Rating:

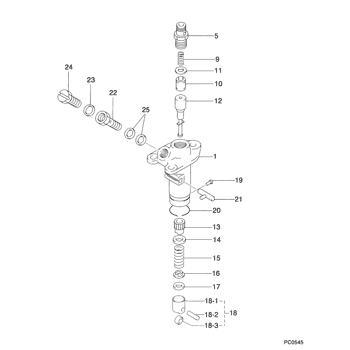

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL VC-2

Engine

VC-2

Serial start-end

7401--7412

Info

Injector Nozzle

093500-1230

Injector nozzle:

0935001230

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

09000-00810

PUMP ASSY, INJECTI

0900000810

14206-51012

KUBOTA

PUMP ASSY, INJECTI

Information:

Overhaul

Overhaul Considerations

Reduced hours of operation at full load and/or operating at reduced settings result in lower average power demand. Lower average power demand should increase the length of operating time before an engine overhaul is required.An overhaul is generally indicated by increased fuel consumption and reduced power. Overhaul includes completely reconditioning your cylinder head, but the cylinder components are not worn enough to need repair.Factors such as: conscientious preventive maintenance, fuel quality used, operating conditions, S*O*S oil analysis results, etc., are important considerations in deciding when to perform an overhaul.Estimating Oil Consumption

Oil consumption, fuel consumption, and maintenance information can be used to estimate the total operating cost for your Caterpillar engine. Oil consumption can also be used to estimate the capacity of a makeup oil system required to accommodate your maintenance intervals.Oil consumption is proportional to the engine operating percent load. The higher the percent load, the higher the amount of oil consumed per hour.The oil consumption rate, or brake specific oil consumption (BSOC) is measured in grams/brake kW-hour (lb/bhp-hour). The BSOC varies depending on the load on your engine. Contact your Caterpillar dealer for assistance in determining typical oil consumption for your engine.Oil Consumption as an Overhaul Indicator

When an engine's oil consumption has risen to three times the initial (new) consumption rate due to normal wear, then the engine should be scheduled for overhaul. There may be a corresponding increase in blowby and a slight increase in fuel consumption.Overhaul Before Failure

A planned Overhaul Before Failure may be your best value, because you can:* Avoid costly unplanned downtime.* Reuse as many original parts as standards permit.* Extend your engine's service life without the risk of a major catastrophe had you continued to operate to failure.* Get the best cost/value relationship per hour of extended life.After Failure Overhaul

If you experience a major engine failure which requires removal of the engine from the hull, there are also many After Failure Overhaul options available. An overhaul should be performed if your block or crankshaft needs to be repaired.If the block and/or crankshaft is repairable, overhaul cost should be between 40 and 50 percent of the cost of a new engine (with like exchange core).This lower cost can be attributed to Caterpillar "designed-in" features, Caterpillar dealer and Caterpillar Remanufactured exchange components.Overhaul Recommendation

To minimize downtime and provide you with the lowest cost and highest value, Caterpillar recommends that the engine be overhauled before failure by scheduling an overhaul with your Caterpillar dealer. Overhaul programs vary with engine application and from dealer to dealer. Therefore, Caterpillar recommends that you confer with your dealer to obtain specific information regarding the types of programs offered and overhaul services provided for extending the life of your engine.If you elect to perform an overhaul without Caterpillar dealer overhaul service, you should be aware of the maintenance that follows.Inspect/Rebuild or Exchange

Cylinder Head, Connecting Rods, Pistons, Cylinder Liners, Turbocharger, Oil Pump, Spacer Plates, Fuel Ratio Control, Cam Followers, Fuel Transfer Pump, and Timing Advance.

These components should be inspected according to

Overhaul Considerations

Reduced hours of operation at full load and/or operating at reduced settings result in lower average power demand. Lower average power demand should increase the length of operating time before an engine overhaul is required.An overhaul is generally indicated by increased fuel consumption and reduced power. Overhaul includes completely reconditioning your cylinder head, but the cylinder components are not worn enough to need repair.Factors such as: conscientious preventive maintenance, fuel quality used, operating conditions, S*O*S oil analysis results, etc., are important considerations in deciding when to perform an overhaul.Estimating Oil Consumption

Oil consumption, fuel consumption, and maintenance information can be used to estimate the total operating cost for your Caterpillar engine. Oil consumption can also be used to estimate the capacity of a makeup oil system required to accommodate your maintenance intervals.Oil consumption is proportional to the engine operating percent load. The higher the percent load, the higher the amount of oil consumed per hour.The oil consumption rate, or brake specific oil consumption (BSOC) is measured in grams/brake kW-hour (lb/bhp-hour). The BSOC varies depending on the load on your engine. Contact your Caterpillar dealer for assistance in determining typical oil consumption for your engine.Oil Consumption as an Overhaul Indicator

When an engine's oil consumption has risen to three times the initial (new) consumption rate due to normal wear, then the engine should be scheduled for overhaul. There may be a corresponding increase in blowby and a slight increase in fuel consumption.Overhaul Before Failure

A planned Overhaul Before Failure may be your best value, because you can:* Avoid costly unplanned downtime.* Reuse as many original parts as standards permit.* Extend your engine's service life without the risk of a major catastrophe had you continued to operate to failure.* Get the best cost/value relationship per hour of extended life.After Failure Overhaul

If you experience a major engine failure which requires removal of the engine from the hull, there are also many After Failure Overhaul options available. An overhaul should be performed if your block or crankshaft needs to be repaired.If the block and/or crankshaft is repairable, overhaul cost should be between 40 and 50 percent of the cost of a new engine (with like exchange core).This lower cost can be attributed to Caterpillar "designed-in" features, Caterpillar dealer and Caterpillar Remanufactured exchange components.Overhaul Recommendation

To minimize downtime and provide you with the lowest cost and highest value, Caterpillar recommends that the engine be overhauled before failure by scheduling an overhaul with your Caterpillar dealer. Overhaul programs vary with engine application and from dealer to dealer. Therefore, Caterpillar recommends that you confer with your dealer to obtain specific information regarding the types of programs offered and overhaul services provided for extending the life of your engine.If you elect to perform an overhaul without Caterpillar dealer overhaul service, you should be aware of the maintenance that follows.Inspect/Rebuild or Exchange

Cylinder Head, Connecting Rods, Pistons, Cylinder Liners, Turbocharger, Oil Pump, Spacer Plates, Fuel Ratio Control, Cam Followers, Fuel Transfer Pump, and Timing Advance.

These components should be inspected according to