Rating:

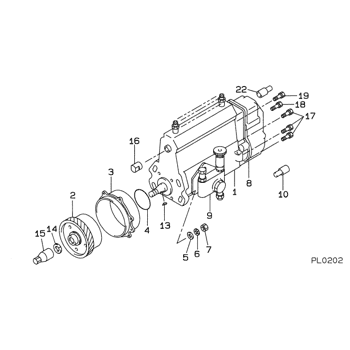

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL 4D31

Engine

4D31

Serial start-end

8409-

Info

Injector Nozzle

093500-2390

Injector nozzle:

0935002390

KIT List:

Part name

Kit1

Kit2

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

09300-00990

PUMP ASSY, INJECTI

Information:

Take care to avoid mixing metric and inch fasteners. Mismatched or incorrect fasteners can result in mechanical damage or malfunction, or possible personal injury. Original fasteners removed during disassembly should be saved for assembly when possible. If new ones are required, caution must be taken to replace with one that is of same part number and grade.Metric thread fasteners are identified by material strength (grade) numbers on bolt heads and nuts. Numbers on bolts will be 8.8, 10.9, etc. Numbers on nuts will be 8, 10, etc.Engine Design

Cylinder And Valve LocationBore ... 125.025 0.025 mm (4.9220 .0010 in)Stroke ... 140 mm (5.5 in)Displacement ... 10.3 liter (629 cu in)Cylinder Arrangement ... in-lineValves per Cylinder ... 4Valve Clearance Setting Intake ... 0.38 mm (.015 in)Exhaust ... 0.64 mm (.025 in)Compression Ratio ... 16 to 1, 16.25 to 1Type of Combustion ... Direct InjectionFiring Order: ... 1, 5, 3, 6, 2, 4Direction of Crankshaft Rotation (when seen from flywheel end) ... counterclockwise Front end of engine is opposite the flywheel end. Left side and right side of engine are as seen from flywheel end. No. 1 cylinder is the front cylinder.General Information

The engine is an electronically controlled mechanically actuated unit injector diesel engine. The engine is an inline 6 cylinder arrangement with a bore of 125.025 mm (4.9220 in) and a stroke of 140 mm (5.5 in) giving a total displacement of 10.3 liter (629 cu in). The engine as configured is for air to air aftercooling. It is a low profile arrangement with the exhaust and inlet manifolds on the right hand side.Several distinct design features follow:1. Two piece articulated piston with forged steel crown and forged aluminum skirt.2. Two piece cylinder block with cast iron crankcase and aluminum spacer block.3. Mid supported cylinder liner with high ring travel cooling.4. Siamese plenum intake ports.5. Oil pump bypass valve controlled by the engine oil manifold pressure.6. Temperature regulated oil inlet to the engine oil cooler.7. Bypass oil filter (an attachment).8. Helical gear fuel transfer pump.9. Engine braking retarder available.The electronic unit injector system eliminates many of the mechanical components of a "pump-in-line" system. It also provides increased control of timing and fuel/air ratio control. Timing advance is achieved by precise control of injector timing. Engine rpm is controlled by adjusting the injection duration. A special pulse wheel provides information to the electronic control module for detection of cylinder position and engine rpm.The engine has built-in diagnostics to insure that all components are operating properly. In the event of a system component failure, the operator will be alerted to the condition via the dashboard mounted "check engine" light. A Caterpillar service tool can be used to read the numerical code of the faulty component or condition, or the cruise control switches can be used to "flash" the code on the dash mounted "check engine" light. Intermittent faults are "logged" and stored in memory.Starting The Engine

The 3176 ECM will automatically provide the correct amount of fuel to start

Cylinder And Valve LocationBore ... 125.025 0.025 mm (4.9220 .0010 in)Stroke ... 140 mm (5.5 in)Displacement ... 10.3 liter (629 cu in)Cylinder Arrangement ... in-lineValves per Cylinder ... 4Valve Clearance Setting Intake ... 0.38 mm (.015 in)Exhaust ... 0.64 mm (.025 in)Compression Ratio ... 16 to 1, 16.25 to 1Type of Combustion ... Direct InjectionFiring Order: ... 1, 5, 3, 6, 2, 4Direction of Crankshaft Rotation (when seen from flywheel end) ... counterclockwise Front end of engine is opposite the flywheel end. Left side and right side of engine are as seen from flywheel end. No. 1 cylinder is the front cylinder.General Information

The engine is an electronically controlled mechanically actuated unit injector diesel engine. The engine is an inline 6 cylinder arrangement with a bore of 125.025 mm (4.9220 in) and a stroke of 140 mm (5.5 in) giving a total displacement of 10.3 liter (629 cu in). The engine as configured is for air to air aftercooling. It is a low profile arrangement with the exhaust and inlet manifolds on the right hand side.Several distinct design features follow:1. Two piece articulated piston with forged steel crown and forged aluminum skirt.2. Two piece cylinder block with cast iron crankcase and aluminum spacer block.3. Mid supported cylinder liner with high ring travel cooling.4. Siamese plenum intake ports.5. Oil pump bypass valve controlled by the engine oil manifold pressure.6. Temperature regulated oil inlet to the engine oil cooler.7. Bypass oil filter (an attachment).8. Helical gear fuel transfer pump.9. Engine braking retarder available.The electronic unit injector system eliminates many of the mechanical components of a "pump-in-line" system. It also provides increased control of timing and fuel/air ratio control. Timing advance is achieved by precise control of injector timing. Engine rpm is controlled by adjusting the injection duration. A special pulse wheel provides information to the electronic control module for detection of cylinder position and engine rpm.The engine has built-in diagnostics to insure that all components are operating properly. In the event of a system component failure, the operator will be alerted to the condition via the dashboard mounted "check engine" light. A Caterpillar service tool can be used to read the numerical code of the faulty component or condition, or the cruise control switches can be used to "flash" the code on the dash mounted "check engine" light. Intermittent faults are "logged" and stored in memory.Starting The Engine

The 3176 ECM will automatically provide the correct amount of fuel to start