Rating:

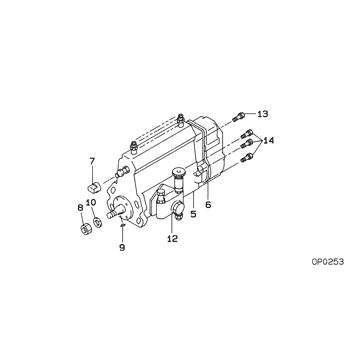

Information pump assy, injecti Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$4,064.50

23 Jan 2025

31.14[14.01] Pounds

Amazon.com

Hacus - Forklift FPE257997 Pump - Injector S6S Hacus Aftermarket - New

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09200-00781

PUMP ASSY, INJECTI

Information:

Caterpillar: Confidential Yellow

Termination Date

January 31, 1993Problem

The fuel injection pumps used on certain Remanufactured 1160 and 3208 Engines need to be inspected for gummy deposits.

Affected Product

Model & Identification Number

1160 (57V1-34325)

3208 (9WC1-730; 5CD1-5868; 62W1-68596; 93Z1-8374)

Remanufactured Fuel Pump Part Numbers

0R07660R09030R23840R23860R09020R23740R23850R2877 The above list of remanufactured pumps are affected only if they are stamped with a date code of 12/91 (UMDU) or earlier.

Parts Needed

Not Applicable

Action Required

Before installing or delivering any of the affected product, perform the following steps to ensure the internal fuel injection pump components are not stuck due to fuel pump gumming:

1. Remove the top cover of the fuel injection pump and check to ensure that all sleeves and levers are free and there are no gummy deposits on any of these components.2. If inspection performed in Step 1 indicates everything is clean, install top cover and return to parts stock.3. If inspection reveals components have gummy deposits, remove 12 ounces of fuel from the fuel pump housing and replace it with: - Fuel Injector Cleaner or

- Carburetor/Choke Cleaner

4. Allow the components to soak in cleaning solution for 45 minutes, then rotate the engine crankshaft to rotate the fuel injection pump (on pumps only, rotate the fuel pump camshaft). This will ensure the components have the gummy deposits removed. If the engine or fuel pump will be used immediately, install the cover on the fuel injection pump, and install or deliver the engine or pump.5. If the engine or fuel pump will be returned to stock, DO NOT leave the fuel injection pump full of cleaning solution because it may not contain any rust inhibitors. Remove the cleaning solution, fill the fuel injector pump with clean diesel fuel, and install the cover on the pump.Service Claim Allowances

It is a .5-hr. job to inspect the pump. An additional .5-hr. may be claimed if cleaning is required.

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Termination Date

January 31, 1993Problem

The fuel injection pumps used on certain Remanufactured 1160 and 3208 Engines need to be inspected for gummy deposits.

Affected Product

Model & Identification Number

1160 (57V1-34325)

3208 (9WC1-730; 5CD1-5868; 62W1-68596; 93Z1-8374)

Remanufactured Fuel Pump Part Numbers

0R07660R09030R23840R23860R09020R23740R23850R2877 The above list of remanufactured pumps are affected only if they are stamped with a date code of 12/91 (UMDU) or earlier.

Parts Needed

Not Applicable

Action Required

Before installing or delivering any of the affected product, perform the following steps to ensure the internal fuel injection pump components are not stuck due to fuel pump gumming:

1. Remove the top cover of the fuel injection pump and check to ensure that all sleeves and levers are free and there are no gummy deposits on any of these components.2. If inspection performed in Step 1 indicates everything is clean, install top cover and return to parts stock.3. If inspection reveals components have gummy deposits, remove 12 ounces of fuel from the fuel pump housing and replace it with: - Fuel Injector Cleaner or

- Carburetor/Choke Cleaner

4. Allow the components to soak in cleaning solution for 45 minutes, then rotate the engine crankshaft to rotate the fuel injection pump (on pumps only, rotate the fuel pump camshaft). This will ensure the components have the gummy deposits removed. If the engine or fuel pump will be used immediately, install the cover on the fuel injection pump, and install or deliver the engine or pump.5. If the engine or fuel pump will be returned to stock, DO NOT leave the fuel injection pump full of cleaning solution because it may not contain any rust inhibitors. Remove the cleaning solution, fill the fuel injector pump with clean diesel fuel, and install the cover on the pump.Service Claim Allowances

It is a .5-hr. job to inspect the pump. An additional .5-hr. may be claimed if cleaning is required.

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.