Rating:

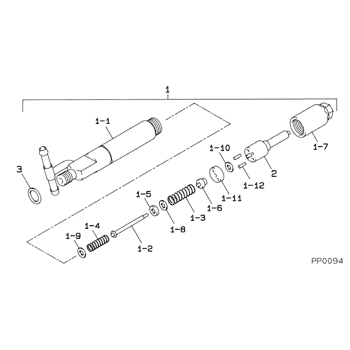

Information nozzle assy Denso

Nozzle Type:

ND-DLLA157P641

MITSUBISHI CANTER 4D33

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$17.45

25 Oct 2024

KR: Adabus

DEISEL Pump Assembly Injection Diesel Nozzle 093400-6410 / DLLA157P641 Spray Diesel Nozzle

Generic

Generic

$69.99

09 Mar 2024

0.88[0.40] Pounds

CN: lutong part plant

Fuel Injector Nozzle Tips DLLA157P641 093400-6410 Fits for Mitsubishi 4D35 6pcs/lot

DICSCL PARCS

DICSCL PARCS

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09340-06410

ME736510

NOZZLE ASSY

0934006410

ME736510

MITSUBISHI

NOZZLE ASSY

Information:

Introduction

Table 1

Revision History

Revision Summary of Changes

04 Added machine effectivity.

03 Made some changes in maintenance procedure section.

02 Table 2 information was updated.

01 Table 2 information was updated. This Special Instruction details the Diesel Particulate Filter (DPF) maintenance on C2.4, C3.3B, and C3.8 machine engines.Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.Reference

Reference: Special Instructions , REHS7788, "Cleaning the Diesel Particulate Filter (DPF) on C2.4, C3.3B, and C3.8 Engines."Reference: Troubleshooting , "Diesel Particulate Filter Active Regeneration Occurrence is Excessive".Reference: Troubleshooting , "Oil Contains Fuel".Reference: Disassembly and Assembly , "Diesel Particulate Filter- Remove and Install".Safety

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Failure to follow all safety guidelines prescribed in this document and by governing authorities and regulatory agencies may result in severe injury or death of personnel or machine damage.

When removing a major component or attachment, ensure that it is properly blocked or secured before removing mounting hardware. An assembly that is disconnected without proper blocking may shift or fall, resulting in serious injury or death of personnel or machine damage.

Personal injury or death can result from improper maintenance procedures. To avoid injury or death, follow the procedures exactly as stated below.

Personal injury can result from improper handling of chemicals.Make sure you use all the necessary protective equipment required to do the job.Make sure that you read and understand all directions and hazards described on the labels and material safety data sheet of any chemical that is used.Observe all safety precautions recommended by the chemical manufacturer for handling, storage, and disposal of chemicals.

Maintenance Procedure

There are three options for servicing the Diesel Particulate Filter (DPF).

Diesel Particulate Filter (DPF) can be cleaned by the Cat® dealer.

Replaced with a certified clean Diesel Particulate Filter (DPF) from Cat® Reman.

New Diesel Particulate Filter (DPF) installed.Note: The lowest cost option is the Diesel Particulate Filter (DPF) is cleaned by the Cat® dealer.

Refer to Special Instructions , REHS7788 for cleaning procedures.This document has the acceptable reuse guidelines such as max number of cracked or missing end caps and minimum remaining ash pin depth as measured by a pin gauge.Note: The C3.8 tier 4 final (EU stage 3B) currently does not have a certified clean Diesel Particulate Filter (DPF) available from Cat® Reman.

DPF cleaning is recommended to do at 3000 hrs as part of preventive maintenance, which ensures planned downtime. If the dealer and customer choose to not do this pro-actively at 3000 hrs, then Caterpillar is not responsible for any subsequent damage to the engine or emission components as a result.

If preventive maintenance is not done pro-actively, one of the following will occur which may indicate the Diesel Particulate Filter (DPF) is full or near full:

523602-0 High Frequency Regeneration code occurs.

Fuel Dilution is flagged in the

Table 1

Revision History

Revision Summary of Changes

04 Added machine effectivity.

03 Made some changes in maintenance procedure section.

02 Table 2 information was updated.

01 Table 2 information was updated. This Special Instruction details the Diesel Particulate Filter (DPF) maintenance on C2.4, C3.3B, and C3.8 machine engines.Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.Reference

Reference: Special Instructions , REHS7788, "Cleaning the Diesel Particulate Filter (DPF) on C2.4, C3.3B, and C3.8 Engines."Reference: Troubleshooting , "Diesel Particulate Filter Active Regeneration Occurrence is Excessive".Reference: Troubleshooting , "Oil Contains Fuel".Reference: Disassembly and Assembly , "Diesel Particulate Filter- Remove and Install".Safety

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Failure to follow all safety guidelines prescribed in this document and by governing authorities and regulatory agencies may result in severe injury or death of personnel or machine damage.

When removing a major component or attachment, ensure that it is properly blocked or secured before removing mounting hardware. An assembly that is disconnected without proper blocking may shift or fall, resulting in serious injury or death of personnel or machine damage.

Personal injury or death can result from improper maintenance procedures. To avoid injury or death, follow the procedures exactly as stated below.

Personal injury can result from improper handling of chemicals.Make sure you use all the necessary protective equipment required to do the job.Make sure that you read and understand all directions and hazards described on the labels and material safety data sheet of any chemical that is used.Observe all safety precautions recommended by the chemical manufacturer for handling, storage, and disposal of chemicals.

Maintenance Procedure

There are three options for servicing the Diesel Particulate Filter (DPF).

Diesel Particulate Filter (DPF) can be cleaned by the Cat® dealer.

Replaced with a certified clean Diesel Particulate Filter (DPF) from Cat® Reman.

New Diesel Particulate Filter (DPF) installed.Note: The lowest cost option is the Diesel Particulate Filter (DPF) is cleaned by the Cat® dealer.

Refer to Special Instructions , REHS7788 for cleaning procedures.This document has the acceptable reuse guidelines such as max number of cracked or missing end caps and minimum remaining ash pin depth as measured by a pin gauge.Note: The C3.8 tier 4 final (EU stage 3B) currently does not have a certified clean Diesel Particulate Filter (DPF) available from Cat® Reman.

DPF cleaning is recommended to do at 3000 hrs as part of preventive maintenance, which ensures planned downtime. If the dealer and customer choose to not do this pro-actively at 3000 hrs, then Caterpillar is not responsible for any subsequent damage to the engine or emission components as a result.

If preventive maintenance is not done pro-actively, one of the following will occur which may indicate the Diesel Particulate Filter (DPF) is full or near full:

523602-0 High Frequency Regeneration code occurs.

Fuel Dilution is flagged in the