Rating:

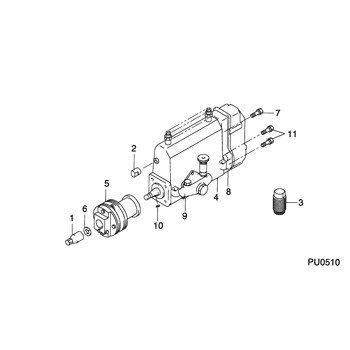

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL 4D120-11ASP

Engine

4D120-11ASP

Serial start-end

7706--8001

Info

Injector Nozzle

093500-0510

Injector nozzle:

0935000510

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

09000-02290

PUMP ASSY, INJECTI

Information:

Safety

The safety section lists basic safety precautions. In addition, this section identifies hazardous, warning situations. Read and understand the basic precautions listed in the safety section before operating or performing lubrication, maintenance and/or repair on this product.Operation

Engine operation outlined in this publication is basic. Engine operators gain knowledge of the engine through experience, developing operation skills and techniques which enhance efficient and economical engine operation.The operation section is a reference for operators. Photographs and illustrations guide operators through correct procedures of inspecting, starting, operating and stopping the engine. Discussion of gauges and engine control information is included.Maintenance

The maintenance section is a guide to engine care. The illustrated instructions are grouped by maintenance service intervals. The actual operating environment of the engine also governs the maintenance schedule. Under extremely severe, dusty, or frigid operating conditions, lubrication and maintenance checks more frequent than those specified in the Maintenance Schedule may be necessary. Maintenance Intervals

Use the service hour meter to determine service intervals. Calendar intervals shown (daily, weekly, monthly, etc.) can be used instead of service hour meter intervals, if they provide more convenient serving schedules and approximate the indicated service hour meter reading. Recommended service should always be performed at the interval that occurs first.We recommend that the maintenance schedules be reproduced for ease of inspection. We also recommend that ongoing maintenance records be kept to document engine service. See the Maintenance Records section of this publication for information regarding documents that are generally accepted as proof of maintenance or repair. Your Caterpillar dealer can assist you in tailoring your Maintenance Schedule to meet the needs of your operating environment.Overhaul

Major engine repair details are not covered in this manual. Major repairs are best left to trained personnel or an authorized Caterpillar dealer.If a major engine failure requiring removal of the engine occurs, numerous after-failure overhaul options available from your Caterpillar dealer. Contact your dealer for information regarding these options.Engine Storage

For general information, refer to the Engine Lifting & Storage topic. For complete engine storage information refer to Special Instruction SEHS9031, Storage Procedure for Caterpillar Products.California

Proposition 65 WarningDiesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm.

The safety section lists basic safety precautions. In addition, this section identifies hazardous, warning situations. Read and understand the basic precautions listed in the safety section before operating or performing lubrication, maintenance and/or repair on this product.Operation

Engine operation outlined in this publication is basic. Engine operators gain knowledge of the engine through experience, developing operation skills and techniques which enhance efficient and economical engine operation.The operation section is a reference for operators. Photographs and illustrations guide operators through correct procedures of inspecting, starting, operating and stopping the engine. Discussion of gauges and engine control information is included.Maintenance

The maintenance section is a guide to engine care. The illustrated instructions are grouped by maintenance service intervals. The actual operating environment of the engine also governs the maintenance schedule. Under extremely severe, dusty, or frigid operating conditions, lubrication and maintenance checks more frequent than those specified in the Maintenance Schedule may be necessary. Maintenance Intervals

Use the service hour meter to determine service intervals. Calendar intervals shown (daily, weekly, monthly, etc.) can be used instead of service hour meter intervals, if they provide more convenient serving schedules and approximate the indicated service hour meter reading. Recommended service should always be performed at the interval that occurs first.We recommend that the maintenance schedules be reproduced for ease of inspection. We also recommend that ongoing maintenance records be kept to document engine service. See the Maintenance Records section of this publication for information regarding documents that are generally accepted as proof of maintenance or repair. Your Caterpillar dealer can assist you in tailoring your Maintenance Schedule to meet the needs of your operating environment.Overhaul

Major engine repair details are not covered in this manual. Major repairs are best left to trained personnel or an authorized Caterpillar dealer.If a major engine failure requiring removal of the engine occurs, numerous after-failure overhaul options available from your Caterpillar dealer. Contact your dealer for information regarding these options.Engine Storage

For general information, refer to the Engine Lifting & Storage topic. For complete engine storage information refer to Special Instruction SEHS9031, Storage Procedure for Caterpillar Products.California

Proposition 65 WarningDiesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm.