Rating:

Information o-ring Denso

Include in ##:

09010-01680

as O-RING

Cross reference number

Part num

Firm num

Firm

Name

94914-01550

22817-1110

O-RING

9491401550

22817-1110A

HINO

O-RING

Information:

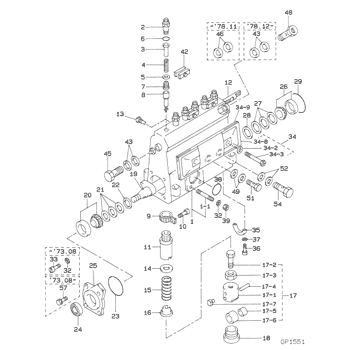

Start By:a. remove fuel injection lines1. Drain the cooling system below level of the aftercooler. 2. Remove two bolts (2) that hold water line elbow (1) to aftercooler. Remove water line (3) from front elbow. 3. Disconnect fuel and air lines (4) from the fuel injection pump housing. Put caps on fuel line openings. 4. Remove bolts (6) and (7) that hold bracket (5) to fuel injection pump housing and cylinder head. Remove bracket (5). Remove bolts (8) on each side of the pump. 5. Remove bolts and cover (11). Retainer (10) is free to fall into the housing when bolts (9) are removed.6. Remove the cover and remove bolts (9) that hold the automatic timing advance to the end of the fuel pump camshaft. 7. Fasten Tooling (A) and a hoist to the fuel injection pump housing and governor. Remove fuel injection pump housing and governor (11). Weight of the unit is 66 kg (145 lb).Install Fuel Injection Pump Housing & Governor

1. Remove the plug from the front of the injection pump housing. Install Tool (B) (as shown) through the hole in the pump housing and into the timing notch in the fuel injection pump camshaft. 2. Put a small amount of 5P-0960 Multipurpose Type Grease on O-ring seal (2).3. Fasten Tooling (A) and a hoist to fuel injection pump and governor (1). Put the fuel injection pump housing into position on top of the engine. 4. Put retainer (4) and bolts (3) in position on the automatic timing advance. Tighten the bolts evenly to a torque of 70 N m (50 lb ft). Remove Tool (B) and tighten the bolts evenly to a torque of 135 7 N m (100 5 lb ft).5. Use Tool (C) to turn the engine in a counterclockwise direction (as seen from the flywheel end of the engine) until the No. 1 piston is at top center on compression stroke. Install timing bolt (1) in the flywheel. See the topic "Finding Top Center Compression Position For No. 1 Piston" in Systems Operating Testing & Adjusting.6. If timing is correct, Tool (B) will go into the notch in the fuel injection pump camshaft and the timing bolt will turn freely into the threaded hole in the flywheel, if timing is not correct, remove Tool (B) and the timing bolt and do the following procedure:a. Make sure Tool (B) is removed from the fuel injection pump camshaft. Loosen four bolts which hold the automatic timing advance unit on the fuel pump camshaft.b. Tighten the bolts with fingers until there is a small amount of friction (slight drag) between the retainer and the timing advance unit. This will prevent movement (backlash) when the gears are turned to the correct timing.c. Use Tool (C) to turn the engine in a counterclockwise direction (as seen from

1. Remove the plug from the front of the injection pump housing. Install Tool (B) (as shown) through the hole in the pump housing and into the timing notch in the fuel injection pump camshaft. 2. Put a small amount of 5P-0960 Multipurpose Type Grease on O-ring seal (2).3. Fasten Tooling (A) and a hoist to fuel injection pump and governor (1). Put the fuel injection pump housing into position on top of the engine. 4. Put retainer (4) and bolts (3) in position on the automatic timing advance. Tighten the bolts evenly to a torque of 70 N m (50 lb ft). Remove Tool (B) and tighten the bolts evenly to a torque of 135 7 N m (100 5 lb ft).5. Use Tool (C) to turn the engine in a counterclockwise direction (as seen from the flywheel end of the engine) until the No. 1 piston is at top center on compression stroke. Install timing bolt (1) in the flywheel. See the topic "Finding Top Center Compression Position For No. 1 Piston" in Systems Operating Testing & Adjusting.6. If timing is correct, Tool (B) will go into the notch in the fuel injection pump camshaft and the timing bolt will turn freely into the threaded hole in the flywheel, if timing is not correct, remove Tool (B) and the timing bolt and do the following procedure:a. Make sure Tool (B) is removed from the fuel injection pump camshaft. Loosen four bolts which hold the automatic timing advance unit on the fuel pump camshaft.b. Tighten the bolts with fingers until there is a small amount of friction (slight drag) between the retainer and the timing advance unit. This will prevent movement (backlash) when the gears are turned to the correct timing.c. Use Tool (C) to turn the engine in a counterclockwise direction (as seen from