Rating:

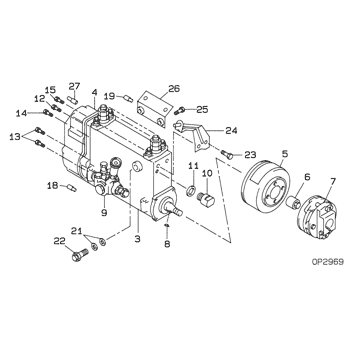

Information pump assy, injecti Denso

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09200-02054

PUMP ASSY, INJECTI

NB6,R901

22010-7740

HINO

000

[01]

09200-02054

PUMP ASSY, INJECTI

NB6,R901

S2201-07740

HINO

Include in ##:

09200-02054

as PUMP ASSY, INJECTI

09200-02054 PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09200-02054

22010-7740

PUMP ASSY, INJECTI

Test Calibration Data:

0920002050

22010-7740

0920002051

22010-7740

0920002052

22010-7740

0920002053

22010-7740

0920002054

22010-7740

Information:

03Dec2012

(Revised 05Dec2012)

U-644

After Failure Only

PRODUCT SUPPORT PROGRAM FOR REPLACING THE ELECTRONIC UNIT INJECTORS ON CERTAIN 993K WHEEL LOADERS

1290 1251 1254 1713 PS52346

This Program can only be administered after a failure occurs.The decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS52346" as the Part Numberand "7755" as the Group Number. Use "96" as the Warranty Claim Description Code and use "Z" as the SIMS Description Code.

The information supplied in this service letter may not be valid after the termination date of this program.Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

This Revised Service Letter replaces the 03Dec2012 (Revised 03Dec2012) Service Letter. Changes have been made to the Action Required.

TERMINATION DATE

31Dec2014

PROBLEM

The existing fuel injectors can experience injector failures due to injector body cracking. If the existing injector fails it can result in complaints of high oil levels due to excessive fuel dilution.

AFFECTED PRODUCT

Model Identification Number

993K Z4D00179-00182

PARTS NEEDED

Qty

Part Number Description

2 1R1808 FILTER-LUBE

12 8S9191 BOLT

4 3460335 CLAMP-BAND

12 3594060 INJECTOR GP-FUEL

1 BULK_OIL DEO-ULS (120 Liters)

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 2% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

If excessive fuel dilution of engine oil is found reference the following to determine the cause of fuel dilution.

Special Instruction, REHS3007,"Determining the Cause of Fuel Dilution of Engine Oil"

Troubleshooting, KENR9795, "C27 and C32 Engines for Caterpillar Built Machines"

Once an injector(s) has been identified as having a cracked/leaking injector body, replace the failed injector(s). Inspect the remaining good injector serial numbers with Cat ET, (Injector Serial Numbers = Injector trim file name, (ie 6Cxxxxxxxxxx.trm)). If the remaining injector serial numbers fall within the serial number range below, replace at the same time. Refer to Image 1 for the serial number location on the top of the electronic unit injector.

Injector Serial Numbers

6C001793971D through 6C002198297C

If an injector failure occurs on either of the rear two cylinders (right and/or left hand bank) the exhaust piping going from the turbo to the CEM will have to be removed. 346-0335 Exhaust Clamp cannot be reused and MUST be replaced with a new clamp. Refer to REHS5014, "Reuse Guideline for the Flexible Exhaust Pipe Group on Tier 4 Engines" for the proper installation and removal procedure. Refer to Image 2 for clamp location.

The 8S-9191 Injector Hold Down Bolts must be replaced.

Refer to Disassembly and Assembly, RENR9217 for the removal, installation, and tightening procedures.

After the engine is reassembled, change the engine oil and filters.