Rating:

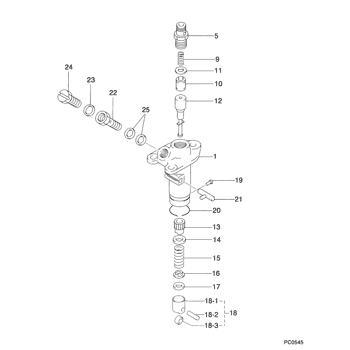

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL KND3

Engine

KND3

Serial start-end

7401--7412

Info

Injector Nozzle

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

09000-00580

PUMP ASSY, INJECTI

0900000580

15021-51013

KUBOTA

PUMP ASSY, INJECTI

Information:

Water

Distilled or deionized water is recommended for use in cooling systems. DO NOT use hard, tap water or salt softened tap water in engine cooling systems. If Distilled or deionized water is NOT available, use water that meets the Minimum Acceptable requirements listed in the following chart.

ppm=parts per million

Water that does not meet the Minimum Acceptable limits will reduce engine service life when used in cooling systems.

If you are not sure of your water's contents, contact your Caterpillar dealer, your local water department, agricultural agent, or an independent laboratory to analyze the water.Additives

Additives must be included in all coolant mixtures. Additives help prevent the formation of rust, scale and mineral deposits. Additives protect metals from corrosion, prevent liner cavitation, and contain anti-foaming agents. Additives deplete during engine operation and need to be replenished. This is done through the addition of supplemental coolant additives (SCAs, with conventional coolants) or Extender (with Caterpillar Long Life Coolant/Antifreeze).Nitrites or nitrite and molybdate additives protect the cylinder liner from cavitation corrosion. Nitrites deplete, creating the need for SCAs or Extender. SCAs and Extender also contain other inhibitors that deplete from cooling systems.Under-concentration of additives does not provide the protection required for cooling systems. Over-concentration can cause additives to drop out of solution, deposit inside the cooling system, or form a gel in the radiator. Deposits can be in the form of sludge and scale which accumulate on hot engine surfaces, reducing cooling system effectiveness, or causing water pump leaks.To maintain conventional cooling system protection, it is necessary to monitor SCA concentration. Incorrect SCA concentration requires action to return proper additive levels to the cooling system.Glycol

Engine coolant glycol is normally one of two varieties, ethylene or propylene. Glycol raises the boiling point of water to help prevent boil-over, provides freeze protection, helps prevent water pump cavitation, and reduces cylinder liner pitting.

For ambient temperatures requiring lower freeze protection (higher than 50 percent glycol), use ethylene glycol. DO NOT use propylene glycol.

Proper anti-freeze/boil protection requires the proper rate of glycol and Acceptable water. Use the following charts to determine glycol concentrations to mix with Acceptable water. Check the coolant solution periodically to ensure adequate anti-freeze/boil protection. Use the 1U7298 (°C) or the 1U7297 (°F) Refractometer. These Refractometers give immediate, accurate readings and can be used with ethylene or propylene glycol. For more detailed specifications, refer to: Know Your Cooling System, SEBD0518, and Coolant and Your Engine, SEBD0970, or contact your Caterpillar dealer.Caterpillar Coolant Recommendations

* Preferred- Caterpillar Long Life Coolant/Antifreeze (LLCA).Conventional Antifreeze/Coolant

* Recommended- Caterpillar Diesel Engine Antifreeze/Coolant (DEAC).* Acceptable- Any low silicate coolant that meets Truck Maintenance Council (TMC) Recommended Practice (RP) 329, TMC RP330, or ASTM D4985 requirements when used with SCAs.* Permitted-A mixture of Acceptable Water and SCA, where freeze protection is not necessary.* Unacceptable- ANY high silicate coolant that is classified as meeting ASTM D3306.

Most commercial engine coolant/antifreezes are formulated for gasoline engine applications and have high silicate content. High silicates provide conditions favoring cylinder liner cavitation and corrosion. Caterpillar DOES NOT recommend these

Distilled or deionized water is recommended for use in cooling systems. DO NOT use hard, tap water or salt softened tap water in engine cooling systems. If Distilled or deionized water is NOT available, use water that meets the Minimum Acceptable requirements listed in the following chart.

ppm=parts per million

Water that does not meet the Minimum Acceptable limits will reduce engine service life when used in cooling systems.

If you are not sure of your water's contents, contact your Caterpillar dealer, your local water department, agricultural agent, or an independent laboratory to analyze the water.Additives

Additives must be included in all coolant mixtures. Additives help prevent the formation of rust, scale and mineral deposits. Additives protect metals from corrosion, prevent liner cavitation, and contain anti-foaming agents. Additives deplete during engine operation and need to be replenished. This is done through the addition of supplemental coolant additives (SCAs, with conventional coolants) or Extender (with Caterpillar Long Life Coolant/Antifreeze).Nitrites or nitrite and molybdate additives protect the cylinder liner from cavitation corrosion. Nitrites deplete, creating the need for SCAs or Extender. SCAs and Extender also contain other inhibitors that deplete from cooling systems.Under-concentration of additives does not provide the protection required for cooling systems. Over-concentration can cause additives to drop out of solution, deposit inside the cooling system, or form a gel in the radiator. Deposits can be in the form of sludge and scale which accumulate on hot engine surfaces, reducing cooling system effectiveness, or causing water pump leaks.To maintain conventional cooling system protection, it is necessary to monitor SCA concentration. Incorrect SCA concentration requires action to return proper additive levels to the cooling system.Glycol

Engine coolant glycol is normally one of two varieties, ethylene or propylene. Glycol raises the boiling point of water to help prevent boil-over, provides freeze protection, helps prevent water pump cavitation, and reduces cylinder liner pitting.

For ambient temperatures requiring lower freeze protection (higher than 50 percent glycol), use ethylene glycol. DO NOT use propylene glycol.

Proper anti-freeze/boil protection requires the proper rate of glycol and Acceptable water. Use the following charts to determine glycol concentrations to mix with Acceptable water. Check the coolant solution periodically to ensure adequate anti-freeze/boil protection. Use the 1U7298 (°C) or the 1U7297 (°F) Refractometer. These Refractometers give immediate, accurate readings and can be used with ethylene or propylene glycol. For more detailed specifications, refer to: Know Your Cooling System, SEBD0518, and Coolant and Your Engine, SEBD0970, or contact your Caterpillar dealer.Caterpillar Coolant Recommendations

* Preferred- Caterpillar Long Life Coolant/Antifreeze (LLCA).Conventional Antifreeze/Coolant

* Recommended- Caterpillar Diesel Engine Antifreeze/Coolant (DEAC).* Acceptable- Any low silicate coolant that meets Truck Maintenance Council (TMC) Recommended Practice (RP) 329, TMC RP330, or ASTM D4985 requirements when used with SCAs.* Permitted-A mixture of Acceptable Water and SCA, where freeze protection is not necessary.* Unacceptable- ANY high silicate coolant that is classified as meeting ASTM D3306.

Most commercial engine coolant/antifreezes are formulated for gasoline engine applications and have high silicate content. High silicates provide conditions favoring cylinder liner cavitation and corrosion. Caterpillar DOES NOT recommend these