Rating:

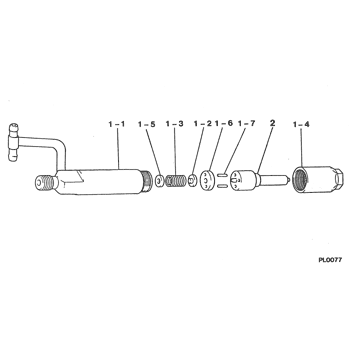

Information nozzle assy Denso

Nozzle Type:

ND-DLLA152P69

KOMATSU INDUSTRIAL SA6D108

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$69.99

23 Feb 2023

0.88[0.40] Pounds

CN: lutong part plant

Fuel Injector Nozzle Tips 093400-5690 DLLA152P69 Fits for KOMATSU 6D108 SA6D108 6pcs/lot

DICSCL PARCS Fuel Injector Nozzle Tips 093400-5690 DLLA152P69 fits for KOMATSU 6D108 SA6D108 6pcs/lot || Material: Made of high quality for longer durability and strength.100% quality inspection to ensure the high quality. Upgraded packaging to avoid damage. || Easy Installation:No further modification to direct replacement. || OEM Part Number:DLLA152P69 || Estimated Time of Delivery from China: 5-10 working days.Customer satisfaction is always our top priority, we are standing by ready to provide you with reliable assistance with any questions you may have

DICSCL PARCS Fuel Injector Nozzle Tips 093400-5690 DLLA152P69 fits for KOMATSU 6D108 SA6D108 6pcs/lot || Material: Made of high quality for longer durability and strength.100% quality inspection to ensure the high quality. Upgraded packaging to avoid damage. || Easy Installation:No further modification to direct replacement. || OEM Part Number:DLLA152P69 || Estimated Time of Delivery from China: 5-10 working days.Customer satisfaction is always our top priority, we are standing by ready to provide you with reliable assistance with any questions you may have

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09340-05690

NOZZLE ASSY

Information:

(5) Height of camshaft lobes.To find lobe height, use the procedure that follows:A. Measure camshaft lobe height (5).B. Measure base circle (7).C. Subtract base circle (STEP B) from lobe height (STEP A). The difference is actual lobe lift (6).D. Specified camshaft lobe lift (6) is: Camshaft Assemblya. Exhaust lobe ... 10.5 mm (.413 in)b. Inlet lobe ... 10.5 mm (.413 in)Maximum permissible difference between actual lobe lift (STEP C) and specified lobe lift (STEP D) is 0.13 mm (.005 in)Inlet Valve Timing

1. Check the No. 1 inlet valve lash with the engine stopped. The valve lash must be 0.30 to 0.46 mm (.012 to .018 in). If the valve lash is not in this range, adjust the lash to 0.38 mm (.015 in).2. Mark Top Center Position of the crankshaft on the vibration damper or pulley.3. Use a dial indicator to measure the inlet valve movement.4. Rotate the crankshaft in the direction of normal engine rotation. Stop when the inlet valve is 1.91 mm (.075 in) off its seat in the opening sequence.At this point the crankshaft Top Center Position Mark must be ... 5 2 degrees After Top CenterChecking Valve-Camshaft Timing (field procedure)

The following procedure will simplify the checking of the camshaft timing procedures.1. Set the No. 3 inlet bridge adjustment. Refer to SENR6547 (Testing And Adjusting).2. Set the No. 3 inlet valve lash. Refer to SENR6547 (Testing And Adjusting).3. Install the bolt in the flywheel with No. 1 piston at top center.4. Install the dial indicator (magnetic base) to No. 3 inlet bridge.5. Remove the bolt from the flywheel.6. Set the indicator at zero and rotate the engine in the normal direction of operation (counterclockwise as viewed from the flywheel end) until dial travel stops.The correct setting should be ... 14.21 0.25 mm (.560 .010 in)

1. Check the No. 1 inlet valve lash with the engine stopped. The valve lash must be 0.30 to 0.46 mm (.012 to .018 in). If the valve lash is not in this range, adjust the lash to 0.38 mm (.015 in).2. Mark Top Center Position of the crankshaft on the vibration damper or pulley.3. Use a dial indicator to measure the inlet valve movement.4. Rotate the crankshaft in the direction of normal engine rotation. Stop when the inlet valve is 1.91 mm (.075 in) off its seat in the opening sequence.At this point the crankshaft Top Center Position Mark must be ... 5 2 degrees After Top CenterChecking Valve-Camshaft Timing (field procedure)

The following procedure will simplify the checking of the camshaft timing procedures.1. Set the No. 3 inlet bridge adjustment. Refer to SENR6547 (Testing And Adjusting).2. Set the No. 3 inlet valve lash. Refer to SENR6547 (Testing And Adjusting).3. Install the bolt in the flywheel with No. 1 piston at top center.4. Install the dial indicator (magnetic base) to No. 3 inlet bridge.5. Remove the bolt from the flywheel.6. Set the indicator at zero and rotate the engine in the normal direction of operation (counterclockwise as viewed from the flywheel end) until dial travel stops.The correct setting should be ... 14.21 0.25 mm (.560 .010 in)