Rating:

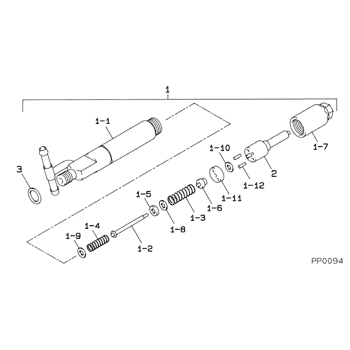

Information nozzle assy Denso

Nozzle Type:

ND-DLLA154P642

MITSUBISHI CANTER 4D33-4

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

4PCS Fuel Injector Atomizer Mist Projector Thrower Atomization Coating Gun Sprayer Nozzle 093400-6420 DLLA154P642 for 4D33

Generic

Generic

CNDIP P Type Diesel Injector Nozzle 093400-6420 Fuel Tip DLLA154P642 With

Generic

Generic

DAINUN [Replacement] 4PCS 093400-6420 DLLA154P642 for Diesel Fuel Injector Nozzle Replacement Parts Accessories for Mitsubishi for Fuso for Canter 4D33 4D35

DAINUN 【Product Quality】The product is perfect as described, providing you with the best performance and reliability. || 【Excellent Performance】Made according to the original factory specifications, very simple to install and very easy to use. || 【Professional Factory】We have a professional factory with sufficient stock. || 【Warm Reminder】Please check the product related information carefully to make sure it is what you need. || 【Quality Service】We have a professional after-sales team to provide you with quality service, you can rest assured that the purchase.

DAINUN 【Product Quality】The product is perfect as described, providing you with the best performance and reliability. || 【Excellent Performance】Made according to the original factory specifications, very simple to install and very easy to use. || 【Professional Factory】We have a professional factory with sufficient stock. || 【Warm Reminder】Please check the product related information carefully to make sure it is what you need. || 【Quality Service】We have a professional after-sales team to provide you with quality service, you can rest assured that the purchase.

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09340-06420

ME736511

NOZZLE ASSY

0934006420

ME736511

MITSUBISHI

NOZZLE ASSY

Information:

Non-Unidirectional Requirements

(r) Directional Requirements for Diesel Emission Control Strategies

Every diesel emission control strategy must be installed as designed and specified by the manufacturer. For a diesel emission control strategy comprised of multiple exhaust aftertreatment parts, each aftertreatment part must be installed in the proper order relative to the exhaust flow.

Diesel emission control strategies installed between February 19, 2009, and January 1, 2010.

(A) The diesel emission control strategy must indicate the proper direction of exhaust flow. This exhaust flow indicator will allow the end user or installer to see how to install the device properly.

Diesel emission control strategies installed on or after January 1, 2010.

(A) The proper direction for exhaust to flow through the aftertreatment part of the diesel emission control strategy is to be clearly indicated on the outside surface of the aftertreatment part. The exhaust flow indicator consists of an arrow imprinted on or affixed to the aftertreatment part. The indicator arrow is to be clearly visible and durable.

(B) The aftertreatment part must be constructed such that the part can only be installed into the diesel emission control strategy in one unique direction relative to the exhaust flow. The aftertreatment part cannot be installed in the reversed direction.

(C) A diesel emission control strategy not meeting these requirements may be installed after January 1, 2010, if the diesel emission controls strategy: (1) Has a date of manufacture no later than December 31, 2009, (2) Complies with (r)(1) and (r)(2) above and (3) Is installed no later than December 31 2011.

(D) Except for an aftertreatment part that reduces PM through a physical trapping mechanism, such as a diesel particulate filter, the applicant may request that the Executive Officer waives the requirements that an aftertreatment part indicates the flow direction and have unidirectional construction. In reviewing the request, the Executive Officer may consider all relevant information including, but not limited to, the symmetry of the aftertreatment part, potential for impaired performance as a result of different orientations relative to exhaust flow, and interaction with other parts.Diesel Particulate Filter Operation

The Cat DPF is a catalyzed diesel particulate filter that is designed to reduce emissions of particulate (smoke), carbon monoxide (CO) and hydrocarbons (HC), from diesel engines. Carbon monoxide and hydrocarbon reductions are achieved when the exhaust gases interact with the catalyst on the ceramic filter. The catalyst is impregnated on the walls of the ceramic substrate. As the exhaust gases come in contact with the catalyst, a chemical reaction takes place that oxidizes the gases. The oxidation process turns carbon monoxide into carbon dioxide, and hydrocarbons into water and carbon dioxide.Reduction of Emissions

The Cat DPF is a complete product for reducing carbon monoxide, hydrocarbons, and PM. The filter is catalyzed with a precious-metal catalyst. For CO and HC, the catalyst reduces the activation temperature needed in order to react with both types of compounds with oxygen (O2). Refer to illustration 1 below.

Illustration 1 g03825000

(1) Cell plugs (2) Exhaust out (3) Trapped soot (4) Carbon dioxide (5) Exhaust in (Soot, Carbon monoxide,

(r) Directional Requirements for Diesel Emission Control Strategies

Every diesel emission control strategy must be installed as designed and specified by the manufacturer. For a diesel emission control strategy comprised of multiple exhaust aftertreatment parts, each aftertreatment part must be installed in the proper order relative to the exhaust flow.

Diesel emission control strategies installed between February 19, 2009, and January 1, 2010.

(A) The diesel emission control strategy must indicate the proper direction of exhaust flow. This exhaust flow indicator will allow the end user or installer to see how to install the device properly.

Diesel emission control strategies installed on or after January 1, 2010.

(A) The proper direction for exhaust to flow through the aftertreatment part of the diesel emission control strategy is to be clearly indicated on the outside surface of the aftertreatment part. The exhaust flow indicator consists of an arrow imprinted on or affixed to the aftertreatment part. The indicator arrow is to be clearly visible and durable.

(B) The aftertreatment part must be constructed such that the part can only be installed into the diesel emission control strategy in one unique direction relative to the exhaust flow. The aftertreatment part cannot be installed in the reversed direction.

(C) A diesel emission control strategy not meeting these requirements may be installed after January 1, 2010, if the diesel emission controls strategy: (1) Has a date of manufacture no later than December 31, 2009, (2) Complies with (r)(1) and (r)(2) above and (3) Is installed no later than December 31 2011.

(D) Except for an aftertreatment part that reduces PM through a physical trapping mechanism, such as a diesel particulate filter, the applicant may request that the Executive Officer waives the requirements that an aftertreatment part indicates the flow direction and have unidirectional construction. In reviewing the request, the Executive Officer may consider all relevant information including, but not limited to, the symmetry of the aftertreatment part, potential for impaired performance as a result of different orientations relative to exhaust flow, and interaction with other parts.Diesel Particulate Filter Operation

The Cat DPF is a catalyzed diesel particulate filter that is designed to reduce emissions of particulate (smoke), carbon monoxide (CO) and hydrocarbons (HC), from diesel engines. Carbon monoxide and hydrocarbon reductions are achieved when the exhaust gases interact with the catalyst on the ceramic filter. The catalyst is impregnated on the walls of the ceramic substrate. As the exhaust gases come in contact with the catalyst, a chemical reaction takes place that oxidizes the gases. The oxidation process turns carbon monoxide into carbon dioxide, and hydrocarbons into water and carbon dioxide.Reduction of Emissions

The Cat DPF is a complete product for reducing carbon monoxide, hydrocarbons, and PM. The filter is catalyzed with a precious-metal catalyst. For CO and HC, the catalyst reduces the activation temperature needed in order to react with both types of compounds with oxygen (O2). Refer to illustration 1 below.

Illustration 1 g03825000

(1) Cell plugs (2) Exhaust out (3) Trapped soot (4) Carbon dioxide (5) Exhaust in (Soot, Carbon monoxide,

![DAINUN [Replacement] 4PCS 093400-6420 DLLA154P642 for Diesel Fuel Injector Nozzle Replacement Parts Accessories for Mitsubishi for Fuso for Canter 4D33 4D35](http://c1.a2109.com/_150/aws_api/31y/31yaf/31yafpv64jl.jpg)