Rating:

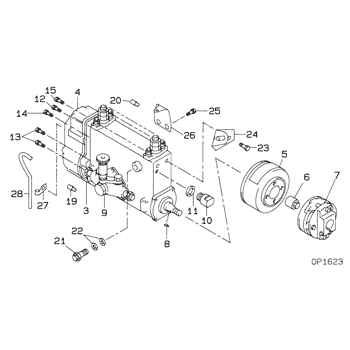

Information pump assy, injecti Denso

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09200-01985

PUMP ASSY, INJECTI

NB4,R801

22010-7773

HINO

000

[01]

09200-01985

PUMP ASSY, INJECTI

NB4,R801

S2201-07773

HINO

Include in ##:

09200-01985

as PUMP ASSY, INJECTI

09200-01985 PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09200-01985

22010-7773

PUMP ASSY, INJECTI

Information:

Inspecting and Adjusting Valve Clearance

The valve clearances should be inspected and adjusted when the engine is cold.Unit: mm (in.)

Adjusting valve clearance(1) Inspecting Valve Clearance

(a) Inspect each cylinder's valve clearance with the piston at the top-dead-center (TDC) position of its compression stroke. Follow the firing order, bringing the pistons to the TDC positions of their respective compression strokes by turning the crankshaft in the forward direction in increments of 180°.(2) Confirming Compression-Stroke TDC Position

(a) Bring piston No. 1 to the TDC position of its compression stroke. To do this, align the TDC mark on the crankshaft pulley with the mark on the gear case.(b) To confirm the compression-stroke TDC position, turn the crankshaft by approximately 20° in the forward and reverse directions and check for rocker-arm movement. When there is no rocker-arm movement, the piston is at the compression-stroke TDC position.(c) If rocker-arm movement occurs, the piston is at the TDC position of its intake or exhaust stroke. Give the crankshaft one more 180° turn to bring the piston to the TDC position of its compression stroke.(d) Start bringing the piston to the TDC position with cylinder No. 1 for inspection/adjustment of the valve clearance. Then, proceed to the other cylinder's pistons in accordance with the firing order. After cylinder No. 1, bring the piston in the next cylinder to its compression-stroke TDC position by turning the crankshaft in the forward direction (clockwise as seen from the timing gear case) by 180°. Finder orderCylinder Number: 1 - 3 - 4 - 2

Timing marks

Before starting the engine, place the timing gears in their original positions.

(3) Adjusting Valve Clearance

(a) Loosen the rocker arm nut, then adjust the clearance to the standard value using the adjusting screw and a thickness gauge (1).(b) Hold the adjusting screw in position while tightening the nut.

Adjusting valve clearance

When adjusting the valve clearances following disassembly and reassembly, turn the crankshaft two or three times then check again that the clearance are within specification.

Bleeding Air From Fuel System

Air should be bled first from the fuel filter and then from the injection pump, i.e., starting at the position closer to the fuel tank.(1) With the system with an electromagnetic-plunger-type fuel pump, turn the key to the ON position to force fuel to flow. Then, loosen the air vent screw (1), allow air in the filter to be expelled, and retighten the screw.(2) Loosen air vent screws (2) and (3) on the injection pump in that sequence to bleed air from the fuel pipe and injection pump.(3) When air-bleeding from screws (2) and (3) is complete, retighten each screw.(4) Air in the injection pipes and nozzles will be expelled automatically when the engine is cranked.

Bleeding air from fuel systemInspecting and Adjusting Injection Timing

(1) Preparation for Inspection

(a) Close the cock on the fuel filter.(b) Remove the No. 1 injection pipe.(c) Remove the No. 1 delivery valve holder, deliver valve, and spring. Then, refit only the delivery valve holder.

Removing delivery valve and spring(d) Connect the injection pipe on the pump side only

The valve clearances should be inspected and adjusted when the engine is cold.Unit: mm (in.)

Adjusting valve clearance(1) Inspecting Valve Clearance

(a) Inspect each cylinder's valve clearance with the piston at the top-dead-center (TDC) position of its compression stroke. Follow the firing order, bringing the pistons to the TDC positions of their respective compression strokes by turning the crankshaft in the forward direction in increments of 180°.(2) Confirming Compression-Stroke TDC Position

(a) Bring piston No. 1 to the TDC position of its compression stroke. To do this, align the TDC mark on the crankshaft pulley with the mark on the gear case.(b) To confirm the compression-stroke TDC position, turn the crankshaft by approximately 20° in the forward and reverse directions and check for rocker-arm movement. When there is no rocker-arm movement, the piston is at the compression-stroke TDC position.(c) If rocker-arm movement occurs, the piston is at the TDC position of its intake or exhaust stroke. Give the crankshaft one more 180° turn to bring the piston to the TDC position of its compression stroke.(d) Start bringing the piston to the TDC position with cylinder No. 1 for inspection/adjustment of the valve clearance. Then, proceed to the other cylinder's pistons in accordance with the firing order. After cylinder No. 1, bring the piston in the next cylinder to its compression-stroke TDC position by turning the crankshaft in the forward direction (clockwise as seen from the timing gear case) by 180°. Finder orderCylinder Number: 1 - 3 - 4 - 2

Timing marks

Before starting the engine, place the timing gears in their original positions.

(3) Adjusting Valve Clearance

(a) Loosen the rocker arm nut, then adjust the clearance to the standard value using the adjusting screw and a thickness gauge (1).(b) Hold the adjusting screw in position while tightening the nut.

Adjusting valve clearance

When adjusting the valve clearances following disassembly and reassembly, turn the crankshaft two or three times then check again that the clearance are within specification.

Bleeding Air From Fuel System

Air should be bled first from the fuel filter and then from the injection pump, i.e., starting at the position closer to the fuel tank.(1) With the system with an electromagnetic-plunger-type fuel pump, turn the key to the ON position to force fuel to flow. Then, loosen the air vent screw (1), allow air in the filter to be expelled, and retighten the screw.(2) Loosen air vent screws (2) and (3) on the injection pump in that sequence to bleed air from the fuel pipe and injection pump.(3) When air-bleeding from screws (2) and (3) is complete, retighten each screw.(4) Air in the injection pipes and nozzles will be expelled automatically when the engine is cranked.

Bleeding air from fuel systemInspecting and Adjusting Injection Timing

(1) Preparation for Inspection

(a) Close the cock on the fuel filter.(b) Remove the No. 1 injection pipe.(c) Remove the No. 1 delivery valve holder, deliver valve, and spring. Then, refit only the delivery valve holder.

Removing delivery valve and spring(d) Connect the injection pipe on the pump side only