Rating:

Information pump assy, fuel fe Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Hacus - Forklift FPE253240 Feed Pump S4S S6S Hacus Aftermarket - New

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09210-00561

PUMP ASSY, FUEL FE

KS

000

[01]

09210-00561

PUMP ASSY, FUEL FE

KS

000

[01]

09210-00561

PUMP ASSY, FUEL FE

KS

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09210-00561

PUMP ASSY, FUEL FE

Information:

2. Loosen clamp (1).3. Remove two bolts (2).4. Remove two bolts (3) and washers.5. Remove water pump (4) and the gasket. When installing replace the gasket. Make sure all gasket surfaces are clean and free of dirt. For installation of the water pump, reverse the removal steps.6. Fill the radiator with coolant to the proper level. See the Operation & Maintenance Manual.Disassemble & Assemble Water Pump

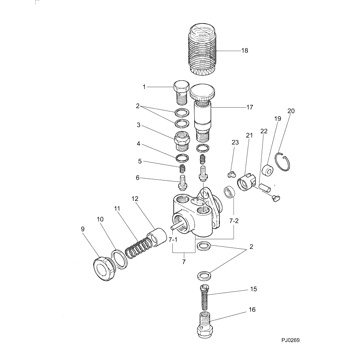

The following tools are needed for disassembly. Start By:a. remove water pump 1. Remove bolt (15) and the washer. Remove bearing (12) and gear (10) as a unit.2. Use Tool (A), (C) and a press, and remove bearing (12) from gear (10).3. Remove snap ring (8) with Tool (B).4. Remove two bolts (1), the washers, cover (14) and gasket (2) from water pump housing (18).5. Loosen bolt (13) approximately 6.4 mm (.25 in). Hit the bolt with a soft hammer to loosen impeller (16) from shaft (9).6. Remove bolt (13), washer (11), impeller (16), spring (3) and seal assembly (4) from shaft (9).7. Remove bearing (7) and shaft (9) as a unit.8. Use Tool (A), (C) and a press to remove bearing (7) from shaft (9).9. Remove ceramic seal (5) and seal (17) from water pump housing (18).10. Use Tool (C) to remove lip-type seal (6) from the water pump housing. The following steps are for assembly of the water pump. The following tools are needed for assembly. 11. Install lip-type seal (6) in water pump housing (18) with Tool (C). The lip of the seal must be toward the bearings. Put clean engine oil on the lip of the seal.12. Install shaft (9) in bearing (7) with a press.13. Install shaft (9) and bearing (7) as a unit in water pump housing (18).14. Install snap ring (8) with Tool (B).

Clean water only is permitted for use as a lubricant for assembly. Do not damage or put hands on the wear surface of the carbon ring or the ceramic ring. Install the ceramic ring with the smoothest face of the ring toward the carbon seal assembly.

15. Put ceramic ring (5) in position in seal (17). Use hand pressure and Tool (D) to install the ceramic ring.16. Remove spring (3) from seal assembly (4). Use hand pressure and Tool (D) to install the seal assembly. Push seal assembly (4) on shaft (9) until it makes light contact with ceramic ring (5).17. Install spring (3) on seal assembly (4). Put impeller (16) in position on shaft (9), and install washer (11) and bolt (13) that hold it. Tighten bolt (13) to a torque of 38.0 1.5 N m (28 1 lb ft).18. Put gasket (2) and cover (14) in position on water pump housing (18). Install the two washers and bolts (1) that hold them.19. Install bearing (12) on gear (10) with a press.20. Position gear (10) and bearing (12) as a unit on shaft (9). Install the washer and bolt (15) that hold them together. Tighten bolt (15) to a torque of

The following tools are needed for disassembly. Start By:a. remove water pump 1. Remove bolt (15) and the washer. Remove bearing (12) and gear (10) as a unit.2. Use Tool (A), (C) and a press, and remove bearing (12) from gear (10).3. Remove snap ring (8) with Tool (B).4. Remove two bolts (1), the washers, cover (14) and gasket (2) from water pump housing (18).5. Loosen bolt (13) approximately 6.4 mm (.25 in). Hit the bolt with a soft hammer to loosen impeller (16) from shaft (9).6. Remove bolt (13), washer (11), impeller (16), spring (3) and seal assembly (4) from shaft (9).7. Remove bearing (7) and shaft (9) as a unit.8. Use Tool (A), (C) and a press to remove bearing (7) from shaft (9).9. Remove ceramic seal (5) and seal (17) from water pump housing (18).10. Use Tool (C) to remove lip-type seal (6) from the water pump housing. The following steps are for assembly of the water pump. The following tools are needed for assembly. 11. Install lip-type seal (6) in water pump housing (18) with Tool (C). The lip of the seal must be toward the bearings. Put clean engine oil on the lip of the seal.12. Install shaft (9) in bearing (7) with a press.13. Install shaft (9) and bearing (7) as a unit in water pump housing (18).14. Install snap ring (8) with Tool (B).

Clean water only is permitted for use as a lubricant for assembly. Do not damage or put hands on the wear surface of the carbon ring or the ceramic ring. Install the ceramic ring with the smoothest face of the ring toward the carbon seal assembly.

15. Put ceramic ring (5) in position in seal (17). Use hand pressure and Tool (D) to install the ceramic ring.16. Remove spring (3) from seal assembly (4). Use hand pressure and Tool (D) to install the seal assembly. Push seal assembly (4) on shaft (9) until it makes light contact with ceramic ring (5).17. Install spring (3) on seal assembly (4). Put impeller (16) in position on shaft (9), and install washer (11) and bolt (13) that hold it. Tighten bolt (13) to a torque of 38.0 1.5 N m (28 1 lb ft).18. Put gasket (2) and cover (14) in position on water pump housing (18). Install the two washers and bolts (1) that hold them.19. Install bearing (12) on gear (10) with a press.20. Position gear (10) and bearing (12) as a unit on shaft (9). Install the washer and bolt (15) that hold them together. Tighten bolt (15) to a torque of