Rating:

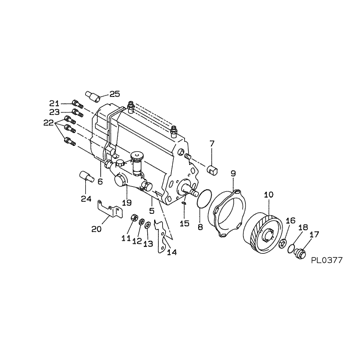

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

FH/FK/FM 6D14

Engine

6D14

Serial start-end

9404-

Info

Injector Nozzle

093500-2820

Injector nozzle:

0935002820

KIT List:

Part name

Kit1

Kit2

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09200-00750

PUMP ASSY, INJECTI

A6,R801

Include in ##:

09200-00750

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09200-00750

PUMP ASSY, INJECTI

Information:

Remove & Install Fuel Injection Lines

1. Thoroughly clean the area around each fuel injection line connection before removal of any fuel injection lines. 2. Remove bolts (3) and (5) that fasten the mounting brackets to the cylinder head.3. Disconnect all fuel injection line nuts (2) at the fuel injection pump housing.

Do not let the tops of fuel injection nozzles (4) turn when fuel injection line nuts (6) are tightened. The nozzles will be damaged if the top of the nozzle turns in the body. The engine will be damaged if a defective fuel injection nozzle is used because the shape of fuel (spray pattern) that comes out of the nozzles will not be correct.

4. Use two wrenches, one to hold fuel injection nozzles (4) so they will not turn and one to disconnect fuel injection lines (1) from the nozzles.5. Remove fuel injection lines (1) from the engine. Put caps and plugs on the nozzles, fuel injection lines and fuel injection pump housing to keep dirt from entering the fuel system. The following steps are for installation of the fuel injection lines.6. Make sure the fuel injection lines are clean and dry.7. Put fuel injection lines (1) in position. Install all fuel injection line nuts (2) and (6) until they are finger tighten.8. Use a torque wrench and Tool (A) to tighten all fuel injection line nuts (2) to a torque of 41 7 N m (30 5 lb ft).

Do not let the tops of fuel injection nozzles (4) turn when the fuel injection lines are tightened. The nozzles will be damaged if the top of the nozzle turns in the body. The engine will be damaged if a defective fuel injection nozzle is used because the shape of fuel (spray pattern) that comes out of the nozzles will not be correct.

9. Use a wrench to hold fuel injection nozzles (4) so they will not turn. Use a torque wrench and Tool (A) to tighten all fuel injection line nuts (6) to a torque of 41 7 N m (30 5 lb ft).10. Install bolts (3) and (5) that fasten the mounting brackets to the cylinder head.11. Remove (bleed) the air from the fuel system. See the Operation & Maintenance Manual.

1. Thoroughly clean the area around each fuel injection line connection before removal of any fuel injection lines. 2. Remove bolts (3) and (5) that fasten the mounting brackets to the cylinder head.3. Disconnect all fuel injection line nuts (2) at the fuel injection pump housing.

Do not let the tops of fuel injection nozzles (4) turn when fuel injection line nuts (6) are tightened. The nozzles will be damaged if the top of the nozzle turns in the body. The engine will be damaged if a defective fuel injection nozzle is used because the shape of fuel (spray pattern) that comes out of the nozzles will not be correct.

4. Use two wrenches, one to hold fuel injection nozzles (4) so they will not turn and one to disconnect fuel injection lines (1) from the nozzles.5. Remove fuel injection lines (1) from the engine. Put caps and plugs on the nozzles, fuel injection lines and fuel injection pump housing to keep dirt from entering the fuel system. The following steps are for installation of the fuel injection lines.6. Make sure the fuel injection lines are clean and dry.7. Put fuel injection lines (1) in position. Install all fuel injection line nuts (2) and (6) until they are finger tighten.8. Use a torque wrench and Tool (A) to tighten all fuel injection line nuts (2) to a torque of 41 7 N m (30 5 lb ft).

Do not let the tops of fuel injection nozzles (4) turn when the fuel injection lines are tightened. The nozzles will be damaged if the top of the nozzle turns in the body. The engine will be damaged if a defective fuel injection nozzle is used because the shape of fuel (spray pattern) that comes out of the nozzles will not be correct.

9. Use a wrench to hold fuel injection nozzles (4) so they will not turn. Use a torque wrench and Tool (A) to tighten all fuel injection line nuts (6) to a torque of 41 7 N m (30 5 lb ft).10. Install bolts (3) and (5) that fasten the mounting brackets to the cylinder head.11. Remove (bleed) the air from the fuel system. See the Operation & Maintenance Manual.