Rating:

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL F4L912

Engine

F4L912

Serial start-end

7603--8412

Info

Injector Nozzle

KIT List:

Part name

Kit1

Kit2

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09000-09840

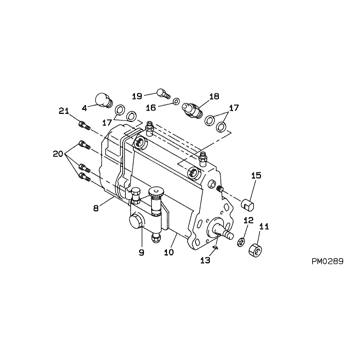

PUMP ASSY, INJECTI

A4,RSV

Include in ##:

09000-09840

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09000-09840

PUMP ASSY, INJECTI

Information:

DO NOT adjust the linkage so the treadle can be used to shut off the engine. If the operator is in a standing position and places a foot on the treadle, the engine could be unexpectedly shut off, creating a situation where the machine can be difficult to control.

518 Skidder

1. Move governor shaft (3) to SHUT OFF position and install lever (2) on shaft (3) at angle (A).2. Adjust length of rod (5) so stop (4) on pedal (1) is at dimension (B) from the floor plate.Angle (A) ... 35 5°Dimension (B) ... 67 1 mm (2.64 .01 in)3. Tighten nut (6) ... 12 4 N m (9 3 lb ft)D5H

1. Move governor lever (2) to high idle and install spring (6). Move governor lever (2) to vertical position and adjust stop bolt (3) to contact lever (2), back off one turn and lock.2. Position lever (9) on the splined governor shaft to 35 5° from vertical in shut off position.3. Adjust rod end (10) to obtain a free fit of bolt (8) and lever (7).4. Position lever (2) in low idle position. Use a spring scale to monitor the force needed to pull the governor lever (2), just below knob (1), from low idle to high idle position. Repeat and adjust housing (5) to obtain a force of 40 5 N (9 1 lb).5. With engine running, move governor lever (2) to high idle. At correct high idle RPM adjust high idle stop bolt (4) to contact lever (2), back off one turn and lock.6. Tighten rod end lock nuts to 14 4 N m (10 3 lb ft).

Decelerator Adjustment

(1) Decelerator pedal. (2) Decelerator rpm bolt.1. Adjust and lock decelerator rpm bolt (2) so that engine speed is: D5H (7NC, 1YD, 9HC, 2SD) ... 850 50 rpmD5H (8RC, 3MD, 1DD, 4KD) ... 1300 50 rpm with decelerator pedal (1) fully depressed.2. Recheck high idle rpm.215, 215B, 215C, 219, 225, 225B, 229

1. With control lever (3) positioned against economy idle stop, adjust cable (4) to operate engine at: 215, 215B, 215C, 219 ... 1750 50 rpm225, 225B, 229 ... 1850 50 rpm2. Tighten nuts (1) to ... 5.0 5 N m (4 .37 lb ft)3. Tighten nuts (2) to ... 100 15 N m (75 11 lb ft)936, 936E, 950B, 950E

1. Set governor shaft to the off position. Attach lever (1) approximately 35° forward from vertical.2. Assemble cable assembly (3) and rod end (2) to the governor housing.3. Adjust cable assembly (3) until hole in rod end (2) is 7 mm (.28 in) to 10 mm (.39 in) forward of the hole in the lever (1). Tighten nuts (4) to 8 5 N m (6 4 lb ft).4. Pull cable assembly (3) out to align holes and attach rod end (2) to lever (1).5. Attach governor pedal (7) to shaft.6. Set governor lever to high idle and adjust