Rating:

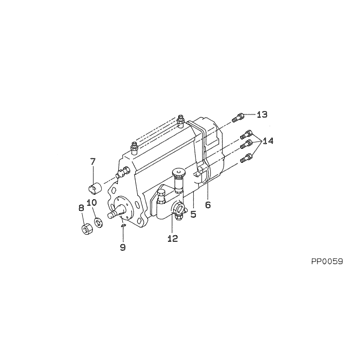

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL S4S-DT

Engine

S4S-DT

Serial start-end

0701-

Info

Injector Nozzle

093500-7600

Injector nozzle:

0935007600

KIT List:

Part name

Kit1

Kit2

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09200-05620

PUMP ASSY, INJECTI

A4,RSV

Include in ##:

09200-05620

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09200-05620

PUMP ASSY, INJECTI

Information:

Start By:a. remove engine and transmissionb. remove oil pumpc. remove crankshaft rear seal 1. Fasten the engine to tool (A) at the flywheel end as shown.2. Remove bridge (1) and the seals. 3. Remove rear main bearing cap (2). Be sure the location is marked on the main bearing cap before it is removed. The stamped location number is toward the camshaft. 4. Remove upper bearing half (3) with an approved bearing removal tool.

Do not turn the crankshaft in a counterclockwise direction because the tab of the bearing can be pushed between the crankshaft and the engine block. This will cause damage to the crankshaft and engine block.

5. Turn the crankshaft clockwise, as seen from the flywheel, to remove bearing upper half (3). 6. Remove bearing lower half (4) from rear main bearing cap (2). 7. Put the bearing upper half (3) in position on the crankshaft, and use the removal tool to rotate the bearing into position. Turn the crankshaft in a counterclockwise direction to engage bearing tab with the engine block. 8. Install the bearing lower half in the main bearing cap.9. Put a piece of Plastigage (5) across the crankshaft main bearing face. Install main bearings dry when the clearance checks are made. Put clean engine oil on the main bearings for final assembly.10. Put the main bearing cap in position. Put clean engine oil on the threads of the main bearing cap bolts, and tighten them finger tight.11. Tighten the main bearing cap bolts to a torque

Do not turn the crankshaft in a counterclockwise direction because the tab of the bearing can be pushed between the crankshaft and the engine block. This will cause damage to the crankshaft and engine block.

5. Turn the crankshaft clockwise, as seen from the flywheel, to remove bearing upper half (3). 6. Remove bearing lower half (4) from rear main bearing cap (2). 7. Put the bearing upper half (3) in position on the crankshaft, and use the removal tool to rotate the bearing into position. Turn the crankshaft in a counterclockwise direction to engage bearing tab with the engine block. 8. Install the bearing lower half in the main bearing cap.9. Put a piece of Plastigage (5) across the crankshaft main bearing face. Install main bearings dry when the clearance checks are made. Put clean engine oil on the main bearings for final assembly.10. Put the main bearing cap in position. Put clean engine oil on the threads of the main bearing cap bolts, and tighten them finger tight.11. Tighten the main bearing cap bolts to a torque