Rating:

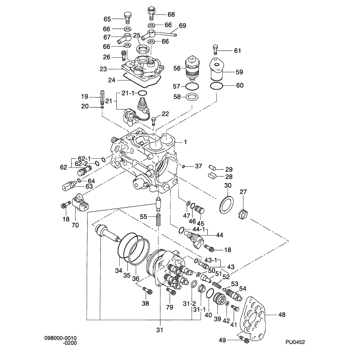

Information o-ring, distributi Denso

Include in ##:

09800-00010

as O-RING, DISTRIBUTI

Cross reference number

Part num

Firm num

Firm

Name

09806-60040

O-RING, DISTRIBUTI

Information:

2. Remove the liners from the block with tooling (A).

Be careful not to cause damage to the block or the piston cooling tubes when the cylinder liner is removed with tooling (A).

3. Remove the O-rings from the bottom of the liner. Remove the filler band at the top of the liner.Install Cylinder Liners

1. Thoroughly clean the spacer plate and surface of the cylinder block.2. Install a new spacer plate gasket. Install the spacer plate. Install two bolts on both sides of the liner to be checked. The surfaces of the spacer plate and cylinder block must be clean and dry.4. Tighten the bolts evenly as follows: 10 lb.ft. (13.6 N m), 25 lb.ft. (33.9 N m), 50 lb.ft. (67.8 N m) and to a final torque of 70 lb.ft. (94.9 N m). 5. Install the cylinder liner in the block without O-ring or filler band. Install tooling (A) and (B) as shown. To prevent movement of bolts and washers as each cylinder liner is checked, install two bolts and washers (2) on each side of each liner to be checked. 6. The bolts (1) that hold the crossbar (4) of tool (B) must be tightened evenly in four steps as follows: 5 lb.ft. (6.8 N m), 15 lb.ft. (20.3 N m), 25 lb.ft. (33.9 N m) and 50 lb.ft. (67.8 N m) torque. The distance from the bottom of crossbar (4) to the top of the spacer plate (5) must be the same on both sides of the cylinder liner.7. Put the dial indicator (3) on zero. Measure the liner height as close as possible to the bolts at four locations around the cylinder liner. The height must be .0020 to .0076 in. (0.05 to 0.19 mm) and four measurements must be within .002 in. (0.05 mm) of each other. The average height between cylinders must not have a difference of more than .002 in. (0.05 mm). 8. The thickness of the spacer plate (5) is .5142 .001 in. (13.061 0.03 mm). The thickness of a new gasket under the spacer plate is .008 .001 in. (0.20 0.03 mm). The thickness of a new liner flange (6) is .5260 .008 in. (13.360 0.020 mm). If the cylinder liner is turned, it can make a difference in liner height. If the height is correct, put a mark on the liner and the spacer plate so the liner can be installed in the correct position. If the cylinder liner height is not correct, make an adjustment to the block. See Form FM055228 for correct procedure.9. Remove tooling (A) and (B). Remove the cylinder liner from the block. Install new O-ring seals on the bottom of the liner. Put liquid soap on the O-ring seals and in the block.

TYPICAL EXAMPLE10. Put clean diesel fuel on the filler band (7) and immediately install it on the liner. Put clean engine oil on the outside of the filler band and immediately install the liner in the block

Be careful not to cause damage to the block or the piston cooling tubes when the cylinder liner is removed with tooling (A).

3. Remove the O-rings from the bottom of the liner. Remove the filler band at the top of the liner.Install Cylinder Liners

1. Thoroughly clean the spacer plate and surface of the cylinder block.2. Install a new spacer plate gasket. Install the spacer plate. Install two bolts on both sides of the liner to be checked. The surfaces of the spacer plate and cylinder block must be clean and dry.4. Tighten the bolts evenly as follows: 10 lb.ft. (13.6 N m), 25 lb.ft. (33.9 N m), 50 lb.ft. (67.8 N m) and to a final torque of 70 lb.ft. (94.9 N m). 5. Install the cylinder liner in the block without O-ring or filler band. Install tooling (A) and (B) as shown. To prevent movement of bolts and washers as each cylinder liner is checked, install two bolts and washers (2) on each side of each liner to be checked. 6. The bolts (1) that hold the crossbar (4) of tool (B) must be tightened evenly in four steps as follows: 5 lb.ft. (6.8 N m), 15 lb.ft. (20.3 N m), 25 lb.ft. (33.9 N m) and 50 lb.ft. (67.8 N m) torque. The distance from the bottom of crossbar (4) to the top of the spacer plate (5) must be the same on both sides of the cylinder liner.7. Put the dial indicator (3) on zero. Measure the liner height as close as possible to the bolts at four locations around the cylinder liner. The height must be .0020 to .0076 in. (0.05 to 0.19 mm) and four measurements must be within .002 in. (0.05 mm) of each other. The average height between cylinders must not have a difference of more than .002 in. (0.05 mm). 8. The thickness of the spacer plate (5) is .5142 .001 in. (13.061 0.03 mm). The thickness of a new gasket under the spacer plate is .008 .001 in. (0.20 0.03 mm). The thickness of a new liner flange (6) is .5260 .008 in. (13.360 0.020 mm). If the cylinder liner is turned, it can make a difference in liner height. If the height is correct, put a mark on the liner and the spacer plate so the liner can be installed in the correct position. If the cylinder liner height is not correct, make an adjustment to the block. See Form FM055228 for correct procedure.9. Remove tooling (A) and (B). Remove the cylinder liner from the block. Install new O-ring seals on the bottom of the liner. Put liquid soap on the O-ring seals and in the block.

TYPICAL EXAMPLE10. Put clean diesel fuel on the filler band (7) and immediately install it on the liner. Put clean engine oil on the outside of the filler band and immediately install the liner in the block