Rating:

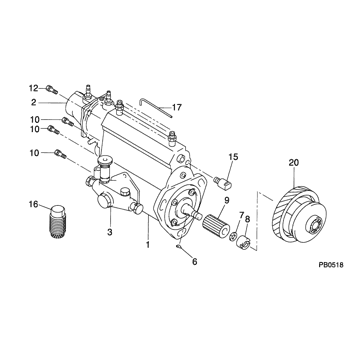

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL H

Engine

H

Serial start-end

7201--7204

Info

Injector Nozzle

093500-0910

Injector nozzle:

0935000910

KIT List:

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

09000-03410

PUMP ASSY, INJECTI

0900003410

25800-30200-71

TOYOTA

PUMP ASSY, INJECTI

Information:

Fuel Injection Nozzles

Test/Exchange

Fuel injection nozzles are subject of tip wear. Tip wear, a result of fuel contamination, can cause:* increased fuel consumption.* black smoke.* misfire.* rough running.Fuel nozzles should be cleaned, inspected, tested, and replaced if necessary. Refer to Special Instruction SEHS7292, for using the 8S2245 Nozzle Cleaning Kit. Consult with your Caterpillar dealer about fuel injection nozzle cleaning and testing.

Never wire brush or scrape a fuel injection nozzle. Wire brushing or scraping a fuel injection nozzle will damage the finely machined orifice. Proper tools for cleaning and testing fuel injection nozzles can be obtained from authorized Caterpillar dealers.

Abnormal engine running, smoke emission, and engine knock can be symptoms of nozzle malfunction. Each nozzle must be isolated one at a time in order to determine the malfunctioning nozzle.1. Start the engine.

A fuel injection nozzle will be damaged if the top of the nozzle turns in the body. The engine will be damaged if a defective fuel injection nozzle is used because the fuel spray pattern that comes out of the nozzle will be incorrect. Fuel injection nozzles can be permanently damaged by twisting if only one wrench is used to loosen or tighten the fuel line nuts. Do NOT let the tops of the fuel nozzles turn when the fuel lines are loosened. Use one wrench to hold the nozzle and another to loosen the fuel line nut.

2. Loosen each fuel line nut at the fuel injection pump, one at a time. A cloth or similar material must be used to prevent fuel from spraying on the hot exhaust components. Tighten each nut before loosening the next nut.3. A defective nozzle may be identified when a nut is loosened and:* the exhaust smoking is partially or completely eliminated.* irregular running is not affected.A nozzle suspected of being defective should be removed. A new nozzle should be installed in the cylinder to determine if the removed nozzle is defective.Removing and Installing Fuel Injection Nozzles

Special tooling is required to remove and install nozzles. Refer to the Service Manual for information. Consult with your Caterpillar dealer for assistance.Inspect, Rebuild or Exchange

If the engine is operated until the component(s) fails, additional engine damage can result. Caterpillar recommends that the following components be injected at the 5000 Hour maintenance interval.* Jacket Water Pump* Turbocharger* Alternator* Starting MotorCaterpillar Recommendation

To minimize downtime, Caterpillar recommends the use of Remanufactured components (subject to availability) as the most cost effective option.Removal and Installation

Refer to the Service Manual or contact your Caterpillar dealer for assistance with removal and installation of engine components.Jacket Water Pump

A failed water pump might cause severe engine overheating problems that could result in cracks in the cylinder head, a piston seizure or other potential damage to the engine.Visually inspect the water pump for leaks. If leaking is observed, replace all seals. Refer to the Service Manual for the procedure to replace the seals.Turbocharger

Refer to the Turbocharger topic in the Every 3000 Hours maintenance interval for information regarding turbocharger inspection. Refer to the Service Manual, or

Test/Exchange

Fuel injection nozzles are subject of tip wear. Tip wear, a result of fuel contamination, can cause:* increased fuel consumption.* black smoke.* misfire.* rough running.Fuel nozzles should be cleaned, inspected, tested, and replaced if necessary. Refer to Special Instruction SEHS7292, for using the 8S2245 Nozzle Cleaning Kit. Consult with your Caterpillar dealer about fuel injection nozzle cleaning and testing.

Never wire brush or scrape a fuel injection nozzle. Wire brushing or scraping a fuel injection nozzle will damage the finely machined orifice. Proper tools for cleaning and testing fuel injection nozzles can be obtained from authorized Caterpillar dealers.

Abnormal engine running, smoke emission, and engine knock can be symptoms of nozzle malfunction. Each nozzle must be isolated one at a time in order to determine the malfunctioning nozzle.1. Start the engine.

A fuel injection nozzle will be damaged if the top of the nozzle turns in the body. The engine will be damaged if a defective fuel injection nozzle is used because the fuel spray pattern that comes out of the nozzle will be incorrect. Fuel injection nozzles can be permanently damaged by twisting if only one wrench is used to loosen or tighten the fuel line nuts. Do NOT let the tops of the fuel nozzles turn when the fuel lines are loosened. Use one wrench to hold the nozzle and another to loosen the fuel line nut.

2. Loosen each fuel line nut at the fuel injection pump, one at a time. A cloth or similar material must be used to prevent fuel from spraying on the hot exhaust components. Tighten each nut before loosening the next nut.3. A defective nozzle may be identified when a nut is loosened and:* the exhaust smoking is partially or completely eliminated.* irregular running is not affected.A nozzle suspected of being defective should be removed. A new nozzle should be installed in the cylinder to determine if the removed nozzle is defective.Removing and Installing Fuel Injection Nozzles

Special tooling is required to remove and install nozzles. Refer to the Service Manual for information. Consult with your Caterpillar dealer for assistance.Inspect, Rebuild or Exchange

If the engine is operated until the component(s) fails, additional engine damage can result. Caterpillar recommends that the following components be injected at the 5000 Hour maintenance interval.* Jacket Water Pump* Turbocharger* Alternator* Starting MotorCaterpillar Recommendation

To minimize downtime, Caterpillar recommends the use of Remanufactured components (subject to availability) as the most cost effective option.Removal and Installation

Refer to the Service Manual or contact your Caterpillar dealer for assistance with removal and installation of engine components.Jacket Water Pump

A failed water pump might cause severe engine overheating problems that could result in cracks in the cylinder head, a piston seizure or other potential damage to the engine.Visually inspect the water pump for leaks. If leaking is observed, replace all seals. Refer to the Service Manual for the procedure to replace the seals.Turbocharger

Refer to the Turbocharger topic in the Every 3000 Hours maintenance interval for information regarding turbocharger inspection. Refer to the Service Manual, or