Rating:

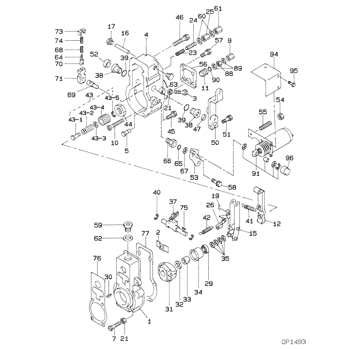

Information over-haul kit, gov Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Hacus - Forklift FPE297321 STOP SOLENOID 24V. S6S Hacus Aftermarket - New

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Hacus - Forklift FPE349109 Stop Solenoid 24V. S6S Hacus Aftermarket - New

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Include in ##:

19080-01250

as OVER-HAUL KIT, GOV

Cross reference number

Part num

Firm num

Firm

Name

19089-00600

OVER-HAUL KIT, GOV

Information:

1. Disconnect hose assemblies (4) and (5) from elbow (6).2. Loosen the clamps that hold hose (1) in place. and move hose (1) away from elbow (6).3. Remove the bolt, lock and elbow (6) from the turbocharger.4. Loosen the clamps that hold elbow (7) in place, and move the elbow away from the turbocharger.5. Remove tube assemblies (8) and (9).6. Remove the clamp that holds pipe assembly (2) in position, and move the pipe assembly away from the turbocharger.7. Fasten a hoist to turbocharger (3). Remove the nuts that hold the turbocharger to the exhaust manifold, and remove the turbocharger. The weight of the turbocharger is 23 kg (51 lb.). The following steps are for installation of the turbocharger.8. Install the gasket between the turbocharger (3) and the exhaust manifold. Put 5P3931 Anti-Seize Compound on the threads of the bolts, and install the bolts and nuts that hold the turbocharger to the exhaust manifold. Tighten the bolts to a torque of 55 5 N m (41 4 lb.ft.).9. Make sure the gaskets are in position on tube assemblies (8) and (9), and install the tube assemblies.10. Put pipe assembly (2) in position on the turbocharger, and install the clamp that holds it.11. Put elbow (7) in position on the turbocharger, and install the clamps that hold it in place.12. Put elbow (6) in position in the turbocharger and hose (1). Tighten the clamps that hold the hose to the elbow.13. Install the lock and bolt to hold elbow (6) in position in the turbocharger.14. Connect hose assemblies (4) and (5) to elbow (6).Disassemble Turbocharger

1. Install the turbocharger on tool (A) as shown.2. Put alignment marks on three housings of the turbocharger for correct alignment during assembly. Loosen clamp (2), and remove the clamp and housing (1) from housing assembly (3). 3. Loosen clamp (4), and remove housing assembly (3) from housing (5). 4. Put the cartridge group in position in tool (B) as shown.

When the nut is loosened, do not put a side force on the shaft. This can result in a bent shaft.

5. Use a 5S9566 Sliding T-Wrench and a universal socket (6) to remove the nut that holds the compressor wheel to the wheel assembly.6. Remove compressor wheel (7) and the shims from wheel assembly (8).7. Remove housing assembly (3) from wheel assembly (8). 8. Remove ring (9) and backplate (10) from wheel assembly (8). 9. Use tool (C), and remove snap ring (11) from housing assembly (3). 10. Remove insert (12) and sleeve (13) from housing assembly (3). 11. Remove ring (14) from sleeve (13). 12. Remove two screws (15) and deflector (16) from housing assembly (3). 13. Remove ring (18) and bearing assembly (17) from the housing assembly. 14. Remove sleeve (19) and ring (20) from the housing assembly. 15. Remove O-ring seal (23) from the housing assembly.16. Use tool (D), and remove snap ring (22) from the housing assembly.17. Remove bearing (21). Remove the snap ring behind the bearing with tool

1. Install the turbocharger on tool (A) as shown.2. Put alignment marks on three housings of the turbocharger for correct alignment during assembly. Loosen clamp (2), and remove the clamp and housing (1) from housing assembly (3). 3. Loosen clamp (4), and remove housing assembly (3) from housing (5). 4. Put the cartridge group in position in tool (B) as shown.

When the nut is loosened, do not put a side force on the shaft. This can result in a bent shaft.

5. Use a 5S9566 Sliding T-Wrench and a universal socket (6) to remove the nut that holds the compressor wheel to the wheel assembly.6. Remove compressor wheel (7) and the shims from wheel assembly (8).7. Remove housing assembly (3) from wheel assembly (8). 8. Remove ring (9) and backplate (10) from wheel assembly (8). 9. Use tool (C), and remove snap ring (11) from housing assembly (3). 10. Remove insert (12) and sleeve (13) from housing assembly (3). 11. Remove ring (14) from sleeve (13). 12. Remove two screws (15) and deflector (16) from housing assembly (3). 13. Remove ring (18) and bearing assembly (17) from the housing assembly. 14. Remove sleeve (19) and ring (20) from the housing assembly. 15. Remove O-ring seal (23) from the housing assembly.16. Use tool (D), and remove snap ring (22) from the housing assembly.17. Remove bearing (21). Remove the snap ring behind the bearing with tool