Rating:

Information nipple sub-assy, s Denso

Include in ##:

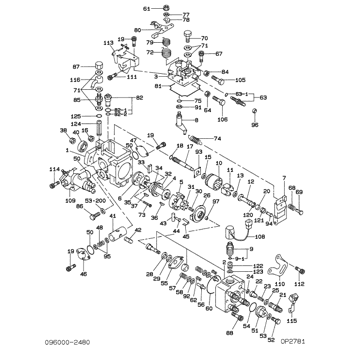

09600-02480

as NIPPLE SUB-ASSY, S

Cross reference number

Part num

Firm num

Firm

Name

09221-80060

22548-6A04

NIPPLE SUB-ASSY, S

0922180060

22548-6A040

TOYOTA

NIPPLE SUB-ASSY, S

0922180060

22548-6A040

TOYOTA

NIPPLE SUB-ASSY, S

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below. Problem

Improper fuel injection results in blown combustion seals in the cylinder. The root cause of the failures are exposed injector wires due to the engine harness rubbing. The software currently does not detect the failure, or the software detects the failure but continues to command fuel injection. The fuel injection has resulted in undesired fuel injected into the cylinder with advanced timing.Solution

New software has been developed to address the problem. Several enhancements were programmed into the software that is listed in Table 1.

Table 1

Application Software

793F High altitude arrangement 291-5485 Engine Ratings Electronic Software Gp

793F Low altitude arrangement 397-6107 Engine Ratings Electronic Software Gp

797F High altitude arrangement 291-5550 Engine Ratings Electronic Software Gp

797F Low altitude arrangement 397-6106 Engine Ratings Electronic Software Gp

797B Retrofit 384-7075 Engine Ratings Electronic Software Gp The features that are designed into the new software and the purposes of the features are listed in Table 2:The software requires a different troubleshooting procedure for -5 Cylinder Injector : Current Below Normal codes. Refer below to ""Troubleshooting the -5 Cylinder Injector : Current Below Normal Code"".Activation of a -5 Cylinder Injector : Current Below Normal affects the pair of injectors that share the supply. Refer to Illustrations 1 and 2 to determine the pairs.Additionally, the injector solenoid test does not provide accurate results for -5 Cylinder Injector : Current Below Normal codes.

Table 2

Feature Purpose

If the exhaust temperature differential between the left and right banks exceeds 50° C (90° F), the E278(2) High Exhaust Differential Temperature is activated. The event stays active. Because the event remains active, multiple repeated logging of the event in the VIMS is prevented. Also, the operator is not distracted by the nuisance of a flashing check engine light.

The debounce time of the 190-8 Engine Speed Sensor : Abnormal Frequency, Pulse Width, or Period was increased. Prevents multiple repeated logging of the event in the ECM and the VIMS.

Updated the conditions for sensing the 342-11 Secondary Engine Speed Sensor : Other Failure Mode diagnostic code. Previously, the condition could only be detected when the camshaft gear was mechanically retarded in relationship to the crankshaft gear. The update includes offset detection during advanced timing.

Conditions for detecting the -7 Injector : Not Responding Properly diagnostic codes were changed. The logic for injector actuation was also changed. Increases the service life of the injectors.

Changed the torque map. Prevents a false lug condition from reducing power and affecting the ability to shift gears

Changed the operation of the Valve Open Test (VOT). The VOT runs automatically every 100 hours in order to measure fuel flow. The fuel injection

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below. Problem

Improper fuel injection results in blown combustion seals in the cylinder. The root cause of the failures are exposed injector wires due to the engine harness rubbing. The software currently does not detect the failure, or the software detects the failure but continues to command fuel injection. The fuel injection has resulted in undesired fuel injected into the cylinder with advanced timing.Solution

New software has been developed to address the problem. Several enhancements were programmed into the software that is listed in Table 1.

Table 1

Application Software

793F High altitude arrangement 291-5485 Engine Ratings Electronic Software Gp

793F Low altitude arrangement 397-6107 Engine Ratings Electronic Software Gp

797F High altitude arrangement 291-5550 Engine Ratings Electronic Software Gp

797F Low altitude arrangement 397-6106 Engine Ratings Electronic Software Gp

797B Retrofit 384-7075 Engine Ratings Electronic Software Gp The features that are designed into the new software and the purposes of the features are listed in Table 2:The software requires a different troubleshooting procedure for -5 Cylinder Injector : Current Below Normal codes. Refer below to ""Troubleshooting the -5 Cylinder Injector : Current Below Normal Code"".Activation of a -5 Cylinder Injector : Current Below Normal affects the pair of injectors that share the supply. Refer to Illustrations 1 and 2 to determine the pairs.Additionally, the injector solenoid test does not provide accurate results for -5 Cylinder Injector : Current Below Normal codes.

Table 2

Feature Purpose

If the exhaust temperature differential between the left and right banks exceeds 50° C (90° F), the E278(2) High Exhaust Differential Temperature is activated. The event stays active. Because the event remains active, multiple repeated logging of the event in the VIMS is prevented. Also, the operator is not distracted by the nuisance of a flashing check engine light.

The debounce time of the 190-8 Engine Speed Sensor : Abnormal Frequency, Pulse Width, or Period was increased. Prevents multiple repeated logging of the event in the ECM and the VIMS.

Updated the conditions for sensing the 342-11 Secondary Engine Speed Sensor : Other Failure Mode diagnostic code. Previously, the condition could only be detected when the camshaft gear was mechanically retarded in relationship to the crankshaft gear. The update includes offset detection during advanced timing.

Conditions for detecting the -7 Injector : Not Responding Properly diagnostic codes were changed. The logic for injector actuation was also changed. Increases the service life of the injectors.

Changed the torque map. Prevents a false lug condition from reducing power and affecting the ability to shift gears

Changed the operation of the Valve Open Test (VOT). The VOT runs automatically every 100 hours in order to measure fuel flow. The fuel injection