Rating:

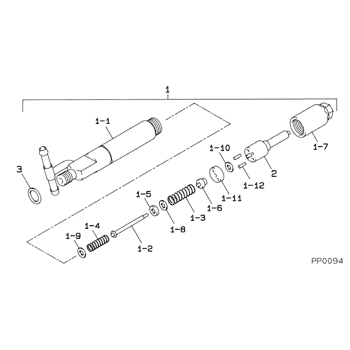

Information nozzle assy Denso

Nozzle Type:

ND-DLLA146P667

MITSUBISHI CANTER 4D34T4

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

4PCS Diesel Fuel Injector Atomizer Mist Projector Thrower Fuel Coating Gun Spray Nozzle for 4D34T4 DLLA146P667 093400-6670

Generic

Generic

Nozzle DLLA146P667 093400-6670 Fuel Injector Nozzle for 4D34T4

Generic

Generic

$67.99

23 May 2023

0.88[0.40] Pounds

CN: lutong part plant

6Pcs Fuel Injector Nozzles DLLA146P667 093400-6670 Fits for Mitsubishi Canter 4D34

DICSCL PARCS Diesel Injector Nozzle DLLA146P667 093400-6670 fits for Mitsubishi Fuso Canter 4D34 6pcs/lot || Material: Made of high quality for longer durability and strength.100% quality inspection to ensure the high quality. Upgraded packaging to avoid damage. || Easy Installation:No further modification to direct replacement. || OEM Part Number:DLLA146P667,093400-6670 || Estimated Time of Delivery from China: 5-10 working days.Customer satisfaction is always our top priority, we are standing by ready to provide you with reliable assistance with any questions you may have

DICSCL PARCS Diesel Injector Nozzle DLLA146P667 093400-6670 fits for Mitsubishi Fuso Canter 4D34 6pcs/lot || Material: Made of high quality for longer durability and strength.100% quality inspection to ensure the high quality. Upgraded packaging to avoid damage. || Easy Installation:No further modification to direct replacement. || OEM Part Number:DLLA146P667,093400-6670 || Estimated Time of Delivery from China: 5-10 working days.Customer satisfaction is always our top priority, we are standing by ready to provide you with reliable assistance with any questions you may have

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09340-06670

NOZZLE ASSY

Information:

Table 1

Revision Table

Revision Summary of Changes

3 Added serial numbers. Improvement Procedure

Clean oil rail after pump failure.Reference: Refer to Special Instruction, REHS3819 for the procedure to clean the oil rail after engine failure to avoid debris in the oil system.

Use clean oil and clean filters.The life of the injector depends on the oil quality. It can be increased if good cleaning practices are performed before installing the injectors.Reference: Refer to Operation and Maintenance Manual, SEBU6250 and Operation and Maintenance Manual, SEBU6251 for direction on oil sampling intervals and optimizing engine oil life.

Illustration 1 g06207717

(1) Actuator

(2) Pump Group

(3) Valve Seat Damage Due to Debris in the Oil SystemInjector Failure Due To Damage From Debris In The Oil May Not Be A Warrantable Failure

Illustration 2 g06244961