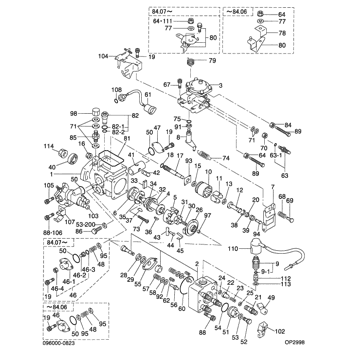

Rating:

Information lever sub-assy, ad Denso

Include in ##:

09600-00823

as LEVER SUB-ASSY, AD

Cross reference number

Part num

Firm num

Firm

Name

09643-53830

22701-1701

LEVER SUB-ASSY, AD

0964353830

22701-17010

TOYOTA

LEVER SUB-ASSY, AD

Information:

Daily

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Air Cleaner - Check service indicator/Service air cleaner when needed Air Starter (If Equipped) - Check lubricator oil level Clutch (If Equipped) - Check/Adjust/Lubricate Marine Transmission - Check oil levelEvery 2550 L (675 gal) of Fuel or 50 Hours

Zinc Rods - Inspect/ReplaceFirst 12,750 L (3375 gal) of Fuel or 250 Hours

1 Valve Lash - Check/Adjust (at the first oil change interval)Every 12,750 L (3375 gal) of Fuel or 250 Hours or Yearly

1 Scheduled Oil Sampling (S O S) - Obtain Sample and analysis1 Engine Crankcase - Replace oil and filter(s)1 Crankcase Breathers - Clean Fuel System - Clean primary fuel filter (if equipped)/Replace final fuel filter Fuel Tank - Drain water and sediment Cooling System (Conventional HD Coolant Only) - Test for SCA concentration OR obtain Level I coolant analysis/Add SCA if necessary Air Cleaner - Clean/Replace air filter elements Belts - Check/Adjust/Replace Hoses and Clamps - Inspect/Replace Batteries - Clean/Check (if required)Every 51,000 L (13,500 gal) Of Fuel Or 1000 Hours

Engine Protection Devices - Inspect/Check Magnetic Pickup - Inspect/AdjustEvery 153,500 L (40,500 gal) Of Fuel Or 3000 Hours

Water Temperature Regulators (Thermostats) - Replace Cooling System (Extended Life Coolant Only) - Add Extender2 Cooling System (Conventional HD Coolant Only) - Drain/Clean/Replace coolant Engine Mounts - Inspect Crankshaft Vibration Damper - Inspect Valve Lash, Valve Rotators - Check/Adjust Fuel Ratio Control, Set Point, and Low Idle - Check/Adjust PAR Analysis - ObtainEvery 256,000 L (67,500 gal) Of Fuel Or 5000 Hours

Fuel Injection Nozzles - Test/Exchange Jacket Water Pump - Inspect/Rebuild or Exchange Raw/Sea Water Pump - Inspect/Rebuild or Exchange Alternator - Inspect/Rebuild or Exchange Starting Motor - Inspect/Rebuild or Exchange Air Compressor (If Equipped) - Inspect/Rebuild or Exchange Turbocharger - Clean/Inspect/CheckEvery 6000 Hours Or Four Years

Cooling System (Extended Life Coolant Only) - Drain/Flush/Replace CoolantOverhaul

Overhaul Considerations13408 Marine Engines that are equipped with the deep oil sump [87 L (92 qt)] may perform this maintenance after 25,500 L (6750 gal) of fuel or 500 Hours.2If a commercial HD coolant/antifreeze meeting ASTM D4985 specifications is used, or if a mixture of commercial SCA and water is used, this maintenance should be performed at a maximum of One Year.

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Air Cleaner - Check service indicator/Service air cleaner when needed Air Starter (If Equipped) - Check lubricator oil level Clutch (If Equipped) - Check/Adjust/Lubricate Marine Transmission - Check oil levelEvery 2550 L (675 gal) of Fuel or 50 Hours

Zinc Rods - Inspect/ReplaceFirst 12,750 L (3375 gal) of Fuel or 250 Hours

1 Valve Lash - Check/Adjust (at the first oil change interval)Every 12,750 L (3375 gal) of Fuel or 250 Hours or Yearly

1 Scheduled Oil Sampling (S O S) - Obtain Sample and analysis1 Engine Crankcase - Replace oil and filter(s)1 Crankcase Breathers - Clean Fuel System - Clean primary fuel filter (if equipped)/Replace final fuel filter Fuel Tank - Drain water and sediment Cooling System (Conventional HD Coolant Only) - Test for SCA concentration OR obtain Level I coolant analysis/Add SCA if necessary Air Cleaner - Clean/Replace air filter elements Belts - Check/Adjust/Replace Hoses and Clamps - Inspect/Replace Batteries - Clean/Check (if required)Every 51,000 L (13,500 gal) Of Fuel Or 1000 Hours

Engine Protection Devices - Inspect/Check Magnetic Pickup - Inspect/AdjustEvery 153,500 L (40,500 gal) Of Fuel Or 3000 Hours

Water Temperature Regulators (Thermostats) - Replace Cooling System (Extended Life Coolant Only) - Add Extender2 Cooling System (Conventional HD Coolant Only) - Drain/Clean/Replace coolant Engine Mounts - Inspect Crankshaft Vibration Damper - Inspect Valve Lash, Valve Rotators - Check/Adjust Fuel Ratio Control, Set Point, and Low Idle - Check/Adjust PAR Analysis - ObtainEvery 256,000 L (67,500 gal) Of Fuel Or 5000 Hours

Fuel Injection Nozzles - Test/Exchange Jacket Water Pump - Inspect/Rebuild or Exchange Raw/Sea Water Pump - Inspect/Rebuild or Exchange Alternator - Inspect/Rebuild or Exchange Starting Motor - Inspect/Rebuild or Exchange Air Compressor (If Equipped) - Inspect/Rebuild or Exchange Turbocharger - Clean/Inspect/CheckEvery 6000 Hours Or Four Years

Cooling System (Extended Life Coolant Only) - Drain/Flush/Replace CoolantOverhaul

Overhaul Considerations13408 Marine Engines that are equipped with the deep oil sump [87 L (92 qt)] may perform this maintenance after 25,500 L (6750 gal) of fuel or 500 Hours.2If a commercial HD coolant/antifreeze meeting ASTM D4985 specifications is used, or if a mixture of commercial SCA and water is used, this maintenance should be performed at a maximum of One Year.