Rating:

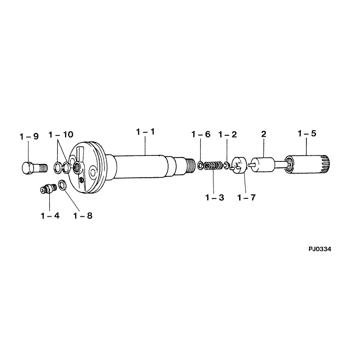

Information nozzle assy Denso

Nozzle Type:

ND-DLLA155SND160

KOMATSU Construction machine SA6D125

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

6PCS Diesel Fuel Injector Tips DLLA155SND160 Injectors Nozzle 0934001600 Compatible with KOMATSU 6D125 S6D125 PC300-5 MITSUBISHI 4M40/4M40T1 9432612954

DICSCL PARCS Part number: 093400-1600 , Stamping No: DLLA155SND160 || Compatible with KOMATSU 6D125 S6D125 PC300-5 MITSUBISHI 4M40/4M40T1 9432612954 || 100% brand new and high quality Made High-quality steel materia. || Longer Service Life: High quality durability material and excellent crafts, as well as the applied series of tests in RD center before they were listed, provide a reliable operation and longer service life of this item. || 【Notice】: Please check your car information before purchase.

DICSCL PARCS Part number: 093400-1600 , Stamping No: DLLA155SND160 || Compatible with KOMATSU 6D125 S6D125 PC300-5 MITSUBISHI 4M40/4M40T1 9432612954 || 100% brand new and high quality Made High-quality steel materia. || Longer Service Life: High quality durability material and excellent crafts, as well as the applied series of tests in RD center before they were listed, provide a reliable operation and longer service life of this item. || 【Notice】: Please check your car information before purchase.

4PCS Diesel Fuel Injector Tips DLLA155SND160 Injectors Nozzles 0934001600 Compatible with KOMATSU 6D125 S6D125 PC300-5 MITSUBISHI 4M40/4M40T1 9432612954

DICSCL PARCS Part number: 093400-1600 , Stamping No: DLLA155SND160 || Compatible with KOMATSU 6D125 S6D125 PC300-5 MITSUBISHI 4M40/4M40T1 9432612954 || 100% brand new and high quality Made High-quality steel materia. || Longer Service Life: High quality durability material and excellent crafts, as well as the applied series of tests in RD center before they were listed, provide a reliable operation and longer service life of this item. || 【Notice】: Please check your car information before purchase.

DICSCL PARCS Part number: 093400-1600 , Stamping No: DLLA155SND160 || Compatible with KOMATSU 6D125 S6D125 PC300-5 MITSUBISHI 4M40/4M40T1 9432612954 || 100% brand new and high quality Made High-quality steel materia. || Longer Service Life: High quality durability material and excellent crafts, as well as the applied series of tests in RD center before they were listed, provide a reliable operation and longer service life of this item. || 【Notice】: Please check your car information before purchase.

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09340-01600

NOZZLE ASSY

Information:

If water is not visible, or if water flow is restricted, stop the engine. The engine will overheat. Inspect the inlet screen and the sea water strainer for debris. Remove any debris if present.

Check the gauges and equipment for proper operation. Always increase engine speed before applying the load. Begin operating the engine at low load. The engine will reach normal operating temperature faster when operated at low speed and low power demand than when idled at no load. Typically, the engine should reach operating temperature in a few minutes. After normal oil pressure is reached and the temperature gauges begin to move, the engine may be operated at partial and then full load.If the load varies, or is cyclic, the governor will adjust the engine speed as required.Extended operation at low idle or reduced load may cause increased oil consumption and carbon build-up in the cylinders. This carbon build-up results in loss of power and/or poor performance. When operating at reduced load, the engine should be fully loaded to burn excess carbon from the cylinders at least every four hours. Check the gauges and equipment frequently while operating under load.Gauges readings should be observed and the data recorded frequently while the engine is operating. Comparing the data over time will help determine normal readings for each gauge, and help detect abnormal operating developments. Significant changes in the readings should be investigated.Engine and Marine Transmission Operation

Shifting the Marine Transmission

Full power is transferred from the engine, through the marine transmission, to the propeller shaft. The power may be transferred in either forward or reverse rotation. The marine transmission forward and reverse drives can be operated by mechanical, hydraulic, pneumatic, or electrically actuated controls.A control valve directs the flow of oil to either the forward or reverse clutch (for forward or reverse operation). The valve is operated by a marine transmission selector lever, which can be remotely operated (from the pilot house), or operated manually at the marine transmission (in the engine room).The marine transmission is usually operated from the pilot house. The pilot house controls must be adjusted in order to permit full travel of the marine transmission selector lever, and full engagement of the clutch plates.With the remote controls properly adjusted, periodic clutch adjustment is not required.Moving and Getting Underway

For best performance and maximum service life, shifting the marine transmission must be done in the following specific manner. To get underway after the engine has started and is warm:1. Fully engage the marine transmission selector lever in the desired direction of travel.2. Wait a sufficient amount of time to allow complete engagement of the clutch. Allow at least three seconds before increasing engine speed.3. Gradually increase engine speed as required.

Operate the marine transmission controls ONLY with the engine running. A rotating propeller shaft with an engaged clutch is not lubricated sufficiently when the engine is not running, and may be damaged.

Docking or Traveling (Direction Change)

Do not shift across the NEUTRAL position without a few seconds delay. The engine