Rating:

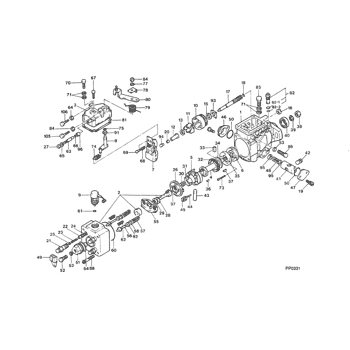

Information plug, governor sle Denso

Include in ##:

09600-00431

as PLUG, GOVERNOR SLE

Cross reference number

Part num

Firm num

Firm

Name

09625-60680

22787-1714

PLUG, GOVERNOR SLE

0962560680

22787-17142

TOYOTA

PLUG, GOVERNOR SLE

0962560680

8-97161935-0

ISUZU

PLUG, GOVERNOR SLE

Information:

Engine

Steam Clean

Accumulated grease and oil on an engine is a fire hazard. Remove this debris each time a significant quantity of oil is spilled on the engine.

Steam cleaning your engine is a good preventive maintenance practice because it provides you with a way to detect oil and coolant leaks. Repairing an oil or coolant leak upon detection may save you money by avoiding major repairs that could result from low oil or coolant levels.Steam cleaning the engine as recommended will also improve the engine's heat transfer characteristics.Turbocharger

Inspect/Check

1. Remove the exhaust outlet piping and inlet piping from the turbocharger.2. Turn the turbine and compressor wheel by hand.3. The assembly should turn freely.4. Inspect the turbine wheel and compressor wheel for contact with the turbocharger housing.5. There should NOT be any visible signs of contact between the turbine wheel or compressor wheel and the turbocharger housing. When installing or replacing V-band clamp, position the gap (tightening screw) down if possible so any water will drain away.6. Visually check for oil leaks.

Turbocharger bearing failures can cause large quantities of oil to enter the air intake and exhaust systems. Loss of engine lubricant can result in serious engine damage. Minor leakage of a turbocharger housing under extended low idle operation will not cause problems as long as no turbocharger bearing failure occurred.When a turbocharger bearing failure is accompanied by a significant engine performance loss (exhaust smoke or engine speed up at no load), DO NOT continue engine operation until the turbocharger is repaired or replaced.

If maintenance is required, refer to PM Level 3 in this publication for turbocharger service options.Engine Mounts

Inspect/Check

Front engine mount shown.Caterpillar recommends checking the engine mounts for deterioration and proper bolt torque. This will prevent excessive engine vibration caused from improper mounting. See your Service Manual or OEM truck manufacturer for recommended torque values.Vibration Damper

Inspect/Check

Damage to, or failure of, the damper will increase torsional vibrations and result in damage to the crankshaft and other engine components. A failing vibration damper will cause more gear train noise at variable points in the speed range. The vibration damper has marks on the hub (1) and ring (2). These marks will indicate the condition of the vibration damper. If the marks are not in alignment, the rubber seal (3) between the ring and the hub has separated from the ring and/or hub. If the marks are not in alignment, install a new vibration damper.A used vibration damper can have a visual wobble (movement to the front and rear when in rotation) on the outer ring. This does not mean a replacement is necessary since some wobble of the outer ring is normal. To see if the amount of wobble is acceptable, or replacement is necessary, check the damper with the procedure in the Testing and Adjusting section of the Service Manual.Air Compressor

Inspect/Check

Do not disconnect the air line from the air compressor governor without purging the air brake and auxiliary air systems. Failure to purge the air brake and auxiliary air systems before

Steam Clean

Accumulated grease and oil on an engine is a fire hazard. Remove this debris each time a significant quantity of oil is spilled on the engine.

Steam cleaning your engine is a good preventive maintenance practice because it provides you with a way to detect oil and coolant leaks. Repairing an oil or coolant leak upon detection may save you money by avoiding major repairs that could result from low oil or coolant levels.Steam cleaning the engine as recommended will also improve the engine's heat transfer characteristics.Turbocharger

Inspect/Check

1. Remove the exhaust outlet piping and inlet piping from the turbocharger.2. Turn the turbine and compressor wheel by hand.3. The assembly should turn freely.4. Inspect the turbine wheel and compressor wheel for contact with the turbocharger housing.5. There should NOT be any visible signs of contact between the turbine wheel or compressor wheel and the turbocharger housing. When installing or replacing V-band clamp, position the gap (tightening screw) down if possible so any water will drain away.6. Visually check for oil leaks.

Turbocharger bearing failures can cause large quantities of oil to enter the air intake and exhaust systems. Loss of engine lubricant can result in serious engine damage. Minor leakage of a turbocharger housing under extended low idle operation will not cause problems as long as no turbocharger bearing failure occurred.When a turbocharger bearing failure is accompanied by a significant engine performance loss (exhaust smoke or engine speed up at no load), DO NOT continue engine operation until the turbocharger is repaired or replaced.

If maintenance is required, refer to PM Level 3 in this publication for turbocharger service options.Engine Mounts

Inspect/Check

Front engine mount shown.Caterpillar recommends checking the engine mounts for deterioration and proper bolt torque. This will prevent excessive engine vibration caused from improper mounting. See your Service Manual or OEM truck manufacturer for recommended torque values.Vibration Damper

Inspect/Check

Damage to, or failure of, the damper will increase torsional vibrations and result in damage to the crankshaft and other engine components. A failing vibration damper will cause more gear train noise at variable points in the speed range. The vibration damper has marks on the hub (1) and ring (2). These marks will indicate the condition of the vibration damper. If the marks are not in alignment, the rubber seal (3) between the ring and the hub has separated from the ring and/or hub. If the marks are not in alignment, install a new vibration damper.A used vibration damper can have a visual wobble (movement to the front and rear when in rotation) on the outer ring. This does not mean a replacement is necessary since some wobble of the outer ring is normal. To see if the amount of wobble is acceptable, or replacement is necessary, check the damper with the procedure in the Testing and Adjusting section of the Service Manual.Air Compressor

Inspect/Check

Do not disconnect the air line from the air compressor governor without purging the air brake and auxiliary air systems. Failure to purge the air brake and auxiliary air systems before