Rating:

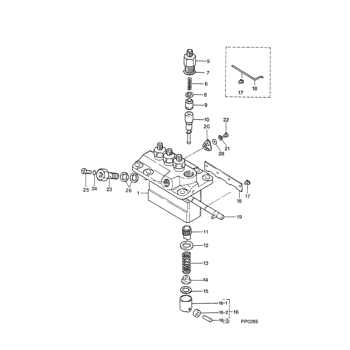

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

TRACTOR V1500

Engine

V1500

Serial start-end

8007--8201

Info

Injector Nozzle

093500-1230

Injector nozzle:

0935001230

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09000-08380

PUMP ASSY, INJECTI

PFR4M

Include in ##:

09000-08380

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09000-08380

PUMP ASSY, INJECTI

Information:

3306B Model Views: Air Cleaner (1), Turbocharger (2), Exhaust (3), Service (Hour) Meter (4), Crankcase Breather (5), Instrument Panel (6), Lifting Eye (7), Oil Filler (8), Fuel Pressure Gauge (9), Fuel Filter (10), Fuel Priming Pump (11), Fumes Disposal Tube (12), Magnetic Pickup Location (13), Crankshaft Vibration Damper (14), Flywheel Housing (15), Oil Drain (16), Oil Level Gauge (17), and Oil Filter (18).

Standby Generator Set: Control and Power Panel (1), Optional Battery Charger Mounting Location (2), Air Cleaner (3), Solenoid (4), Fuel Priming Pump (5), Exhaust (6), Governor Control Lever (7), Crankcase Breather (8), Radiator Fill Cap (9), Circuit Breaker (10), Optional Radiator Vent Hose (11), Lifting Location (12), Starting Motor (13), Oil Drain (14), Fuel Filter (15), and Water Drain (16).

Building Service Standby (BSSB) Generator Set: Control and Power Panel (1), Optional Total Enclosure (2), Air Cleaner (3), Fuel Priming Pump (4), Governor Control Lever (5), Crankcase Breather (6), Radiator Fill Cap (7), Lifting Location (8), Starting Motor (9), Fuel Filter (10), and Oil Drain (11).

Prime Generator Set: Control and Power Panel (1), Air Inlet (2), Solenoid (3), Turbocharger (4), Exhaust (5), Governor Control Lever (6), Crankcase Breather (7), Fuel Pressure Gauge (8), Radiator Fill Cap (9), Lifting Location (10), Starting Motor (11), Fuel Priming Pump (12), Fuel Filter (13), Oil Drain (14), and Water Drain (15).Engine Information

The engines are available with direct fuel injection. The engines can be naturally aspirated, turbocharged, or turbocharged with jacket water aftercooling. The 3306B is also available turbocharged with air-to-air aftercooling (ATAAC).A full-range hydramechanical governor controls the fuel injection pump output, maintaining the engine rpm selected by the operator. Individual injection pumps (one for each cylinder) meter and pump fuel under high pressure to injection nozzles. Automatic timing advance provides the best fuel injection timing over the full range of engine speed.The cooling system consists of: * a gear driven centrifugal pump (with one thermostat which regulates the engine coolant temperature)* an oil cooler, and* a radiator (incorporating a shunt system).The engine lubricating oil, which is both cooled and filtered, is supplied by a gear-type pump. Bypass valves provide unrestricted flow of lubrication oil to the engine parts if oil viscosity is high, or if the oil cooler or the oil filter elements become plugged.Engine efficiency, efficiency of emission controls, and engine performance depend on adherence to proper operation and maintenance recommendations. Engine performance and efficiency also depend on the use of recommended fuels and lubrication oils. Follow the recommended Maintenance Schedule found in this publication, paying attention to emission related components, air cleaner, oil, oil filter, fuel and fuel filter maintenance.