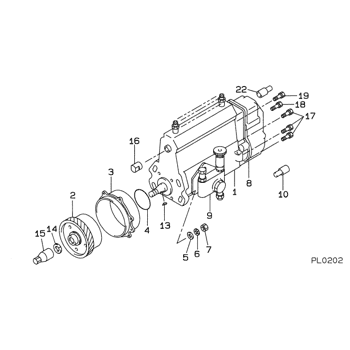

Information pump assy, injecti Denso

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09300-04131

PUMP ASSY, INJECTI

9309-

ME016796

MITSUBISHI

Include in ##:

09300-04131

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09300-04131

ME016796

PUMP ASSY, INJECTI

Test Calibration Data:

0930004130

ME016796

0930004131

ME016796

Information:

Introduction

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.DEF injectors are being replaced in the field and returned to Caterpillar for testing. Results of the testing are finding a large portion of the returned DEF injectors are found to be fault not repeated.This form is to be used and filled out in any case that a DEF injector is being replaced.The DEF injector troubleshooting return form needs to be completed and included within failed part returns documenting what was found that led to DEF injector replacement. Attach the photos of DEF injector tip and mount area along with a Product Status Report to the SIMS claim.References

Table 1

Engine Publication Type Media Number

C7.1 Troubleshooting UENR0668

Testing and Adjusting UENR4467

Disassembly and Assembly UENR4468

C9.3 Troubleshooting UENR0978

Testing and Adjusting UENR3402

Disassembly and Assembly UENR0130

C13 Troubleshooting UENR0955

Testing and Adjusting UENR4302

Disassembly and Assembly UENR0131

C15/C18 Troubleshooting UENR0955

Testing and Adjusting UENR3351

Disassembly and Assembly UENR0132 Procedure

What code are you troubleshooting? __________

Follow the correct troubleshooting procedure. Reference Table 1 for correct media number to use.

When troubleshooting procedure requests the DEF quality check, DEF injector resistance measurement, or Dosing Accuracy Test, document those results in Tables 2, 3, and 4.Tables

Table 2

DEF Quality Results

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting procedure for "Diesel Exhaust Fluid Quality - Test"

2 DEF Contamination Test Pass / Fail

3 DEF Concentration Test % at 20° C (68° F)

Illustration 1 g06175415

Table 3

Injector Resistance Measurement

Step Instruction Completed (Yes/No) Result Comments Units

1 Turn the keyswitch to the OFF position. Allow 2 minutes to elapse before proceeding.

2 Disconnect the DEF injectors from the applicable harness.

3 Inspect the connector for damage and debris.

4 Measure the temperature of the injector (aluminum body).

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.DEF injectors are being replaced in the field and returned to Caterpillar for testing. Results of the testing are finding a large portion of the returned DEF injectors are found to be fault not repeated.This form is to be used and filled out in any case that a DEF injector is being replaced.The DEF injector troubleshooting return form needs to be completed and included within failed part returns documenting what was found that led to DEF injector replacement. Attach the photos of DEF injector tip and mount area along with a Product Status Report to the SIMS claim.References

Table 1

Engine Publication Type Media Number

C7.1 Troubleshooting UENR0668

Testing and Adjusting UENR4467

Disassembly and Assembly UENR4468

C9.3 Troubleshooting UENR0978

Testing and Adjusting UENR3402

Disassembly and Assembly UENR0130

C13 Troubleshooting UENR0955

Testing and Adjusting UENR4302

Disassembly and Assembly UENR0131

C15/C18 Troubleshooting UENR0955

Testing and Adjusting UENR3351

Disassembly and Assembly UENR0132 Procedure

What code are you troubleshooting? __________

Follow the correct troubleshooting procedure. Reference Table 1 for correct media number to use.

When troubleshooting procedure requests the DEF quality check, DEF injector resistance measurement, or Dosing Accuracy Test, document those results in Tables 2, 3, and 4.Tables

Table 2

DEF Quality Results

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting procedure for "Diesel Exhaust Fluid Quality - Test"

2 DEF Contamination Test Pass / Fail

3 DEF Concentration Test % at 20° C (68° F)

Illustration 1 g06175415

Table 3

Injector Resistance Measurement

Step Instruction Completed (Yes/No) Result Comments Units

1 Turn the keyswitch to the OFF position. Allow 2 minutes to elapse before proceeding.

2 Disconnect the DEF injectors from the applicable harness.

3 Inspect the connector for damage and debris.

4 Measure the temperature of the injector (aluminum body).