Rating:

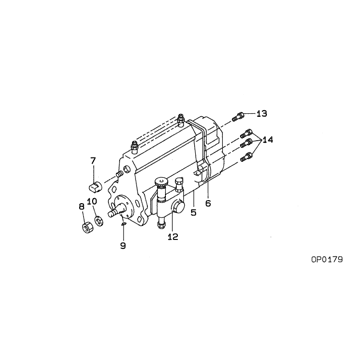

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL S6S

Engine

S6S

Serial start-end

9312-

Info

Injector Nozzle

093500-5870

Injector nozzle:

0935005870

KIT List:

Part name

Kit1

Kit2

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

09200-00660

PUMP ASSY, INJECTI

Information:

Start By:a. remove rocker arm assemblies and push rods 1. Remove injector hold down bolt (1).

Do not pry on the injector hold down bracket. Damage to the injector could occur. The injector has a notch in it on the side opposite the rack. This notch is used for prying the injector loose. Also, do not move the fuel injector rack without the injector spring slightly compressed. Damage to the injector could occur.

2. Use Tool (A) to loosen the fuel injector; then rotate the fuel injector to disengage the injector rack from the fuel control linkage. Remove the fuel injector. Be sure both O-ring seals (2) are on the fuel injector. The following steps are for the installation of the unit fuel injectors.3. Check the condition of O-ring seals (2). If the seals are damaged, use new parts for replacement. Install the O-ring seals on in the fuel injector.4. Lubricate the O-ring seals on the fuel injector with clean engine oil.5. Position the fuel injector in the cylinder head assembly; then rotate it to engage the injector rack with the fuel control linkage. Push down on the top of the fuel injector so the O-ring seals slide into the bore in the cylinder head assembly. Be sure the fuel injector is seated properly before installing bolt (1) that holds it in position. Do not use bolt (1) to pull the fuel injector down into the cylinder head assembly.6. Install bolt (1), and tighten it.7. After installation of the rocker arm assemblies and push rods, Check and/or adjust the following: Injector Synchronization, Fuel Setting, Fuel Timing, Valve Lash. See the 3114 & 3116 Diesel Truck Engines Systems Operation Testing & Adjusting module, Form No. SENR6437 to check and/or adjust the above items.End By:a. install rocker arm assemblies and push rods

Do not pry on the injector hold down bracket. Damage to the injector could occur. The injector has a notch in it on the side opposite the rack. This notch is used for prying the injector loose. Also, do not move the fuel injector rack without the injector spring slightly compressed. Damage to the injector could occur.

2. Use Tool (A) to loosen the fuel injector; then rotate the fuel injector to disengage the injector rack from the fuel control linkage. Remove the fuel injector. Be sure both O-ring seals (2) are on the fuel injector. The following steps are for the installation of the unit fuel injectors.3. Check the condition of O-ring seals (2). If the seals are damaged, use new parts for replacement. Install the O-ring seals on in the fuel injector.4. Lubricate the O-ring seals on the fuel injector with clean engine oil.5. Position the fuel injector in the cylinder head assembly; then rotate it to engage the injector rack with the fuel control linkage. Push down on the top of the fuel injector so the O-ring seals slide into the bore in the cylinder head assembly. Be sure the fuel injector is seated properly before installing bolt (1) that holds it in position. Do not use bolt (1) to pull the fuel injector down into the cylinder head assembly.6. Install bolt (1), and tighten it.7. After installation of the rocker arm assemblies and push rods, Check and/or adjust the following: Injector Synchronization, Fuel Setting, Fuel Timing, Valve Lash. See the 3114 & 3116 Diesel Truck Engines Systems Operation Testing & Adjusting module, Form No. SENR6437 to check and/or adjust the above items.End By:a. install rocker arm assemblies and push rods