Rating:

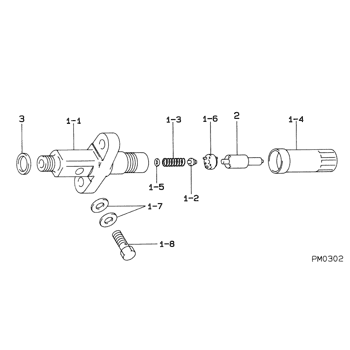

Information pin, nozzle holder Denso

Include in ##:

09350-02940

as PIN, NOZZLE HOLDER

Cross reference number

Part num

Firm num

Firm

Name

09312-10460

PIN, NOZZLE HOLDER

Information:

Main Control Panel

The main control panel may or may not contain all of the components shown. Some components are optional, and may not be required for your particular application.

Optional panel lights (1), optional governor switch (shown) or speed potentiometer (2), optional starting aid switch (3), engine control switch (4), optional alarm module (shown) or synchronizing lights module (5), voltage adjust rheostat (6), emergency stop push button (7), generator set control (8), and optional panel light switch (9).* The panel lights (PL) (1) are controlled by the panel light switch (PLS) (9).* The voltage adjust rheostat (VAR) (6), is used to adjust the generator output voltage.* The optional governor switch (GS) or speed potentiometer (SP) (2) is used to raise or lower the engine speed. If the governor is equipped with a speed adjust motor, the governor switch is mounted in this location. If the engine is equipped with an electric governor, a speed potentiometer is mounted in this location.* The starting aid switch (SAS) (3) is used to inject ether into the engine for starting in cold weather conditions. When the starting aid switch is moved to the ON position, the switch energizes and meters a specific amount of ether in a holding chamber. When the switch is released, the solenoid releases the ether to the engine.* The emergency stop push button (ESPB) (7) is used to shut down the engine during an emergency situation. The ESPB shuts off the fuel and activates the optional air shutoff (if equipped).* The engine control switch (ECS) (4), determines the status of the control panel. In the Automatic position (3 o'clock), the engine will start automatically whenever the remote initiating contact is closed. The engine will shutdown after the initiating contact opens and adjustable cool down time has elapsed. The cool down time can be programmed to give a 0 to 30 minute cool down period before the engine shuts down.When the ECS is in the Manual Run position (6 o'clock), the engine will start and run as long as the ECS remains in this position.When the ECS is in the Stop position (9 o'clock), the fuel solenoid shuts the engine down, after a programmable cool down time period.When the ECS is in the Off/Reset position (12 o'clock), the fault lights are reset and the engine shuts down immediately.Generator Set Control (GSC)

The left side of the control panel contains the Generator Set Control (GSC). This is the "main" component of the system, and also displays generator output, generator set functions, fault conditions, and key engine parameters.The GSC accepts information from the operator, magnetic pickup, oil pressure and water temperature sensors, and optional remote sources. The accept information is used to determine the "on/off" state of the engine's air, fuel, and starter.In the very basic operating conditions, the GSC

The main control panel may or may not contain all of the components shown. Some components are optional, and may not be required for your particular application.

Optional panel lights (1), optional governor switch (shown) or speed potentiometer (2), optional starting aid switch (3), engine control switch (4), optional alarm module (shown) or synchronizing lights module (5), voltage adjust rheostat (6), emergency stop push button (7), generator set control (8), and optional panel light switch (9).* The panel lights (PL) (1) are controlled by the panel light switch (PLS) (9).* The voltage adjust rheostat (VAR) (6), is used to adjust the generator output voltage.* The optional governor switch (GS) or speed potentiometer (SP) (2) is used to raise or lower the engine speed. If the governor is equipped with a speed adjust motor, the governor switch is mounted in this location. If the engine is equipped with an electric governor, a speed potentiometer is mounted in this location.* The starting aid switch (SAS) (3) is used to inject ether into the engine for starting in cold weather conditions. When the starting aid switch is moved to the ON position, the switch energizes and meters a specific amount of ether in a holding chamber. When the switch is released, the solenoid releases the ether to the engine.* The emergency stop push button (ESPB) (7) is used to shut down the engine during an emergency situation. The ESPB shuts off the fuel and activates the optional air shutoff (if equipped).* The engine control switch (ECS) (4), determines the status of the control panel. In the Automatic position (3 o'clock), the engine will start automatically whenever the remote initiating contact is closed. The engine will shutdown after the initiating contact opens and adjustable cool down time has elapsed. The cool down time can be programmed to give a 0 to 30 minute cool down period before the engine shuts down.When the ECS is in the Manual Run position (6 o'clock), the engine will start and run as long as the ECS remains in this position.When the ECS is in the Stop position (9 o'clock), the fuel solenoid shuts the engine down, after a programmable cool down time period.When the ECS is in the Off/Reset position (12 o'clock), the fault lights are reset and the engine shuts down immediately.Generator Set Control (GSC)

The left side of the control panel contains the Generator Set Control (GSC). This is the "main" component of the system, and also displays generator output, generator set functions, fault conditions, and key engine parameters.The GSC accepts information from the operator, magnetic pickup, oil pressure and water temperature sensors, and optional remote sources. The accept information is used to determine the "on/off" state of the engine's air, fuel, and starter.In the very basic operating conditions, the GSC